Equipment reliability and integrity management is an important tool for improving business performance. Methods for increasing the reliability and efficiency of technological and power equipment for oil and gas production and transportation Evgeny Anatolyev Smorodov

10.04.2018

Source: Magazine "PROneft"

Management of reliability and integrity of equipment is an important tool for enhancing business efficiency

UDC 338.45: 622.276

V.R. Amirov

PJSC Gazprom Neft

Keywords: reliability, integrity, equipment, risk, costs, efficiency, budget, planning, industrial safety, operational management system (OMS)

V.R. Amirov

Gazprom Neft PJSC, RF, Saint-Petersburg

The article is devoted to improvement of operational efficiency of oil and gas fields and examines one of the key directives of the operational management system (OMS). This direction is the management of reliability and integrity of equipment - implemented by the Deming cycle. A prerequisite of effective management of reliability and integrity is a correct assessment of the current condition of the asset through the risk assessment and registration costs and damages. The risk-based approach allows for comparable levels of direct costs for management of reliability and in- tegrity, to improve the total economic result (direct costs + damage) while reducing the number of failures. In conclu- sion, the assessment of the current state of management of reliability and integrity in Upstream Division of GPN

Keywords: reliability, integrity, equipment, risk, cost, efficiency, budget, planning, production safety, operational management system (OMS)

DOI

: 10.24887/2587-7399-2018-1-10-15

Introduction

The goal of the Etalon program (operational management system (OMS)) of Gazprom Neft is to ensure maximum operational efficiency of the company through the reliability and safety of production activities and the involvement of all employees in the process of continuous improvement. Equipment Reliability and Integrity Management (UNCO) is a set of measures that ensure uninterrupted operation of oilfield equipment throughout the entire period of operation. The importance of this area of production activity is reflected in its separation into a separate element of the OMS.

Direct costs and total economic result

In the context of an objective deterioration of operating conditions in the oil and gas industry (depletion of fields, an increase in the water cut of well production, etc.), it is advisable to assess with a “fresh look” the structure of costs for maintaining the current activities of assets. A significant share (up to 20) is occupied by the costs of the UCO. They are allocated to various items of the asset's budget and can be divided in the following areas (direct costs):

1.1. current repair of equipment;

1.2. overhaul (or replacement) of equipment (partly carried out at the expense of capital investments);

1.3. diagnostics of equipment condition (including examination of industrial safety of equipment with expired service life, measures for corrosion monitoring, etc.);

1.4. equipment protection (including selection of materials, application of protective coatings, corrosion inhibition, etc.).

In addition, in the course of operating activities, additional costs for USCO arise, which also affect the cost of oil production:

2.1. the costs of eliminating equipment failures and eliminating the consequences of these failures;

2.2. fines and payments related to the violation of the integrity and equipment failures.

The third group of costs, or rather, losses that affect the financial result of the asset for the reporting period, includes:

3.1. loss of products associated with violation of the integrity and equipment failures. These three groups of asset costs correlate differently with the risks of compromising equipment integrity. Costs 1.1., 1.2., 1.4. reduce these risks (both probability and consequences), costs 2.1., 2.2., 3.1. arise as a result of realized risks. Costs 1.3. provide an assessment of these risks and do not affect the magnitude of the risk. The efficiency of USCO is assessed by the cumulative economic result, which is the sum of all the above costs. Cumulative Economic Result Management forms the backbone of UCO and includes: planning, implementation, monitoring of implementation and performance evaluation and updating the approach to UCO.

Risk and damage

Valuation of risk and damage - values that characterize the predicted and actual result of activities related to UCO.

Integrity risk is the predicted amount of damage from failures and damage to the integrity of equipment for the planned period. The quality of the assessment of this risk is determined by comparing this assessment with the amount of damage incurred during a given period, taking into account the prevented damage. Since at present the magnitude of damage from failures and violation of the integrity of equipment is not fully taken into account, then the quality of the assessment of the corresponding risk is not easy to determine due to the lack of a comparison base.

Under these conditions, the rationale for the activities associated with USCO can only be confidence that the costs (1.1., 1.2., 1.3., 1.4.) Are significantly less than the damage they should prevent. For new growing assets, this assumption is usually true, but as marginality decreases

business, the question of the validity of these costs is raised.

