Principle of operation of the CHP generator. New coal burning technologies

The principle of operation of the heat-power center (CHP) is based on the unique property of the water vapor - to be a coolant. In a preheated state, being under pressure, it turns into a powerful source of energy, leading to the movement of the turbine of thermal power plants (TPP) - the legacy of such a distant era of steam.

The first thermal power station was built in New York on Pearl Street (Manhattan) in 1882. The homeland of the first Russian thermal station, a year later, was St. Petersburg. Something strange, but even in our age of high technologies, the TPP has not found a full-fledged replacement: their share in world energy is more than 60%.

And this is a simple explanation in which the advantages and disadvantages of thermal energy are concluded. Its "blood" - organic fuel - coal, fuel oil, combustible shale, peat and natural gas are still relatively available, and their reserves are large enough.

The big minus is that fuel combustion products cause serious harm to the environment. And the natural pantry once finally exhausted, and thousands of TPP will turn into rust "monuments" of our civilization.

Principle of operation

First you should decide on the terms "CHP" and "TPP". Speaking of understandable language - they are native sisters. "Pure" thermal power plant - TPP is calculated solely on the production of electricity. Its other name "Condensation Power Station" - KES.

Thermal-power center - CHP - a variety of TPP. It, in addition to generating electricity, is supplying hot water to the central heating system and for household needs.

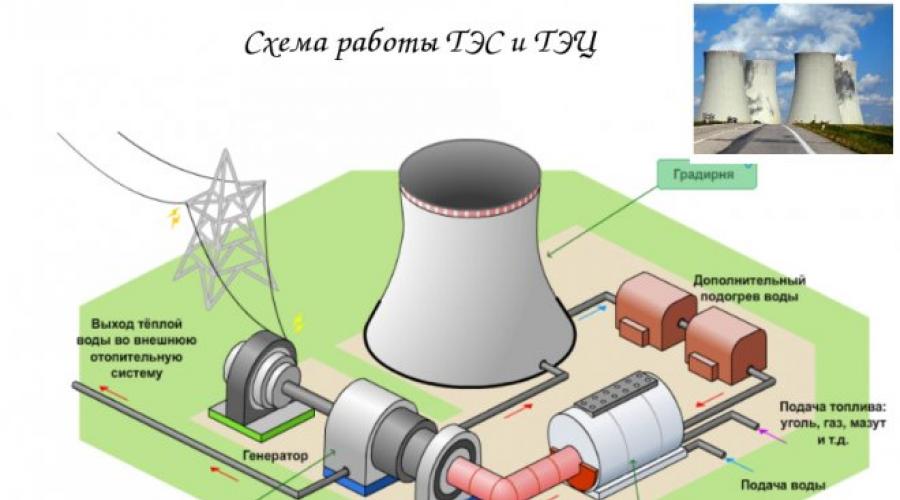

The CHP operation scheme is quite simple. Fuel and heated air are in the firebox - oxidizing agent. The most common fuel on the Russian CHP is chopped coal. The heat from the combustion of coal dust turns the water entering the copper in the steam, which then under pressure is supplied to the steam turbine. The powerful flow of the pair causes it to rotate, leading the generator rotor into motion, which converts mechanical energy into electrical.

Further, steam, already significantly lost its initial indicators - the temperature and pressure - enters the condenser, where after the cold "water soul" it becomes water again. Then the condensate pump pumps it into regenerative heaters and then in Deaerator. There, water is exempt from gases - oxygen and CO 2, which can cause corrosion. After that, the water is again heated from the steam and is fed back to the boiler.

Heat supply

The second, no less important function of the CHP - ensuring hot water (ferry) intended for central heating systems nearby settlements and domestic use. In special heaters, cold water is heated to 70 degrees in summer and 120 degrees in winter, after which the network pumps are supplied to the general mixing chamber and then on the thermal chamber system enters consumers. Water reserves on CHP are constantly replenished.

