Closed cycle of water supply and treatment facilities. Closed technological cycle

Read also

In recent years, the markets for clean energy have grown at an extremely high rate, and not only scientists, but also companies that invest in finding solutions to environmental problems, contribute to the development of new technologies and the creation of alternative fuels. To preserve natural resources, there is a search for new types of biofuels. The third generation of plant materials that can be used for energy production is already considered to be algae. Investments in ecology can be considered not only direct environmental protection measures, but also investments in resource-saving restructuring, low-waste and non-waste technologies.

Sources of environmental hazard are the development of mineral deposits and the construction of oil and gas pipelines, industry using old technologies, the concentration of vehicles and irrational use of natural resources, leading to the transformation of natural resource potential. In addition, the region's climate - too hot in summer and cold in winter - often causes environmental instability.

One of the directions of greening economic development is the widespread development of low-waste and resource-saving technologies. The purpose of their development is the creation of closed technological cycles with full use of incoming raw materials and waste. The company AgroSib-Razdolye also resorted to the technology of waste-free production, which began to produce fuel briquettes from sunflower husks in the Altai Territory.

Waste-free production

Previously, the AgroSib-Razdolye enterprise produced oil and meal - concentrated feed for poultry and livestock farms. Over the past year, the company's capacities have grown, and the question arose about the expedient use of waste from the main production. “Today we process 600 thousand tons of sunflower seeds. The amount of husk removed has increased. The boiler room is working to its limit. So the need arose to dispose of the husk ", - says the General Director of AgroSib-Razdolye Vladimir Anipchenko.

AgroSib-Razdolye spent 17 million rubles on the purchase of equipment and the launch of the production of fuel briquettes. The payback period of the project is estimated at one and a half years.

The fuel briquettes themselves are small cylinders up to 12 centimeters in diameter and up to 30 centimeters long. Today AgroSib-Razdolye produces up to 20 tons of briquettes per day, but with an increase in the volume of oil produced, the fuel production capacity will also change. “As far as we know, in the Altai Territory they also produce fuel from sawdust of woodworking waste, but not in briquettes, but in pellets. Altai also has a production of fuel pellets from oat husks ", - says the marketing analyst of the company Evgeniya Vasilieva.

According to the program coordinator of the charitable organization "Siberian Ecological Center" Alexandra Dubynina, agricultural waste should be a feedstock for biofuel production and be included in the cycle of resource use. “There is a tendency in the world - a company that produces any product should also be responsible for waste disposal. One way or another, we must go into such closed cycles - produced and processed. Of course, it is necessary to calculate how beneficial it is for the enterprise, but from an environmental point of view, any such projects are important, and we must support them in every possible way, and the state should provide the best possible conditions, if it is a small business, give grants or interest-free loans, ”comments Dubynin.

According to Vasilyeva, there is still no great demand for biofuel from husk, there is only interest so far. “The interest is quite big, we receive calls. The product is innovative in any case, it requires a lot of explanatory and educational work, because people need to show and prove what the benefits are, what advantages this fuel has over others. But the demand has not yet fully formed, the market is in its infancy, ”the marketer sighs.

Speaking about the new technology, Evgenia Vasilyeva makes a reservation: husk processing is not an invention of the Altai plant. Oil extraction plants, which also produce biofuel from husk, operate in the European and southern parts of Russia. “But this is a novelty in the Altai Territory and in Siberia in general,” she adds.

You can use husk fuel briquettes instead of firewood or coal both in a private house and in small boilers that heat villages or administrative institutions: schools, hospitals. Firewood and coal can be replaced or supplemented with these fuel briquettes.

Instead of firewood and coal

Wood, which is itself a biofuel, is a renewable resource. Nowadays, energy forests are grown in the world for the production of firewood or biomass, consisting of fast-growing species such as, for example, poplar. In Russia, wood and biomass are mainly used for pulpwood, which is not suitable for the production of sawn timber.

Fuel pellets and briquettes are replacing firewood - pressed products from wood waste (sawdust, wood chips, bark), straw, agricultural waste (sunflower husks, nutshells) and other biomass. Wood fuel pellets are called pellets, they are small - up to three centimeters in length and two in diameter - cylindrical or spherical pellets. Today in Russia the production of fuel pellets and briquettes is economically profitable only for large volumes.

However, to use pellets, special boiler equipment is required, the installation of which requires significant costs, while husk fuel briquettes can be burned in already installed boiler houses.

According to research by AgroSib-Razdolye, in comparison with traditional hydrocarbon raw materials, husk fuel briquettes have a number of undeniable advantages: unlike firewood, fuel briquettes have a stable moisture content of 8-10 percent, while the moisture content of firewood can constantly change, why their thermal conductivity also changes. The optimum moisture content of firewood for the firebox is about 20-25 percent, but then their thermal conductivity is 30-35 percent less than that of briquettes. "Often the supplied firewood has a moisture content of 30-40 percent, in which case the calorific value of briquettes can be 40-100% higher. That is, to produce the same amount of heat, 100 kg of briquettes from 130 to 200 kilograms of firewood will be required," they explain at AgroSib-Razdolye. The amount of heat released during the combustion of briquettes is comparable to the heat transfer during the combustion of coal, but at the same time, the ash content of briquettes is much lower - only 2.8 percent versus 10–20 percent for coal and 5–10 percent for wood. “That is, 5-10 times less combustion products are formed. In addition, the products of coal combustion contain many harmful substances and require mandatory disposal - removal to ash dumps and so on. The ash formed as a result of the combustion of husk is absolutely harmless and can be used as fertilizer ”, - Yevgenia Vasilyeva clarifies.

Other advantages are savings on transportation, savings in the space they occupy, but most importantly, environmental friendliness. According to Vasilyeva, synthetic adhesives are not used in the manufacture of briquettes. “At high pressure and temperature, a sticky substance, lignin, is released from the fibers, which binds the husk into a briquette. Due to the extremely low content of such elements as sulfur, nitrogen, chlorine in the husk, no harmful volatile substances are formed during the combustion of fuel briquettes, ”explains the marketing analyst.

The cost of briquettes - from 1,900 rubles per ton without transport delivery, the price depends on the type of packaging, the volume of purchase and other factors. According to manufacturers, this is a fairly competitive price compared to the price of firewood. “In Barnaul, the average price of birch firewood is now 1,300 rubles per cubic meter. If we translate this into kilograms and thermal conductivity, then the combustion of briquettes is 50-60 percent more profitable in terms of price. The price of coal for boiler houses is about the same, but for the population, coal will also cost significantly more, ”the company explains.

The company plans to sell briquettes in the Altai Territory and in the nearest regions. AgroSib-Razdolye fears that longer logistics will lead to an unprofitable rise in the price of the product. The company intends to sell biofuel through its Barnaul distributor.

D.Sc. N. D. Chichirova, Professor, Director of the Institute of Heat Power Engineering, Head. Department of Thermal Power Plants,

Doctor of Chemical Sciences A.A. Chichirov, professor, head. Department of Chemistry,

S.S. Paimin, post-graduate student of the Department of Thermal Power Plants, FSBEI HPE "KSPEU", Kazan;

Ph.D. A.G. Korolev, Head of the Production and Technical Department, JSC "TGC-16", Kazan;

Ph.D. T.F. Vafin, engineer, JSC "Generating Company", Kazan

Introduction

Among the most significant areas of strategic development of most domestic TPPs are developments that allow minimizing the amount of wastewater discharges generated in the technological process of heat and electric energy production by creating low-waste and non-waste water use schemes, as well as improving many existing technical and economic solutions for processing water.

The implementation of the concept of creating an environmentally friendly TPP is possible in two directions.