How the TPPs work on gas

Compared to coal CHP, TPP, where gas turbine installations are installed, are much more compact and environmentally friendly. Suffice it to say that such a station does not need a steam boiler. The gas turbine installation is essentially the same turbojet aircorder, where, in contrast, the reactive jet is not thrown into the atmosphere, but rotates the generator rotor. In this case, emissions of combustion products are minimal.

New coal burning technologies

The efficiency of modern CHP is limited 34%. The absolute majority of thermal power plants still work on the corner, which is explained very simple - the reserves of coal on Earth are still enormous, therefore the share of TPPs in the total amount of electricity produced is about 25%.

The process of burning coal For many decades remains almost unchanged. However, new technologies came here.

The peculiarity of this method is that instead of air as an oxidizing agent, a clean oxygen is used as an oxidizing agent when combusting coal dust. As a result, a harmful impurity is removed from flue gases - NOx. The remaining harmful impurities are filtered in the process of several cleaning steps. The remaining at the output of CO 2 is pumped in tanks under high pressure and is subject to burial at a depth of 1 km.

OXYFUEL CAPTURE method

Here, also when burning coal, pure oxygen is used as an oxidizing agent. Only in contrast to the previous method at the time of the combustion, steam is formed, leading the turbine into rotation. Then from flue gases are removed ash and sulfur oxides, cooling and condensation is made. The remaining carbon dioxide under pressure 70 atmospheres is translated into a liquid state and placed under the ground.

"Pre-Combucer" method

Coal is burned in the "ordinary" mode - in the boiler in a mixture with air. After that, the ash and SO 2 - sulfur oxide are removed. Next, the removal of CO 2 takes place with a special liquid absorbent, after which it is disposed of by burial.

Five of the most powerful thermal power plants in the world

The championship belongs to the Chinese TPECTUO TPEC with a capacity of 6600 MW (5 en / bl. X 1200 MW), which occupies an area of \u200b\u200b2.5 square meters. km. It follows her "compatriot" - Taichung TPP with a capacity of 5824 MW. Troika leaders closes the largest Surgut GRES-2 in Russia - 5597.1 MW. In the fourth place, the Polish Belhatuvskaya TPP - 5354 MW, and the fifth - Futtsu CCGT Power Plant (Japan) - a gas TPP with a capacity of 5040 MW.

5.7. The organizational structure of the management of the CHP and the main functions of the staff

In power plants, administrative and economic, production and technical and operational dispatch controls take place.

The administrative and economic authority is the director. In direct submission it is one of the main departments of the CHP - the planning and economic department of PEO.

PEO is managed by production planning. The main task of production planning is the development of promising and current operating plans of CHP and control over the implementation of scheduled indicators.

Accounting CHP carries out accounting of monetary and material means of the station; Personnel payroll calculations (settlement part), current financing (banking operations), calculations on contracts (with suppliers), drawing up accounting reporting and balance sheets, and compliance with financial activities.

In jurisdiction of the material and technical supply department there is a station supply to all the necessary operational materials, spare parts and materials, tools for repair.

The personnel department is engaged in recruitment and study of personnel, make up the reception and dismissal of workers.

The technical leader of the CHP is the first deputy director - chief engineer. In the immediate submission it is the production and technical department of PTO.

PTO CHP develops and implements measures to improve production, produces operational and commissioning equipment testing, develops operational norms and regime cards of equipment, develops with PEO annual and monthly technical plans and planned tasks for individual aggregates and maintains consumption of fuel, water, electricity; This is the technical reporting of CHP. The FTO has three main groups: technical (energy) accounting (TU), setup and testing (nor), repair and design (RK). The main production includes workshops: electrical, turbine and boiler, etc.

In addition to the main production, we consider auxiliary production. The auxiliary workshops on the CHP include: the heat automation and measurements of TAI, the heat supply site and underground sewage system, in which the station workshops, heating and ventilation plants of production and service buildings, sewage are underway. The repair and construction workshop, which carries out operational supervision of industrial and service buildings and their repair, is working on maintenance in the proper form of roads and the entire CHP area. All CHPS (basic and auxiliary) are subject to administrative and technical terms obey the chief engineer. The head of each workshop is the head of the workshop, subordinate to all production and technical issues the chief engineer of the station, and according to the administrative and economic director of the CHP.