The first direction is based on the development and implementation of economical and ecologically perfect technologies for the preparation of additional water for steam generators and make-up water for the heating system. In this aspect, the development of effective technological schemes for water treatment at TPPs with the preservation of the basic equipment is the most promising direction that meets the requirements, especially when it comes to the expansion and reconstruction of operating installations.

The second direction is associated with the development and implementation of technologies for the most complete processing and utilization of the generated wastewater with the receipt and reuse of the initial chemical reagents in the station's cycle.

Let us consider the results that were achieved due to the implementation of a set of measures to improve the technology of water treatment at Kazan CHPP-3.

Reconstruction of a chemical desalination unit

Built according to the project of the 1960s, which did not provide for closed drainage or low-drainage and environmentally friendly schemes. With an annual consumption of 9.5 to 11.5 million tons of industrial water, according to the project, up to 4-5 million tons of saline wastewater were discharged after their neutralization through the industrial storm sewer system in the river. Kazanka and further to the Volga.

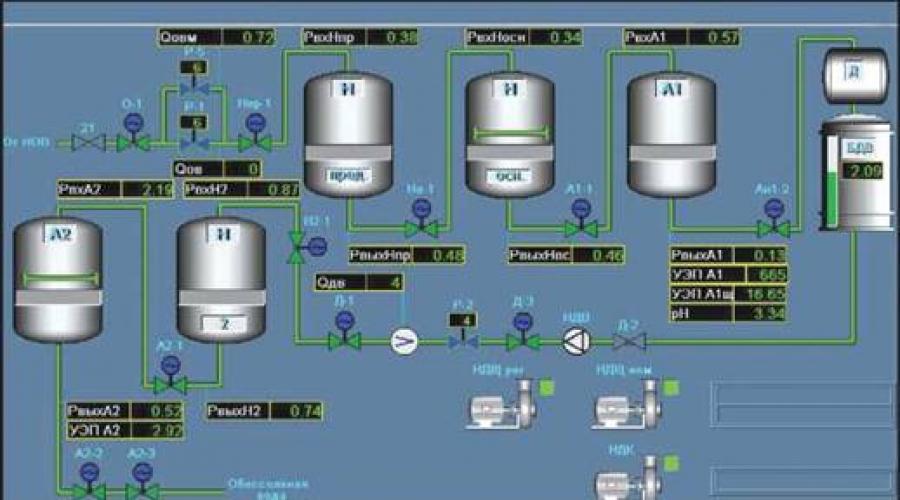

A schematic diagram of water treatment implemented at Kazan CHPP-3 is shown in Fig. 1.

The water treatment system receives the components contained in the purge water of the recycle cooling system, as well as reagents: iron sulfate, lime, sulfuric acid, sodium hydroxide and sodium chloride. In the process of liming and coagulation of water in clarifiers, some of these components are removed from the system in the form of sludge containing calcium carbonate, magnesium and iron hydroxides, silicic acid and organic compounds. In addition, some of the components are removed with the make-up water of the heating system.

The main task of the activities carried out at the station was the maximum reduction in the amount of reagents used, treatment and disposal of waste water.

In 2001, a new environmentally friendly and resource-saving technology of chemical water desalination was introduced at Kazan CHPP-3. This technology was developed at the Azerbaijan Civil Engineering University in relation to the conditions of Kazan CHP-3, taking into account the requirements for environmental protection and rational use of natural resources.

According to the new technology, the mode of chemical desalination of lime-coagulated water at the installation has changed, as well as the regeneration technology both in H- and OH-ion exchange filters (Fig. 2).

Rice. 2. Chain of filters for chemical desalination:

NOV - pumps for purified water; H pre, H main - preliminary and main H-cation exchange filter; А 1, А 2 - anion exchange filters of the first and second stages; H 2 - H-cation exchange filter of the second stage; D - calciner; BDV - decarbonized water tank.

The change in the chemical desalination regime provided for the preliminary softening of the demineralized water in the upstream H-cation exchange filter. To convert the cation exchanger in this filter to the Na-form, concentrated portions of the spent regeneration solution of H- and OH-filters were used.

Improvement in the economic and environmental performance of ionization was achieved by the use of double-flow-countercurrent ion exchange filter regeneration technology.

To implement this technology, the regeneration scheme of the chemical desalination chain No. 5 was reconstructed with the installation in the H main -, H 2 - and A 2 - filters of the middle switchgear.

The essence of the regeneration of anion exchange filters "chain" is as follows. The alkali regeneration solution supplied to the anion exchange filter of the second stage is divided into two streams. One of the streams is fed from the top, the other from the bottom. The spent alkali solution after the anion exchange filter of the first stage is collected in the alkaline water tank for reuse in subsequent regenerations.

Regeneration of H main - and H 2 - filters of the "chain" is carried out separately, independently of each other, using double-flow-counterflow technology. The acid regeneration solution is passed completely through the lower parts of these filters from bottom to top. The regeneration of the upper part of the cation exchanger, located above the middle distribution device, in these filters is carried out with the spent acid solution from the acid water tank.

Economic efficiency is achieved by saving chemical reagents used for filter regeneration, reducing water consumption for own needs of chemical water treatment, reducing the cost of preparing lime-coagulated water, reducing the consumption of raw Volga water and the volume of waste water.

As a result of the introduction of a new technology for the chemical desalination of water, the following data were obtained:

■ water consumption for own needs decreased from 36.3 to 26.4%;

■ specific consumption of acid for regeneration of H-filters decreased by 3.5 g / g-eq and amounted to 123.4 g / g-eq;

■ the specific consumption of alkali for the regeneration of OH filters decreased by 10.6 g / g-eq and amounted to 63.2 g / g-eq;

■ a decrease in the consumption of lime and coagulant in the clarifier as a result of a decrease in the consumption of demineralized water for own needs amounted to 64.2 and 25.7 tons, respectively.

At the same time, the production of demineralized water did not change significantly, remaining on average at the level of 2.8-3 million tons / year.

Introduction of the thermal desalination method

In parallel with the ongoing work on the reconstruction of the chemical desalination unit, the technology for the preparation of desalinated water by the method of thermal desalination was introduced.

In accordance with the project carried out in the 1980s, two six-stage evaporation units equipped with I-600 evaporators were built at the station. The design capacity of each unit is 100 t / h. In the late 1990s, these plants were put into operation. However, the design capacity was not achieved due to the excess steam of the last stages of the installation, which could not be fully used in the technological scheme, because the installation itself was mounted in a separate building, remote from the main technological equipment using a pair of such parameters. As a result, in the summer and transitional periods of time, the evaporators were stopped or put into operation with the release of excess steam (up to 10 t / h) into the atmosphere. Such operation of the units had a negative impact on the technical and economic indicators of the evaporators, and in 2000 it was decided to build a thermal desalting complex with a capacity of 300-350 t / h on the basis of the existing evaporator unit. The complex includes two existing six-stage evaporation plants, two flash-boiling evaporators of the IMV-50 type with deep-vacuum multi-chamber deaerators.

The IMV uses excess vapor of evaporation plants (up to 6 t / h for each evaporator), while in total up to 100 t / h of distillate is additionally produced from two IMV. The developed IMVs are fully adapted to the conditions of the complex.

These solutions made it possible to ensure the optimal use of steam of different pressures in the thermal circuit of the complex. For example, the initial steam of production extraction with a pressure of 13 ata is used as a heating for the first evaporator I-600, excess steam of a multistage evaporator with a pressure of 1.2 ata is used for an IMV, and the steam of the last stage of an IMV with a pressure of 0.12 ata is used in a vacuum deaerator.

When improving the complex, aimed at increasing its efficiency and reliability by improving the heat recovery system of evaporation plants, steam-water and jet-bubbling heaters were additionally included in the existing scheme. This made it possible to increase the temperature of the distillate and, as a result, to reduce the specific consumption of heat energy for its production (Fig. 3). This indicator is the most important characteristic of the economic efficiency of a thermal desalination plant.

At present, the production of distillate covers almost 50% of the station's demand for demineralized water.

Providing the required standards for the quality of water used to feed boilers with a superheated steam pressure of 140 ata, the thermal desalination technology has significantly lower values of water consumption for auxiliary needs in comparison with chemical methods (9 and 28%, respectively).

Economic efficiency when replacing the traditional chemical method of water treatment with a thermal one is also achieved by reducing the consumption of chemical reagents.

It should be noted that in the period under review, by analogy with the reconstruction of the chemical desalination chain No. 5, work was carried out to improve the technical and economic indicators of chains No. 6 and No. 7.

Due to the reconstruction of chains No. 6 and No. 7 and the automation of the technological process, it was possible to further reduce the values of specific consumption of acid (from 110.6 to 91.9 g / g-eq) and alkali (from 62.7 to

60.4 g / g-eq).

Utilization of waste water from a water treatment plant

The experience of creating low-waste water treatment complexes shows that the bulk of the calcium and magnesium contained in the wastewater can be removed in the form of solid sediments suitable for subsequent use, or long-term safe storage. As a result, mainly sodium compounds remain in wastewater, primarily its sulfates and chlorides. In this regard, when developing a wastewater disposal scheme for the water treatment plant at Kazan CHPP-3, the concept of maximum use of sodium salts contained in wastewater was adopted, which made it possible to reduce the cost of imported sodium chloride.

It should also be borne in mind that the amount and composition of wastewater from a water treatment plant depends on its performance, the composition of the source water and the specific consumption of reagents for regeneration. It is during chemical desalination that the main amount of sodium in the form of NaOH and sulfates in the form of sulfuric acid is introduced into the water treatment plant system. In this case, the main problem is caustic soda. In this regard, when optimizing the operating mode of a chemical desalination unit, maximum attention is paid to reducing the consumption of caustic soda. An excess of sulfuric acid is less dangerous because during neutralization with lime, the main part of sulfates is removed in the sediment in the form of gypsum.

During the operation of the wastewater disposal plant in winter, about 6.1 tons / day are generated. gypsum sludge (at 30% humidity). In the summer, the amount of wet sludge decreases to 2.7 tons / day. About 1600 tons of wet or 1200 tons of dry sludge are formed annually. The main component of the sludge is gypsum - 90-95%. The content of magnesium hydroxide is 4-5%, calcium carbonate - 1.52%. This slurry can be used to obtain high quality gypsum binder and other purposes.

When determining the economic effect from the introduction of a wastewater disposal plant, the reduction of fees for the amount of raw water used and wastewater discharge was taken into account.

With constant production, the technologies introduced at the station made it possible to achieve a significant reduction in the consumption of industrial water from 11330 thousand m3 in 2003 to 6958 thousand m3 in 2009. It is important that during the period under review, the cost of source water increased 11 times.

Along with a decrease in water consumption, it was possible to achieve a decrease in the discharge of industrial wastewater (Fig. 4), the main share of which is wastewater from the chemical department. The use of modern methods of water treatment made it possible to significantly reduce the mass of pollutants in wastewater (Fig. 5). Due to the decrease in the discharge of pollutants, the payment for this discharge also decreased (Fig. 6).

Technologies based on electromembrane devices

The purge water of the evaporation plant contains all the sodium that came with the source water and was introduced with sodium hydroxide during the regeneration of the filters of the chemical desalting plant, the chlorides introduced with the source water, as well as a small part of the sulfates introduced with the source water, coagulant and sulfuric acid during the regeneration of the filters.

Attention should be paid to the high content of alkali and alkaline components (sodium carbonate) in the purge. Alkali and soda are expensive products that are widely used in water treatment plants of thermal power plants. Note also the almost complete absence of hardness ions. In this connection, the idea of dividing the blowdown water into alkaline and softened solutions and their use in the station cycle was formulated.

To utilize excess blowdown water from evaporators, a technology has been developed using electromembrane devices (EMA) as the main element (Fig. 7).

At the first stage, the alkali is partially separated from the initial solution in EMA with cation- and anion-exchange membranes. Since the selectivity of the process is low, it is possible to obtain an alkaline solution containing the salts of the initial solution as a product.

EMA of the first stage produces a concentrated alkaline solution and diluate-1. The latter is a more dilute solution of the initial salts and the remaining alkali. Diluat-1 is the starting solution for the second stage EMA.

EMA of the second stage is assembled with bipolar membranes and serves to separate the salt solution into alkaline and acidic solutions. As products at the second stage, diluate-2 is formed, which is a more dilute solution of the initial salts, non-concentrated solutions of alkali and a mixture of acids.

Diluat-2 is sent to the EMA of the third stage, the alkaline solution - for concentration in the first stage or to the EMA alkali concentrator. An acidic solution containing a mixture of sulfuric, hydrochloric and nitric acids is sent to the consumer.

At the third stage EMA, the process of concentration-desalting of diluate-2 is carried out to obtain partially demineralized water with a salt concentration of about 0.3 g / l (diluate-3) and a concentrate.

The scheme (Fig. 7) uses three devices with a total power consumption of 100 kWh per 1 ton of the treated solution. As a result of processing, 0.4 tons of an alkaline solution (5% alkali, 1% salts) and 0.6 tons of an acidic solution (1.2% acids, 1% salts) are formed. The presented scheme is flexible enough. A sequential reduction of steps is possible, starting with the last one.

If the third stage of EMA is removed, partially demineralized water for the second stage can be taken from the TPP TLU. An equivalent amount of water in the form of diluate-2 (sodium salt solution) is sent to feed the heating network. Thus, there is an exchange of water between the water treatment and electromembrane installations.

With the reduction of the third and second stages at the same time, on the EMA of the first stage, it is possible to obtain an alkaline solution and diluate-1. The alkaline solution is sent for concentration or directly to the consumer. Diluat-1 (brine) can be used to regenerate Na-cation exchange filters, to feed a heating system or to feed evaporators.

In the diagram in fig. 8, two EMAs are used with a total power consumption of 13 kWh per 1 ton of the treated solution. In this case, the products of processing the blowdown water of the evaporators are 0.1 ton of an alkaline solution (4% alkali, 2% salts) and 1 ton of brine (2.5% initial salts).

The relatively low operating costs make the most appropriate use of the scheme shown in Fig. 8, for the disposal of the blowdown water of the evaporators to obtain concentrated alkaline and softened salt solutions, which are used in the technological cycle of the station.

conclusions

1. At Kazan CHPP-3, a new technology for processing liquid waste from a water treatment plant was introduced with the production and reuse of softened salt and alkaline solutions in the station's cycle.

2. A closed cycle has been created, which ensures the drainlessness of the TPP water treatment technology.

3. The research results, as well as the developed schemes, can be used in the creation of low-waste water use complexes both at existing TPPs and other industries in the process of their reconstruction, and during the construction of new ones.

Literature

1. Abramov A.I., Elizarov D.P., Remezov A.N. and other Improving the environmental safety of thermal power plants: Textbook. textbook for universities / Ed. A.S. Sedlova. Moscow: MEI Publishing House, 2001.378 p.

2. Larin B.M., Bushuev E.N., Bushueva N.V. Technological and environmental improvement of water treatment plants at TPPs // Teploenergetika. 2001. No. 8. S. 23-27.

3. Chichirova N.D., Chichirov A.A., Korolev A.G., Vafin T.F. Environmental and economic efficiency of introducing resource-saving technologies at thermal power plants // Trudy Akademenergo. 2010. No. 3. S. 65-71.

4. Sedlov A.S., Shishchenko V.V., Fedoseev B.S., Potapkina E.N. The choice of the optimal method of water treatment for thermal power plants // Teploenergetika. 2005. No.