Energy equipment of workshops is served by workshop operational duty officers organized in replaceable brigades. The work of each shift is guided by the duty heads of the change of the main workshops, subordinate to the head of the change of station (NSS).

The NSS carries out the operational management of all duty operating personnel of the station during the shift. The NSS in administrative-technical is subject to the energy system dispatcher on duty and performs all its orders for the operational management of the CHP production process.

In operational relations, the NSS is the uniform at the station for the relevant shift, and its orders are performed by replaceable attendant personnel through the relevant heads of changing the main workshops. In addition, the station duty engineer immediately responds to all malfunctions in the workshops and takes measures to eliminate them.

5.8. Drawing up a business plan

5.8.1. Project development goals

This section of the project contains information on the technical and economic feasibility of the project of a new power plant.

CHP is located in Eastern Siberia. The power plant is designed for the electro and heat supply of the industrial area. The total electric load of consumers in the area of \u200b\u200baccommodation is approximately 50 MW. CHP fully provides local load, and excess power transmits to the system. The station is connected to the system along the power line with a voltage of 110 kV.

The industrial area before the construction of the CHP received electricity from neighboring power systems. In order to eliminate the dependence on neighboring power systems, an open joint-stock company is being created, which will carry out the construction and operation of the CHP and sell electricity from the power plant tires in the power system. The latter is a JSC that performs the distribution of electricity and bring it to consumers.

The purpose of the establishment of CHP AO is to obtain high profits on the share of capital and ensuring reliable and economical energy supply of consumers.

By voltage: UUST \u003d UR - by current: IMAX< Iуст 2,8868< 4,125 - по роду установки: внутренней. Выбираем реактор типа РБДГ-10-4000-0,18 9 ВЫБОР АППАРАТОВ И ТОКОВЕДУЩИХ ЧАСТЕЙ ДЛЯ ЗАДАННЫХ ЦЕПЕЙ 9.1 Выбор сборных шин и ошиновки на стороне 220 кВ. - Провести выбор сечения сборных шин по допустимому току при максимальной нагрузки на шинах. - Выбираем провод АС 240/32 ...

The condition of the post -avary regime, if the current is smaller or equal to A. A. Condition is performed, the line gain is not required. The main scheme of electrical connections of substations depends on the following factors ...

October 24, 2012.Electric energy has long entered our lives. Another Greek philosopher Fales in the 7th century BC discovered that amber, shabby about wool begins to attract objects. But for a long time, no one paid attention to this fact. Only in 1600, the term "electricity" appeared for the first time, and in 1650 Otto, St. Gereica created an electrostatic machine in the form of a sulfur stem, which made it possible to observe not only the effect of attracting, but also the repellent effect. It was the first simplest electrostatic machine.

Many years have passed since then, but even today, in the world filled with terabytes of information when you can find out everything that interests you, for many, it remains a mystery as electricity is made, as it is delivered to us in the house, office, to the enterprise ...

In several parts, consider these processes.

Part I. Generation of electrical energy.

Where does the electrical energy come from? This energy appears from other types of energy - thermal, mechanical, nuclear, chemical, and many others. In an industrial scale, electrical energy is obtained on power plants. Consider only the most common types of power plants.

1) Thermal power plants. Today from can be combined with one term - GRES (State District Power Plant). Of course, today this term lost its initial meaning, but he did not go to eternity, but remained with us.

Thermal power plants are divided into several subtypes:

BUT) Condensation Power Station (CAC) - a thermal power plant producing only electrical energy, this type of power plants is obliged to the features of the principle of work.