5. Sedlov A.S., Shishchenko V.V., Fardiev I.Sh., Zakirov I.A. Integrated low-waste resource-saving technology for water treatment at Kazan CHPP-3 // Teploenergetika. 2004. No. 12. S. 19-22.

6. Fardiev I.Sh., Zakirov I.A., Silov I.Yu., Galiev I.I., Korolev A.G., Shishchenko V.V., Sedlov A.S., Ilyina I.P., Sidorova S.V., Khaziakhmetova F.R. Experience of creating an integrated low-waste water use system at the Kazan CHPP-3 // New in the Russian electric power industry. 2009. No. 3. S. 30-37.

7. Feyziev GK Highly effective methods of softening, desalination and desalination of water. M .: Energoizdat, 1988.

8. Feyziev G.K., Kuliev A.M., Jalilov M.F., Safiev E.A. Ways of creating highly efficient schemes for drainless water desalination by chemical methods // Chemistry and technology of water. 1984. No. 1. S. 68-71.

9. Sedlov A.S., Shishchenko V.V., Ilyina I.P., Potapkina E.N., Sidorova S.V. Industrial development and unification of low-waste technology of thermochemical softening and desalination of water // Teploenergetika. 2001. No. 8. S. 28-33.

10. Khaziakhmetova D.R., Shishchenko V.V. Treatment and utilization of saline waste water from chemical desalting plants // Teploenergetika. 2004. No. 11. S. 66-70.

11. Sedlov A.S., Shishchenko V.V., Sidorova S.V., Ilyina I.P., Laryushkin N.I., Egorov S.A. Experience in the development of low-waste water treatment technology at the Saransk CHPP-2 // Electric stations. 2000. No. 4. S. 33-37.

12. Chichirova N.D., Chichirov A.A., Lyapin A.I., Korolev A.G., Vafin T.F. Development and creation of thermal power plants with high environmental performance // Proceedings of Academenergo. 2010. No. 1. S. 34-44.

13. Chichirova N.D. Electromembrane technologies in power engineering: monograph / N.D. Chichirova, A.A. Chichirov, T.F. Wafin. - Kazan: Kazan. state energ. un-t, 2012.260 p.

14. Vafin T.F., Korolev A.G., Chichirova N.D., Chichirov A.A. Implementation of electromembrane technology for wastewater treatment at Kazan CHPP-3 // Proceedings of the VII School-Seminar for Young Scientists and Specialists under the leadership of Academician V.E. Alemasov. Kazan. 2010.S. 434-436.

15. Patent for a useful model of the Russian Federation No. 121500. Installation for processing industrial waste water and obtaining a concentrated alkaline solution and softened saline solution / T.F. Vafin, A.A. Chichirov. Publ. 27.10.2012, Bul. No. 30.

16. Vafin T.F., Korolev A.G. Electrodialysis plant for wastewater utilization of TPP TPP and generation of alkali // Materials of reports of the V International youth scientific conference "Tinchurin readings". Kazan, KSPEU. 2010. Vol.2. S. 167-168.

17. Chichirova N.D., Chichirov A.A., Vafin T.F., Lyapin A.I. Technical and economic assessment of the efficiency of using electromembrane technologies at domestic thermal power plants // News of higher educational institutions. Energy problems. 2013. No. 3-4. S. 14-25.

In matters of impact on the ecosystem, economy and society, the foremost actors are environmental degradation and climate change. According to the UN, by 2030 the world's population will reach eight and a half billion people. And by the middle of the century, more than half of the world's population will live in cities. This means that if the environment is not adapted to the growing population, the ecological conditions of living in megacities will continue to deteriorate rapidly.

Photo: pixabay / diegoxueWhat to do about it? Researchers from the Blekinge Institute of Technology in the Swedish city of Karlskrona are confident of introducing and developing a circular economy in cities. They released the report The Cyclical Economy: Experiences from Cities Around the World, which analyzed various urban projects related to the cyclical economic model. The experts covered 21 cities in the USA, England, the Netherlands, Sweden and other countries. The researchers described projects that were financially supported by municipalities and how these initiatives have benefited the city.

Circular economy is an approach in which everything that was previously considered unnecessary is returned to production and sent to landfill within the framework of following the linear economic model "produced - consumed - thrown away." Experts from the Blekinge Institute of Technology noted which departments of the city administration were involved in the implementation of the initiatives, and what benefits such projects ultimately bring to cities and their residents.

From waste to the right things

The city government is able to regulate the waste situation in the city and use the market for its beneficial use. For example, the researchers noted in the report the successful project of the ReTuna shopping center in Sweden, where all products in stores are used items and residual materials. Residents leave various second-hand items in the mall. The staff of the center, if necessary, repair them and sort them into departments. Each store is owned by independent entrepreneurs. In 2016, ReTuna provided jobs for 47 residents of Eskilstun.

Photo: lm-magazine.com

Technology is the head

An example of the introduction of new technological solutions for the transition from linear economic models to closed cycles can serve as a project for the extraction of biogas and fertilizers from organic waste in Oslo. To this end, the municipality has invested in the construction of an urban biogas plant. The generated gas is used to refuel garbage trucks and public buses. And the municipality transfers the by-products of production to local farmers as biofertilizers.

Inspire with resilience

As an example of interaction between city authorities and businesses, the report cites the 20 | 20 business park in Haarlemmermeer, in the west of the Netherlands. The park is built in accordance with Cradle to Cradle (C2C) standards, which means "From cradle to cradle" in English. This concept is based on the idea of cyclical zero-waste production systems that do not harm the environment. The park occupies 92 thousand square meters of area, which houses offices, supermarkets, a fitness center and several restaurants. All projects have been implemented with an emphasis on reducing CO2 emissions and introducing the principles of a cyclical economy.

Photo: i.ytimg.com

Share your raw materials

The study authors note that municipalities can play a role of helpers in environmental interactions between city companies. For example, Peterborough City Council funded the creation of the Share Peterborough online platform, where firms can trade and exchange various resources among themselves. And not only materials, but also conference rooms and even skills. The main condition is to use everything as much as possible so that the word "unnecessary garbage" disappears from the everyday life of doing business in the city. At the heart of such an initiative is the promotion of “business to business” or B2B ideas, which means “business to business”. B2B means that a company works not only for the end consumer, but also for other companies.

In Russian reality, initiatives towards closed production cycles often move from the bottom up - from business initiatives to municipalities. For example, in order to promote the development of a cyclical economy in Russia, the supplier of packaging, stationery and household goods for business "Opticom" launched a project for the disposal of paper waste "Bumagovorot". At the center of the project are metropolitan offices, where paper most often turns into useless rubbish. However, collecting waste paper means both caring for forests (recycling one ton of paper saves 24 trees), and reducing CO2 emissions into the atmosphere, as well as significant savings in water and energy. The idea of "Opticom" in some way intersects with the initiative in the city of Peterborough, pursuing the principles of the most efficient use of resources and the principles of B2B service.

“Paperwork is in line with our mission to help build a cyclical economy in Russia. We collect waste paper, which is then used to produce paper packaging, thus closing the cycle. This not only prevents the growth of landfills, but also helps to conserve natural resources, ”says the general director of the company Maksim Rogozhko. So far, the project is being implemented only in Moscow and involves the purchase of consumables by a partner company from Opticom.

At the same time, the company offers green offices a line of environmentally friendly products: from paper hygiene products made from recycled fibers to biodegradable detergents. In order for office staff to quickly adapt to the collection of waste paper, the company provides free trainings for the personnel of the companies participating in the project. During the briefing, employees receive information on how and why to collect waste paper separately from household waste, what types of paper Opticom accepts for recycling and why cardboard cups cannot be placed in a waste paper container (hint: such cups are not recycled in Russia yet).

Once Walter Stachel gave the world the expression "from cradle to cradle", meaning a closed cycle. Today this Swiss analyst is considered one of the foremost experts in cyclical economics.