The principle of operation: air and fuel (gaseous, liquid or solid) are supplied to the boiler using pumps. The fuel-air mixture is obtained, which burns in the firebox of the boiler, highlighting a huge amount of heat. At the same time, water passes through the pipe system, which is located inside the boiler. The released heat is transmitted to this water, with its temperature rises and is brought to a boil. Couple, which was obtained in the boiler again goes into the boiler to overheat it above the boiling point of water (at this pressure), then on steam pipelines it enters the steam turbine in which the pair does work. In this case, it expands, its temperature and pressure decreases. Thus, the potential energity of the steam is transmitted to the turbine, and therefore turns into kinetic. The turbine, in turn, leads to a rotor of a three-phase alternating current generator, which is on the same shaft with a turbine and produces energy.

Consider some Elements of the KES closer.

Steam turbine.

The flow of the water vapor enters through the guide devices to curvilinear blades, fixed in the circumference of the rotor, and, affecting them, leads the rotor into rotation. Between the rows of blades, as you can see, there are gaps. They are because this rotor is removed from the housing. The rows of blades are also built into the housing, but they are still and serve to create the desired angle of falling a couple on moving blades.

Condensation steam turbines are served to transform the maximum possible part of the heat of steam into mechanical work. They work with the release (exhaust) of the spent steam into the capacitor, in which the vacuum is supported.

Turbine and generator that are on the same shaft are called a turbogenerator. Three-phase alternator AC (synchronous machine).

It consists of:

Which increases the voltage to the standard value (35-110-220-330-500-750 kV). At the same time, the current is significantly reduced (for example, with an increase in voltage by 2 times, the current decreases 4 times), which allows you to transmit power over long distances. It should be noted that when we talk about the class of voltage, then we mean a linear (interpasal) voltage.

The active power that the generator produces is regulated by changing the amount of energy, while the current changes in the rotor winding. To increase the output active power, you need to increase the steam supply to the turbine, while the current in the rotor winding will increase. We should not forget that the generator is synchronous, and this means that its frequency is always equal to the frequency of the current in the power system, and the change in the parameters of the energy carrier will not affect the frequency of its rotation.

In addition, the generator also produces reactive power. It can be used to regulate the output voltage in small limits (that is, it is not a basic means of voltage control in the power system). It works this way. With the overexcitation of the rotor winding, i.e. With an increase in the voltage on the rotor above the nominal, the "excess" of the reactive power is issued in the power system, and when the rotor winding is not acceptable, then the reactive power is consumed by the generator.

Thus, in alternating current, we are talking about complete power (measured in Volt-amperes - BA), which is equal to the root square from the amount of active (measured in watts - W) and reactive (measured in the volt-amperes of jet - Var) capacity.

Water in the reservoir serves to drive heat from the condenser. However, spray pools are used often for these purposes.

or cooling towers. The cooling towers are the tower Fig. 8

or fan Figure 9.

The cooling towers are arranged almost as well as, with the only difference that water flows through radiators, transmits them heat, and they are already cooled by the injected air. In this case, part of the water evaporates and carries into the atmosphere.

The efficiency of such a power plant does not exceed 30%.

B) gas turbine power plant.

On a gas turbine power plant, the turbogenerator is driven not by steam, but directly by the gases obtained during fuel combustion. At the same time, it is possible to use only natural gas, otherwise the turbine will quickly be out of standing because of its contamination by combustion products. Efficiency at maximum load 25-33%

A much greater efficiency (up to 60%) can be obtained by combining steam and gas cycles. Such installations are called vapor. Instead of a conventional boiler, a recycle boiler is installed, which does not have its own burners. He gets warm from the exhaust gas turbine. Currently, PSU is actively being introduced into our lives, but so far there are few of them in Russia.

IN) Thermal-power center (very long time has become an integral part of large cities).Fig.11

CHP is structurally arranged as a condensation power plant (CAC). The peculiarity of the power plant of this type is that it can produce both thermal and electrical energy. Depending on the type of steam turbine, there are various ways of selected steam, which allow couples from it with different parameters. In this case, part of the pair or completely all pairs (depending on the type of turbine) enters the network heater, gives it warmth and condenses there. Thermal turbines allow you to adjust the amount of steam for thermal or industrial needs, which allows the CHP to work in several load modes:

thermal - the production of electrical energy is completely dependent on the production of steam for industrial or heat efficient needs.

electric - electrical load is independent of thermal. In addition, the CHP can work in fully condensation mode. This may be required, for example, with a sharp shortage of active power in the summer. Such a mode is disadvantageous for the CHP, because The efficiency is significantly reduced.