- Tell us about the circular economy model, or, in other words, the cradle-to-cradle principle.

In the 1970s, landfills were the main way to dispose of waste. The discussion of this issue spawned the concept of "from cradle to grave" and revolved around improving the quality of "graves" for rubbish, which, in my opinion, could not be called progress. In response, I began to use the term “cradle to cradle”, emphasizing that “graves” are a last resort.

I prefer the terms “circular economy” or “cyclical economy” to the term “cradle to cradle” because they use the word “economy”. By examining the economic side of the issue, we immediately understand that even the smallest cycles - reuse, refurbishment, modernization and re-marketing of goods and components in the industry - bring great financial benefits. The reason for this is the minimum cost for the buyer and the maximum profit for the manufacturer.

When studying economic indicators, it is necessary to simultaneously consider what exactly will bring the maximum profit. For example, when developing new products, it is important to know the actual or equivalent water content of the feedstock.

While time consuming, small cycles provide great social benefits. Consuming a very small amount of raw materials and energy resources, and having a local character, they increase the level of local employment and, thereby, stimulate the economy of the respective regions. In the context of sustainable development, we are constantly working to optimize these three factors: economic, environmental and social.

There are areas where the circular economy has been used for many years, and we may not even be aware of those phenomena of our world that already meet its criteria. Take, for example, the concepts of reuse, re-marketing of goods and components, or refurbishment. The clearest example of their successful application is eBay and any other national or regional site through which used goods are sold by a consumer to a consumer (c2c) or a commercial company to a consumer (b2c). While there were flea markets or second-hand clothing stores before eBay, what we have today is a huge global re-marketing platform. Essentially what we are trying to achieve in the circular economy model.

EBay's goal is to sell products at the best possible price. In other words, the main goal of the circular economy business model is profitability, and the goal is the result. This involves rethinking the idea of buying and selling goods as services rather than products and turns buying and selling into results.

Although the business model of renting goods has always existed within the industrial economy, in the circular economy it has encompassed a much wider range of goods. If we can rent a car, apartment or office, why not rent clothes? Renting clothing for special occasions has become commonplace, but why not rent other types of clothing as well? Handbag rental is still developing, and the rental of tools and equipment for construction sites has become commonplace. At almost any airport, consumers can rent computers and mobile phones.

The circular economy also favors the collective consumption of goods as services, as can be seen in public transport, including railways, aviation, metro, municipal bicycles and taxis, and toll roads, bridges and tunnels. In all these operations, you get the result. Along with acquiring the right to use an item, you gain confidence in the guaranteed result and that the life cycle of that item has been properly managed.

One of the most recent areas to be covered by the purchase of the result is electronic goods. We all use the Internet, smartphones, cloud services, e-banking and the like, forgetting that satellites are used to make them work. Even the simplest ATM withdrawals when you are abroad use the cloud, the Internet and satellites. Today, GPS is used in almost every industry, from aviation and logistics, cargo transportation and oil production to our cars. In all these cases, we purchase the service without any responsibility for the content of the product. We just enjoy the result.

The result economy uses the principles of a circular economy until we stop buying goods and just switch to services. To a certain extent, we, as consumers, businessmen and even politicians, have already entered this new economy.

- What do you think about the return of materials in the context of the reuse or destruction of toxic substances?

Retaining ownership of the product encourages the company to move away from the use of toxic substances in the product. If their use cannot be avoided, it will take steps to simplify the process of their extraction and separation and will make great efforts to prevent the opposite. This is especially true for high-value substances such as rare earths used in non-recyclable electrical and digital products.

- Why do you think that the circular economy has not become widespread?

Only because the problems we have discussed are mainly inherent in the industrialized countries of Europe and North America. Developing countries face very different challenges related to scarcity of resources, skilled labor, goods and food. In the face of scarcity, the best strategy for raising the standard of living of the population turns out to be mass production of inexpensive goods.

Countries with economies in transition, for example, China, having formed infrastructure, stocks of goods and a system of public services, can engage in their maintenance, proper operation and maintenance. For poor and under-resourced African countries, circular economies are useless in their environment. Before they can begin to stockpile goods and develop infrastructure that they can maintain and store, they need to achieve some level of well-being.

The circular economy will never be a global model. She has already come to developing countries, but only because of their poverty. The populations of these countries are forced to restore and completely modernize their products, but this is done at a low technological level. The reuse of goods in these countries is accompanied by high levels of pollution. In African and Asian recycling plants, electronic devices are burned to extract rare earth elements. So it turns out that many of the less developed countries are already applying the principles of circular economy, but ironically, in doing so, they damage the environment and the health of their citizens.

The traditional, linear concept of an industrial economy still has many advantages in the eyes of economic operators, and one of them is the possibility of externalizing the cost of risk and production waste. If you can pass this cost onto the government or consumers, your profits will increase, you will get more money.

In the long term, political stability must be considered. For example, in the Sahara Desert, an environmental project called DESERTEC is being implemented. This is a huge solar panel that will generate electricity to supply countries in Europe. The project has been implemented for about five years and is supported by large European companies. If you look at the current state of the Sahara, it might seem that investing billions in a region controlled by al-Qaeda is sheer madness. I think that if you want to help Africa or many other countries, then you need to provide them with such help that will allow them to help themselves, but in no case should you try to do this work for them.

- What are the main obstacles at the state level do you see and how to overcome them?

They are mainly related to the existing economic model. Politicians mostly live in an industrialized economy. In other words, if they want to create new jobs or take measures to develop the economy, all they can understand is programs like Cash for Clunkers. They want to send cars over eight or nine years old to the junkyard and force people to buy new ones. At the same time, they completely ignore the alternative option, which consists in a complete modernization of the engines, and in fact the environmental characteristics are determined mainly by them. A complete engine upgrade may cost the same as the Junk Cash Program, but save 80% of the vehicle investment.

In my opinion, the most significant thing that politicians can do is change the tax system. The introduction of a system of socially responsible taxation, that is, taxation of non-renewable resources (energy and raw materials) and exemption from taxes of renewable ones, which include human labor, would be a huge stimulus for the development of a circular economy.

The second important aspect of socially responsible taxation can be the application of value added tax only in relation to transactions in the course of which added value is actually generated. Since this does not happen in the case of transactions carried out within the framework of a closed-cycle economy, the use of VAT is out of the question. This concept was adopted in principle by the British Treasury and a number of other European countries (in particular, the Scandinavian ones), where a VAT of 25% is applied. Avoiding VAT on refurbishment, full modernization, or re-marketing of goods will show the business community the benefits of being socially responsible in a circular economy.

Income tax was invented in Europe and was intended to finance military action. In France, these were the Napoleonic Wars and the First World War. At the end of hostilities, the tax was not canceled.

There is no payroll tax in China, Russia, India and a number of other countries. 11 states of the United States do not apply income tax, and another 12 are talking about waiving it. So how do the governments of these entities get their income? In Texas, for example, taxes are levied on oil production. In Florida, the situation is similar: construction is levied there. Half of government revenues to the Russian budget come from the production and sale of oil and gas.

States should tax what they want to restrict and exempt what they want to stimulate, such as labor. Of course, each country should independently regulate taxation issues, based on its own priorities.

- How can businesses stimulate a circular economy?

Developing business models for returning or re-marketing your own products is the most a business community willing to participate in promoting the circular economy can do. To do this, it is necessary to develop products taking into account their full life cycle and using a modular concept based on standardized components, giving preference to system solutions rather than isolated solutions.

It's very simple: if a company does not want its products back, it cannot profit from them at the end of their useful life. If developing sustainable products increases costs and generates too little profit, then there is little incentive to do so. Why produce smart goods when someone else will profit from them? If the company starts selling the result of using its products, while retaining ownership of them, and, consequently, the resources invested in them, then its future income can increase significantly.

Throughout the 20th century, commodity prices have been steadily declining. Since 2000, they began to grow, and today they have reached a level comparable to 1900. Obviously, retaining ownership of materials and resources is pointless if the new product is cheaper than the one purchased ten years ago.

This approach is justified when commodity prices rise, because, in a nutshell, today's goods are tomorrow's resources, sold at yesterday's prices.

By starting to sell the result instead of goods and retaining ownership through the use of lease or leasing, the company is guaranteed that in five or ten years it will have all the necessary resources to produce new goods.

In addition, instead of starting a cycle for processing components or goods as a whole, the company can engage in their complete modernization. If ownership is retained, this decision remains with the individual manufacturers. Only they can decide on the most beneficial option for them at the end of the product's useful life.

- In some industries it is relatively easy to switch to leasing or leasing, in others such a transition will require significant capital investments to launch new processes. How can a company determine the right moment of transition?

To be honest, I don't think now is the right time. A very good moment was five or ten years ago, when companies were actively growing, and because of this, the market did not so insistently demand from them to apply innovative solutions. In fact, if you decide to change your corporate strategy, every moment is right.

Sustainability is easy for players in the rental property market, as long as they provide adequate insulation and high energy efficiency of the proposed buildings. Taking into account schools, subsidized housing and government agencies, the share of public buildings in the general stock grows significantly. Bringing these buildings to modern thermal insulation standards is very laborious, but at the same time practically does not require expenditures on energy resources and materials. If the cost of labor were lower, for example, through tax exemptions, then costs could be significantly reduced.

In the long term, the benefit lies in a large reduction in energy costs for heating or cooling these buildings. This refers to one of the mysteries that most governments have not solved - the Kyoto Protocol. Government circles have asked us for clarification on the possibilities of significantly reducing carbon dioxide or greenhouse gas emissions while creating new jobs in the local market. I think that if construction companies were to embrace this whole business model and start demanding support from governments, then it would be extremely difficult for the latter to declare that they cannot afford it.

The main issue is incentives. The fact is that instead of modernizing buildings, construction companies can opt for demolition and new construction, because this is their job. At the same time, the reconstruction and technological modernization of existing buildings requires little time, money and, by and large, provide much better energy efficiency.

- What are the main difficulties companies may face in the transition to a circular economy model?

Let's take a look at this question using the example of the carpet company Interface. Ray Anderson, CEO of the company, made the move and was the first to offer a 10-year carpet lease. This idea has attracted few so far. The problem lies not with the company itself, but with its customers, who may consider themselves able to manage the entire system at a much lower cost.

Budget payments, for example, are unequivocally dedicated to the provision of schools, roads, the military. Once a 20-year, binding social responsibility agreement, similar to Interface's proposal for sustainable carpets, is proposed, the Treasury faces a major hurdle because, with such an agreement, it will not be able to freely transfer funds between sectors.

Once the lease is signed, the government will have to pay a fixed amount annually. If they buy a carpet and use it for 20 years with the help of the local service industry, then at the end of this period they find themselves in a difficult financial situation (like the sequestration that took place in the United States, or the austerity regime in the EU), and therefore they accept a simple solution: don't buy a new carpet.

Such freedom of the treasury in its actions is impossible if the government receives the carpet on a long-term agreement. Usually people don't want to talk about these difficulties, but this is the very reason why many new business models simply fall apart during the marketing phase. The reason is simple: the consumer has his own problems, not related to the carpet, but he is not able to solve them.

Everything is tied to the type of activity. Michelin sells tires as a service, and jet engine manufacturers sell power by the hour. Because of the clear definition of these markets, the consumer can see the benefits in both cases. He no longer needs to think about products, because he receives them in the form of a service at a fixed price, and for him this is the best option.

Consider the automotive industry, another mass-produced market. Here, the idea of selling a product or a machine as a service contradicts what is being done today: highly efficient production within centralized, global supply chains, followed by sales through dealers.

A carmaker's intention to rent or share cars means that it needs a representative or rental office at every airport and every city, which in turn means that it can no longer make the best use of its knowledge of efficient car production.

Often, when moving from selling goods to selling services, companies are faced with a problem that is completely unfamiliar to them, do not have the necessary skills and are forced to establish new distribution and return channels. And businessmen are asking the question: "Why don't we just continue to implement the traditional business model, even though it is not socially responsible?" Or "Even if my current activity does not allow creating new jobs, saving resources or preventing waste generation, and changing the situation in the short term is not beneficial for the government or industry, why would I?"

- So why do companies need to do this?

Actually, they don't have to do it. When I gave presentations on Circular Economy in the 1990s, I often ended them with a slide that said, “You don’t have to do any of the things that have been said here. Nobody requires you to survive. " After someone told me that this slide caused depression, I stopped doing it. But it remains an argument for sustainable development. You can completely ignore all the concepts of circular economy, but if any of your competitors take advantage of them and succeed, then it turns out that your decision caused your company to leave the market.

“Today, a lot of attention is paid to reducing waste production rather than dismissing it.

I think that for reasons of profit, material costs have always been the focus of the manufacturing industry. Today's change is that from the processes associated with the consumption of materials, we will switch to the processes within which we create products, and this means that there is no production waste.

A great example of this change is 3D printers, which so far work primarily with plastics. If they can be adapted to work with metals, then there will be an era of much more material and energy efficient, waste-free manufacturing processes.

A circular economy can solve the problem of end-of-life waste. I have never been a supporter of the so-called zero-waste technologies, because in the Western world zero is a non-motivating goal. It is much better to look at the situation from the other side and replace the idea of zero waste with the idea of one hundred percent profit. Your shareholders expect you to turn a ton of materials into a ton of products that you can sell, so when you talk to any Western executive about the concept of 100% profit, they are immediately interested.

- In the UK, another approach is very popular - offsetting carbon emissions.

Today the price of carbon is around 3 euros per tonne, which tells us that this market, if it ever existed in Europe, has collapsed.

Another issue related to offsetting emissions is finding investment opportunities. Investments in social sustainability today account for only 5% of all capital investments. If you look at the large companies from which you can purchase this offset, you will see that they are investing mainly in the money markets because they simply do not see enough opportunities to invest in offsetting activities.

Yes, the idea was interesting, but it meant that companies could try to hide their carbon footprint. In fact, and I've talked about this before, either you do it for yourself or you find another solution. Attracting external resources will not help solve this problem.

You can reduce your carbon dioxide emissions by switching from coal or oil to natural gas. The shale revolution we are seeing in the United States is only happening because any form of natural gas, be it methane or biogas, has more hydrogen molecules and less carbon, resulting in less carbon dioxide emissions and more water production. Thus, you will reduce not only carbon dioxide emissions, but also all greenhouse gases, including nitrogen and sulfur oxides, by about 80%. But this does not increase energy efficiency!

Therefore, taking care of stocks and optimal ways of using them, we refuse to solve our problems by producing more goods (at least in industrialized countries), and at the same time our economy is one step closer to the model of a closed cycle, and society benefits from the creation of jobs in the regions, the reduction of waste generation and a significant reduction in resource consumption.

“We can still provide ourselves with wholesome and healthy food. But as long as the concept of profit exists, your task as a biological organism is simply to survive " Anatoly Kokhan

At the dawn of its formation, modern civilization can provide itself with safe and healthy food. Closed ecological agricultural cycles can provide environmentally friendly and healthy food.

Take a plot for your personal subsidiary farm and try at least sometimes to eat yourself and treat your relatives with an environmentally friendly product that cannot be bought, neither in the market, nor in a store, and for any money.

The basis of a closed agricultural cycle is the balanced maintenance of farm animals and the cultivation of crops on a limited land plot as a quasi-closed ecosystem, part of which is a consumer, a person who is physically removed from it.