The simultaneous production of electrical energy and heat (cogeneration) is a favorable process at which the PD of the station is significantly increasing. For example, the settlement efficiency of the COP is a maximum of 30%, and the CHP is about 80%. Plus, cogeneration allows you to reduce idle thermal emissions, which has a positive effect on the ecology of the area in which the CHP is located (compared to the case, if there was a similar power KP).

Consider a Read more steam turbine.

Thermal steam turbines include turbines with:

Refractive;

Adjustable selection of steam;

Selection and backup.

Turbines with backpressure work with the exhaust of the pair not into the capacitor, like the KES, and in the network heater, that is, all the couples, which went through the turbine, goes to heat intake. The design of such turbines has a significant disadvantage: the electrical load schedule depends entirely on the thermal load schedule, that is, such devices cannot take part in the operational regulation of the current frequency in the power system.

In turbines having adjustable selection of steam, it takes place in the desired quantity in the intermediate steps, while choosing such steps to select the steam, which are suitable in this case. This type of turbine has independence from heat load and regulation of the output active power can be adjusted in large limits than that of the CHP with the back pressure.

Turbines with selection and backpressure combine the features of the first two types of turbines.

CHP thermal turbines are not always capable of changing heat load over a short time. To cover the peaks of the load, and sometimes to increase electrical power by transferring turbines into condensation mode, peak water boilers are installed on the CHP.

2) Nuclear power plants.

In Russia, currently there are 3 types of reactor installations. The general principle of their work is approximately similar to the work of the KES (in the former times of NPPs called GRES). The fundamental difference consists of only that thermal energy is obtained not in boilers on organic fuel, but in nuclear reactors.

Consider the two most common types of reactors in Russia.

1) Reactor RBMK.

A distinctive feature of this reactor is that steam to rotate the turbine are obtained directly in the active zone of the reactor.

Active zone of RBMK. Fig.13.

it consists of vertical graphite columns in which there are longitudinal holes, with pipes from zirconium alloy and stainless steel inserted there. Graphite performs the role of neutron moderator. All channels are divided into fuel and SUV channels (control and protection system). They have different cooling contours. In the fuel channels insert a cassette (TVS - a fuel assembly) with rods (fuel-fuel element) inside which there are uranium tablets in a hermetic shell. It is clear that it is from them that they receive heat energy, which is transmitted continuously circulating bottom to the coolant under high pressure - ordinary, but very well purified from impurities.

Water, passing through the fuel channels, partially evaporates, the steaming mixture comes from all individual fuel channels in 2 drum separators, where the separation (separation) of the water is separated. Water again goes into the reactor with the help of circulating pumps (from 4 to the loop), and steam on steam pipelines goes to 2 turbines. The steam is then condensed in the condenser, turns into water that goes back to the reactor.

The thermal capacity of the reactor is controlled only with neutron rods from boron, which moved to the SUZ channels. Water cooling these channels is downward.

As you might notice, I have never said about the reactor hull. The fact is that in fact, RBMK has no hull. The active zone about which I now told you placed in a concrete mine, it is closed with a cover with a weight in 2000 tons.

The above figure shows the upper biological protection of the reactor. But you should not expect that lifting one of the blocks, it will be possible to see the yellow-green age of the active zone, no. The lid itself is located significantly lower, and above it, in space to the upper biological protection there is a gap for communications and fully extracted rods of absorbers.

Between graphite columns leave space for thermal expansion of graphite. In this space, a mixture of nitrogen and helium gases is circulated. According to her, they judge the tightness of the fuel channels. The active zone of RBMK is designed for a break of no more than 5 channels, if it is unloaded more - the reactor cover and the disclosure of the remaining channels will occur. Such a development of events will cause the repetition of the Chernobyl tragedy (here I mean not the technogenic catastrophe itself, but its consequences).

Consider the advantages of RBMK:

- Thanks to the extinct control of thermal power it is possible to change fuel assemblies without stopping the reactor. Every day, usually change multiple assemblies.

- Low pressure in KMPC (contour of multiple forced circulation), which contributes to a softer course of accidents associated with its depressurization.

- Associate a complex in the manufacture of the reactor housing.

Consider minuses of RBMK:

-In the course of operation discovered numerous miscalculations in the geometry of the active zone, to eliminate which on the operating power units of the 1st and 2nd generations (Leningrad, Kursk, Chernobyl, Smolensk) are not fully possibly. The power units of the RBMK 3rd generation (it is one - on the 3 power unit of the Smolensk NPP) deprived of these shortcomings.

Oreactor one-connecting. That is, the turbine rotates steam, obtained directly in the reactor. This means that it contains radioactive components. When the turbine is deployed (and it was at the Chernobyl nuclear power plant in 1993), its repair will be very complicated, and maybe it is impossible.

- The reactor service is determined by graphite service life (30-40 years). Then his degradation occurs, manifested in his swelling. This process already causes serious concerns on the oldest power unit of RBMK Leningrad-1, built in 1973 (he has already been 39 years old). The most likely way out of the situation is the durability of the n-number channels to reduce thermal expansion of graphite.

-Graphite moderator is a flammable material.

-The bottom of the huge number of shut-off reinforcement, the reactor is complex in control.

- On 1 and 2 generations there is instability when working at low facilities.

In general, we can say that RBMK is a good reactor for its time. Currently, it is decided not to build power units with this type of reactor.

2) VVER reactor.

A VVER comes to replace RBMK. It has significant advantages compared to RBMK.

The active zone is completely in a very durable case, which is manufactured at the factory and bring railway, and then by road to the power unit under construction in a fully prepared form. The retarder is pure water under pressure. The reactor consists of 2-circuits: the water of the first circuit under high pressure cools the fuel assemblies, transmitting the heat of the 2nd contour using the steam generator (performs the function of the heat exchanger between 2 insulated circuits). In it, the water of the second contour boils, turns into steam and goes to the turbine. In the first circuit, water does not boil, as it is under very large pressure. The spent steam condenses in the condenser and goes to the steam generator. The two-circuit scheme has significant advantages compared to one-contact:

Couple going to the turbine is not radio.

The power of the reactor can be controlled not only by the stems-absorbers, but also a solution of boric acid, which makes the reactor more stable.

The elements of the first contour are located very closely from each other, so they can be placed in the overall protective shell. When ruptures in the first circuit, radioactive elements will fall into the gerocket and will not enter the environment. In addition, the producer protects the reactor from external influence (for example, from the fall of a small aircraft or explosion over the perimeter of the station).

The reactor is not complicated in control.

There are also cons:

-In the difference from RBMK, the fuel cannot be changed when the reactor is running, because It is in a common case, and not in separate channels, as in RBMK. The rebooting time of fuel usually coincides with the time of the current repairs, which reduces the effect of this factor to the KiUM (the coefficient of the installed power).

-First contour is under great pressure, which can potentially cause a larger scale of the accident during depressurization than RBMK.

- The reactor is very difficult to transport the manufacturer from the factory to the NPP construction site.

Well, we looked at the work of thermal power plants, now consider work

The principle of operation of the HPP is quite simple. The circuit of hydraulic structures provides the necessary water pressure coming on the hydroturgic blades, which drives the generators producing electricity.