Thus, we get a self-renewable resource of consumption in the form of an environmentally friendly, high-grade agricultural product.

Closed ecological agricultural cycles will make it possible to solve the issue of production of ecologically clean, nutritious and healthy products in terms of maintaining immunity during the development of technologies for the production of high-grade mineral nutrition, if the use of mineral nutrition shows its appropriateness.

Closed ecological agricultural cycles exclude the use of mineral fertilizers, growth stimulants, herbicides and similar agricultural technologies.  Bacteriological and anti-infectious measures are carried out as needed. Closed ecological agricultural cycles are localized in a limited area, where a certain bacteriological regime is maintained, the composition of microflora and fauna, which does not contribute to, but prevents the development of dangerous infections.

Bacteriological and anti-infectious measures are carried out as needed. Closed ecological agricultural cycles are localized in a limited area, where a certain bacteriological regime is maintained, the composition of microflora and fauna, which does not contribute to, but prevents the development of dangerous infections.

The initial testing of prototype technologies of closed ecological agricultural cycles is currently being carried out on the basis of Anatoly Kokhan's private farm.

The direction of work on the creation and improvement of closed ecological agricultural cycles must be continued and developed. To date, some significant results have already been obtained. Of course, the results and recommendations achieved should be expanded and refined, but today they can already be used in practice.

At the present stage, products obtained with the help of a closed ecological agricultural cycle are not so important as everyday nutrition, as an analogue of a drug that allows to restore the natural functions of the human body associated with the construction and restoration of tissues, metabolism, treatment and prevention of diseases that have spread to urban life, as well as a change in human nutrition.

Products of ordinary private household plots, hunting trophies and collected forest gifts cannot replace them or be their equivalent, due to uncontrolled environmental pollution. The cleanest areas are potentially and in fact places of increased pollution.

Creation of a closed ecological agricultural cycle.

To create closed ecological agricultural cycles, it is advisable to use agricultural land, however, the long-term use of herbicides led to long-term pollution, and the lack of crop rotation of agricultural crops led to land depletion. Meadow grasses, shrubs and overgrowth of agricultural land with forests, of course, cleanse the land, but they simultaneously deplete the soil and cause surface accumulation of pollutants and carcinogenic substances. Therefore, first of all, it is necessary to carry out measures to clean up any territory planned for the organization of closed ecological agricultural cycles.Initially, it is necessary to use agricultural land, traditionally suitable for various types of agricultural work.

Site preparation for the organization of a closed ecological agricultural cycle. Territory planning.

First of all, it is necessary to plan the territory of the site and start developing and cleaning it. It is necessary to take into account climatic conditions, soil characteristics, landscape features and site humidity.In this case, you must take into account not only the characteristics of the upper soil layer, but also the subsequent ones, especially the characteristics associated with moisture absorption, looseness and, of course, the chemical reaction and features of the chemical composition.

At this stage, you should already pre-plan for the type of closed ecological agricultural cycle to be used, the types of farm animals raised, poultry, crops grown, fruit trees and shrubs, and trees and shrubs used for technical and environmental purposes.

Particular attention should be paid to the landscape and the natural circulation of moisture. Your farm should make the most of the terrain and irrigation properties you may need to build.

The plot is planned in such a way that you use electricity and energy-consuming technologies to a minimum. The turnover of agricultural products must be combined with soil enrichment, environmental cleansing and renewable energy resources.

If you have a small plot for individual use, for example: one hectare or less, even if the use "for animal husbandry" is permitted, you will not be able to keep cattle on it, even one cow. This site is small. You can't even keep rams. In a closed ecological agricultural cycle, you can count on a few goats, a small number of poultry and, of course, rabbits. Perhaps the landscape will allow you to make a small pond for fish, crustaceans or molluscs. Part of the site will have to be devoted to plant growing and a vegetable garden.

You will have to use machinery anyway, so plan driveways and sanitary barriers right away.

Fruit trees and shrubs will act as sanitary barriers and snow retention. If you are using firewood, you should consider replanting fast-growing trees for your firewood. The cycle should be complete and closed, no matter what types of farm animals you breed and what kind of crop rotation you organize.

If possible, on the site you should organize the collection of water for agricultural, technological, domestic and fire-fighting purposes.

It is also necessary to plan the place of collection, sorting and disposal of waste associated with the use of technology, packaging and transportation that are not involved in the ecological renewal cycle.

Primary cleaning of the site from pollution and the launch of a closed ecological agricultural cycle.

Cleaning the site from contamination should start by looking for information about the use of the site earlier, as well as using neighboring sites and looking for potential sources of air pollution, spring and storm water and potentially dangerous objects in terms of contamination on your site. Special attention should be paid to official and actual cattle burial grounds, existing spontaneous, organized and abandoned landfills, cemeteries and spontaneous burials of infectious and chemically hazardous waste.After investigating the state of the territory and potential threats, surface debris is removed and hazardous sources of pollution are eliminated. It must be remembered that any disposal is part of the ecological cycle. For this purpose, not burial or disposal of biological and chemically hazardous materials is carried out, but their neutralization in order to ensure subsequent biological safety.

After surface cleaning, measures are taken to neutralize potential pollution threats.

Final cleaning is carried out from biologically active pollutants and herbicides and fertilizers previously used in the agricultural area. The final clean-up lasts about seven years and is combined with the restoration of the soil cover through the cultivation of crops and the keeping of farm animals.

This is the start-up period for a closed ecological agricultural cycle. During this period, the biological system makes it possible to include a person as a consumer, and the food product will surpass the quality of the products of traditional and industrial agriculture, however, the ecological system is still at the stage of entering equilibrium and freeing itself from previously accumulated pollution. It should be noted that such systems cannot be isolated from global and large territorial pollution of the current period.

The introduction of closed ecological agricultural cycles does not eliminate the problems of environmental protection and disposal of waste from industrial production, transport, extractive industries, settlements and retail chains. However, the very production of agricultural products becomes safe and ceases to be a source of environmental pollution.

Seven-year agricultural cycle of biological treatment and soil restoration.

The experiment of Anatoly Kokhan's personal subsidiary farm showed that the cycle of biological treatment was seven years. During this time, farm animals were completely transferred to full-value nutrition from the same land plot and the soil cover of the land plot received sufficient enrichment with organic matter for agricultural plants.One should not think that a closed ecological agricultural cycle is possible with the use of only fencing technology. It is not enough to build a fence and let animals in there to live and reproduce. Environmental systems are self-regulating. From such a system, it is impossible, painlessly, for the ecosystem itself, to select biological material for food for an organism that is outside the ecological system itself.

Fencing is an important detail for ensuring the sanitary regime of closed ecological agricultural cycles, however, the determining factor of functioning to ensure the selection of biological material from a closed ecological cycle (for cooking) is the management of populations of fauna and flora and the reimbursement of the waste products of a remotely served population in a closed ecological cycle ...

First of all, it is necessary to use siderates (green fertilizers). Then fodder crops in combination with the maintenance of herbivores and poultry. Plant trees in parallel. Then you move on to the planned formation of a closed ecological agricultural cycle.

While cleaning the soil, you must make yourself a complete understanding of what animals and birds you can keep and what kind of feed you will grow for this. During this period, you can experience the technologies of growing plants, animals and poultry on your own experience.

Practical organization of a closed agricultural ecological cycle.

The cultivation of vegetables, berries and fruits in a closed ecological agricultural cycle is associated with a complete rejection of chemicals that protect against pests.The fact that growth stimulants and chemicals for weed and pest control are abandoned are calling into question agricultural yield. Therefore, pest control is carried out with the help of their natural enemies. Weed control - non-industrial growing methods.

It is advisable to grow vegetables in a closed ecological agricultural cycle for human consumption, in case of excess or illiquid, they are fed to domestic animals.