The necessary water pressure is formed by the construction of the dam, and as a consequence of the concentration of the river in a certain place, or derivation - the natural flow of water. In some cases, for the preparation of the necessary water pressure, they are used together and dam, and derivation. HPP have very high maneuverability of power generated, as well as the low cost of electricity produced. This feature of the HPP led to the creation of another type of power plant - GESS. Such stations are capable of accumulating generated electricity, and to let it go into the moments of peak loads. The principle of operation of such power plants is as follows: during certain periods (usually at night), GESOP hydraulic units operate as pumps, consuming electrical energy from the power system, and pump water into specially equipped upper pools. When the need arises (in the peaks of the load), water from them enters the pressure pipeline and activates the turbine. Gaes perform an extremely important function in the power system (frequency regulation), but they do not get widespread in our country, because As a result, they consume more power than they give. That is, the station of this type is unprofitable for the owner. For example, on the Zagorsk Gaes power of hydrogenerators in generator mode of 1200 MW, and in the pump - 1320 MW. However, this type of station is best suited for rapidly increase or decrease in power generated, so they are profitable to build about, for example, nuclear power plants, as the latter work in the basic mode.

We looked at exactly how to produce electrical energy. It's time to ask yourself a serious question: "And what type of stations best meets all the modern requirements for reliability, environmental friendliness, and besides this, will also be distinguished by a small value of energy?" Each will answer this question in different ways. I will give your list of the "best of the best."

1) CHP on natural gas. The efficiency of such stations is very high, high and the cost of fuel, but natural gas is one of the most "clean" types of fuel, and this is very important for the ecology of the city, which is usually located and the CHP is usually located.

2) HPP and GESS. Benefits over thermal stations are obvious, since this type of station does not pollute the atmosphere and produces the most "cheap" energy, which plus everything is a renewable resource.

3) PGU on natural gas. The highest efficiency among heat stations, as well as a small amount of fuel consumed, will allow partially solve the problem of thermal pollution of the biosphere and bounded stocks of fossil fuels.

4) NPP. In normal operation, the NPP discardes in the environment of 3-5 times less radioactive substances than the thermal station of the same power, so the partial replacement of thermal power plants atomic is quite justified.

5) GRES. Currently, natural gas is used at such stations as fuel. This is absolutely meaningless, since with the same success in the FIR furnaces, you can dispose of passing petroleum gas (APG) or burn coal, the reserves of which are huge, compared with natural gas reserves.

On this I complete the first part of the article.

Material prepared:

student Group ES-11B UZGU AGIGALOV Sergey.

CHP - a thermal power plant that produces not only electricity, but also gives heat to our houses in winter. On the example of the Krasnoyarsk CHP, let's see how almost any thermal power plant works.

In Krasnoyarsk there are 3 thermal power plants, the total electrical power of which is only 1146 MW. In the title photography, 3 flue pipes CHP-3 can be seen, the height of the highest of them is 275 meters, the second in height is 180 meters.

The abbreviation of the CHP itself implies that the station produces not only electricity, but also heat (hot water, heating), moreover, heat generation is possible even more priority in our famous harsh winters.

Simplified the principle of operation of the CHP can be described as follows.

It all starts with fuel. The role of fuel on different power plants can be coal, gas, peat. In our case, this is a brown coal from the Borodino cut, located 162 km from the station. Coal is brought by rail. Part it is stored, the other part goes through conveyors in the power unit, where the coal itself is first crushed to dust and then served in the combustion chamber - steam boiler.

The car pipeline by which coal is poured into the bunker:

Here coal is crushed and falls into the "fire":

Steam boiler - This is an aggregate to obtain steam with a pressure above atmospheric from the continuously entering the nutrient water. This is due to the heat released during the combustion of fuel. The boiler itself looks pretty impressive. On the Krasnoyarsk CHP-3, the height of the boiler is 78 meters (26-storey house), and it weighs more than 7,000 tons! Boiler performance - 670 tons of steam per hour:

View from above:

Incredible number of pipes:

Clearly visible drum boiler. The drum is a cylindrical horizontal vessel having water and steam volumes that are separated by a surface called evaporation mirror:

Cooled flue gases (approximately 130 degrees) come out of the firebox to electrostilifers. In the electrostatic precipitors, gas is cleaned from ash, and purified smoke goes into the atmosphere. The effective degree of purification of flue gases is 99.7%.

In the photo are the most electrostilifers:

Passing through steamper steampers, heats up to a temperature of 545 degrees and enters the turbine, where the turbogenerator rotor rotates under pressure and, accordingly, electricity is produced.

The disadvantage of the CHP is that they should be built not far from the end user. The gasket of the heat paints is worth a huge amount of money.

In the Krasnoyarsk CHP-3, a direct-flow water supply system is used, that is, water for cooling the capacitor and use in the boiler is taken directly from the Yenisei, but before that it passes clean. After use, the water returns to the channel back in Yenisei.

Turbogenerator:

Now a little about the most Krasnoyarsk CHP-3.

The construction of the station began back in 1981, but, as in Russia, it happens, because of the crises, the CHP did not work on time. From 1992 to 2012, the station worked as a boiler room - heated water, but electricity learned only on March 1 last year. About 560 people work on the CHP.

Dispatcher:

Even on the Krasnoyan CHPP-3, 4 water boilers are functioning:

Peephole in the furnace:

And this photo is removed from the roof of the power unit. A large pipe has a height of 180m, the one is smaller - the trumpet of the starting boiler room:

By the way, the highest chimney in the world is located on power plants in Kazakhstan in Ekibastuz. Its height is 419.7 meters. That's her:

Transformers:

Inside the ZRUE building (closed switchgear with Eleginazova insulation) by 220 sq.:

General view of the distribution device:

That's all. Thanks for attention.

Heat electrofentral (CHP)

The greatest distribution of CHP received in the USSR. The first heat pipes were laid from the power plants of Leningrad and Moscow (1924, 1928). From the 30s. Design and construction of CHP capacity of 100-200 MW. By the end of 1940, the power of all operating CHP reached 2 GW annual release of heat - 10 8 GJ And the length of thermal networks (see the thermal network) - 650 km. In the mid-70s. The total electric power of the CHP is about 60 GW (with the total power of power plants of thermal power plane 220 and thermal power plants of thermal electrical electrical components 180 GW). The annual electricity generation at the CHP reaches 330 billion. kvch, Heat vacation - 4.10 9 GJ; Power of individual new CHP - 1.5-1.6 GWwith the watch of heat leave to (1.6-2.0) .10 4 GJ; Specific electricity generation upon vacation 1 GJ. Heat - 150-160 kWh. Specific consumption of conditional fuel for production 1 kWh. Electricity averages 290 g. (whereas on GRES - 370 g.);

The smallest average annual specific consumption of conditional fuel at the CHP about 200 g / kvch (on the best GRES - about 300 g / kvch). Such a reduced (compared to GRES) The specific fuel consumption is due to the combined production of the energy of two types using the heat of the spent steam. In the USSR, CHES gives savings to 25 million. t. Conditional fuel per year (heat-power center 11% of the entire fuel coming into electricity production). CHP - the main production link in the system of centralized heat supply. The construction of the CHP is one of the main directions for the development of the energy economy in the USSR and other socialist countries. In capitalist countries, the CHP has limited distribution (mainly industrial CHP). LIT: Sokolov E. Ya., Heat Protection and thermal networks, M., 1975; Ryzhkin V. Ya., Heat electric stations, M., 1976. V. Ya. Ryzhkin.

Great Soviet Encyclopedia. - M.: Soviet Encyclopedia. 1969-1978 .

Synonyms:Watch what is "heat-power center" in other dictionaries:

- (CHP), a steam turbine thermal power plant, generating and released by consumers at the same time 2 types of energy: electrical and thermal (in the form of hot water, steam). In Russia, the power of individual CHP reaches 1.5 1.6 GW at the watch ... ... Modern encyclopedia

- (CHP thermal power plant), a thermal power plant generating not only electrical energy, but also heat released by consumers in the form of steam and hot water ... Big Encyclopedic Dictionary

Heat-power center, and, wives. Thermal power plant generating electricity and heat (hot water, steam) (CHP). Explanatory dictionary of Ozhegov. S.I. Ozhegov, N.Yu. Swedov. 1949 1992 ... Explanatory Dictionary of Ozhegova Large Polytechnic Encyclopedia

CHP 26 (South CHP) in Moscow ... Wikipedia