Potatoes are an important crop in the human diet. However, the cultivation of potatoes is associated with the defeat of the Colorado potato beetle. In a closed ecological agricultural cycle, potato cultivation is accompanied by the maintenance of a sufficient number of adult guinea fowl - a natural enemy of the Colorado potato beetle. At the same time, the guinea fowl should be raised without the use of intensive feed and technologies used in industrial poultry farming in order to preserve its natural diet.

Cabbage is a very useful plant, but it is also highly susceptible to various kinds of pests and is loved not only by humans, but also by pets and birds. To protect cabbage from pests, small birds are used, for which an excessive number of birdhouses are installed at the growing site or special protected growing methods are used.

Tomatoes are not only susceptible to cold, but also popular with birds. With an excess population of small birds, all ripe fruits will be destroyed. Therefore, tomatoes must be covered with a non-woven fabric. In addition, tomatoes cannot be grown with a significant amount of weeds and the soil should be covered with an opaque non-woven fabric.

Cucumbers are well suited for indoor and outdoor cultivation. A light-proof non-woven fabric is used for weed control.

Zucchini, squash and pumpkins are grown in small quantities on the manure of poultry and animals, without contact with the latter, since for many of them they are a delicacy. These crops can be grown on compost heaps and pits.

Field crops are among the most important crops. Bread is the basis of the human diet. An experiment in the personal subsidiary farm of Anatoly Kokhan showed that grain grown by industrial methods causes progressive obesity in animals and poultry, while fodder grown in a closed ecological agricultural cycle allows animals to develop harmoniously and even excess consumption does not cause pronounced obesity.

When growing field crops, it is necessary to follow the rules of crop rotation and change crops in places. However, in closed ecological agricultural cycles, fertilizers and herbicides are not used. This causes weed contamination of crops, which reduces the requirements for crop rotation. In addition, grain harvesting must be carried out with the weed seeds. The presence of weed seeds in animal feed eliminates the need for additives that are vital for animals and poultry, since they receive additional necessary elements from weed seeds.

Field crops can be grown in small areas and harvested in the traditional way or with the help of small-scale mechanization.

The main field crops recommended are wheat, barley and oats. It is useful to use millet, both the grain and the harvested straw of this crop are of high value, but you must make sure that millet can actually be grown in the conditions of your strip.

Grain storage encourages rodent reproduction, while keeping farm animals and birds will attract wild predators to you. Therefore, there should be dogs and cats on your site. These outdoor pets are healthy and solve problems with rodents and wild animals. Do not use hunting dogs, you will lose your livestock.

It is advisable to grow alfalfa from forage grasses, it enriches the soil well and is a valuable forage crop not only for herbivores, but also for almost all birds. But alfalfa is not the only one available; clover, herbal mixtures, or other herbs can be used. In closed ecological agricultural cycles, products of the chemical industry are not used, which is beneficial for breeding bees.

Consider keeping the most common animals in a closed ecological agricultural cycle.

Rabbits are a very good growing species and one of the few suitable for micro farming. The rabbit is a herbivore, it tolerates any frosts well, does not require water in the cold season, it does well with ice. In winter, cereals are added to the diet. It is very sensitive to relative crossing, therefore, only individuals planned for slaughter can be kept in the enclosures. When kept, it requires daily observation, in case of nasal discharge (runny nose), the formation of "dandruff" or nodules on the ears (and other external signs of any disease), the animal is subject to immediate slaughter. When you follow such a simple rule, you will never use medications that can subsequently enter the body of a person who does not need them.

Sheep cannot be kept completely wild. Breeding sheep also requires breeding work, without which the population is doomed to very rapid extinction. Sheep should not be allowed to come into contact with potentially dangerous places. A place for disinfection of transport, its parking, storage of oils and equipment. The animal does not die from contaminated food, but it becomes unfit for human food from it. Sheep are a very good species for breeding, they require planned slaughter and are very critical to the purity of feed. When sheep are raised in closed ecological agricultural cycles, the meat does not have a pronounced animal odor.

Cows are the most difficult species to grow in a personal subsidiary farm due to the insufficient area allocated for this. One unit of cattle requires at least one hectare of land for grazing and storing feed. Cows are very sensitive to feed variety and quantity. The animal becomes an adult only in the third year of life, and the bull grows into an adult animal only by the age of five. Meat readiness for food, respectively. The quality of the meat does not change when it reaches adulthood. Animals that have not reached adult age do not have a sufficient content of the necessary substances in the meat.

In a closed ecological agricultural cycle, a milk-producing animal is highly desirable. A fermented milk product in combination with milled grain products completely replaces food additives in the diet for raising chickens of various types of poultry. You can of course use worms, but this is costly to provide the required amount of biomass. In nature, this deficiency is compensated by insects. However, air pollution and accumulated toxic substances have reduced the population of insects, which are still very costly to breed in confined areas - as part of the food chain. But this does not mean that it is impossible. This is a separate line of research.

Poultry, one of the essential parts of closed ecological agricultural cycles. The most important birds common for use in closed ecological agricultural cycles are guinea fowl, chicken, turkey, duck, goose.

Purchased chickens and adult poultry of industrial breeds are necessarily vaccinated, the first inoculation is done in the egg before the chick hatches. The vaccinated bird remains the carrier of the diseases from which they were vaccinated. Therefore, any bird must be reared from an egg using an incubator. If you buy a commercial bird and place it with your own, your bird will die because the commercial bird is vaccinated and yours is not.

Purchased chickens and adult poultry of industrial breeds are necessarily vaccinated, the first inoculation is done in the egg before the chick hatches. The vaccinated bird remains the carrier of the diseases from which they were vaccinated. Therefore, any bird must be reared from an egg using an incubator. If you buy a commercial bird and place it with your own, your bird will die because the commercial bird is vaccinated and yours is not.

Poultry droppings have a high content of soil fertilizing substances and in their primary concentration is detrimental even for all weeds. This property of poultry droppings is used to protect deep-rooted plants such as fruit trees during cultivation. Bird droppings are placed at some distance from the trunk on the surface, creating a ring of non-competitive growth, which is subsequently dug up. This makes it possible to fertilize the soil for the fruit tree and remove weeds that interfere with the growth and development of new plantings.

Poultry digestion requires pebbles in the stomach as the bird does not chew food. In addition, the bird lays eggs, for which it needs calcium in almost finished form. Thus, any bird needs fine gravel and limestone all year round, preferably in the form of crumbs or flour.

Guinea fowl is in the first place, since this bird prefers insects in its diet, but they also eat berries with the same pleasure, and if there is a lack of plant food, they will dig out crops and peck at the roots, even if the feeder is full of grain. Guinea fowl, or African chicken, flies and can withstand severe frosts. Like all animals, he does not like humid cold air. Does not die with local frostbite. Does not tolerate related crossbreeding.

Chicken is the most common and unpretentious type of poultry. Chickens used in industrial production are distinguished by high rates in the production of eggs and meat. However, these indicators are achieved with the use of growth stimulants and medicines against the background of special nutrition, which give a quantitative yield of eggs or meat, with a complete loss of their quality. These are not evolutionarily viable hybrids and genetically modified individuals. When breeding, the offspring of industrial poultry loses the quality of an industrially used ancestor, gradually degenerating into viable breeds from which industrial poultry were obtained.

For use in closed ecological agricultural cycles, non-industrial breeds are applicable, which give much less production, but of adequate quality, given that feed is used that ensure a natural existence, which does not provide for an intensification of development, which excludes the ingestion of substances unusual for traditional nutrition into human food.

Chickens will grow for a long time, lay eggs in about a year, but they will not be a synthetic allergen. Poultry meat will have traditional nutritional and health-improving properties, but it will significantly differ in taste from products of intensive poultry farming.