In general, the activities associated with USCO make economic sense if

where Зi - costs in directions 1.1., 1.2., 1.3., 1.4. during the reporting period; У - damage from failures and violation of the integrity of the equipment during the reporting period (2.1., 2.2., 3.1.); Control - the prevented damage during the reporting period.

In order to economically justify the costs of the USCO, it is necessary to take into account the costs 1.1., 1.2., 1.3., 1.4. for the reporting period, damage from failures and violation of the integrity of equipment (costs 2.1., 2.2., 3.1.), as well as prevented damage during this period.

These tasks are solved within the framework of the organization of appropriate reporting: on the direct costs of the UCO, on the damage from equipment failures and violation of the integrity of the equipment, on the effectiveness of direct costs on the UCO.

Risk-based approach to managing equipment reliability and integrity

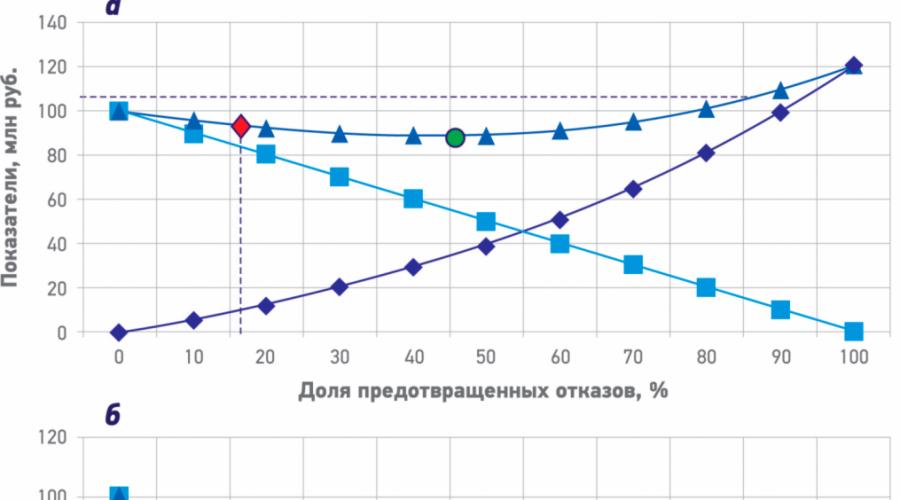

Currently, the oil and gas industry uses mainly two approaches to the UCP. 1. Repair and replacement of equipment is carried out to a minimum upon failure. Equipment diagnostics is carried out in accordance with the requirements of the legislation (technical examination in accordance with safety rules, industrial safety examination for equipment with an expired service life, etc.). The cumulative economic result of this approach is shown in the figure, and in the form of a red diamond and is far from optimal in terms of the number of avoided failures (green circle). This approach is typical for mature assets at a late stage of field development with significant operating costs.

2. Repair and replacement of equipment is carried out in accordance with the standard terms, the manufacturer's recommendations, taking into account the results of the technical examination. Equipment diagnostics is carried out in accordance with the requirements of the legislation (technical examination in accordance with safety rules, industrial safety examination for equipment with an expired service life, etc.).

The cumulative economic result of the implementation of approaches 1 and 2 (a) and the risk-based approach (b)

This approach is typical for developing assets with growing production. The cumulative economic result of this approach is shown in the figure, and a yellow diamond is also not optimal. In addition, the amount of direct costs for the USCO in this case is greater than the damage, and in order to fulfill the above condition, it is necessary to estimate the amount of prevented damage, which, as already noted, is rather difficult.

An alternative is the approach based on assessing the risk of equipment failure and violation of integrity (RBI - Risk Based Inspection, RCM - Reliability Centered Maintenance), which is called risk-oriented. The result of implementing this approach is shown in Figure b. It should be noted that with this approach, the shape of the curve characterizing the damage from failures differs from that shown in the figure, a. This is due to the fact that with a risk-based approach, costs are primarily directed at preventing failures with the most negative consequences (damage to people, the environment, the company's reputation, significant production losses), i.e. unacceptable risks. On the segment of the curve corresponding to 70 - 100 avoided failures, failures with insignificant consequences remain. Comparison of the curves in Figure, a, b shows that the risk-based approach allows, at comparable levels of direct costs for USC, to improve the overall economic result while reducing the number of refusals. The optimal cumulative economic result is shown in figure b with a green circle. This approach is especially effective in companies with different assets (new, developing, mature).

To use a risk-based approach to UCO, two tasks need to be addressed.

1. To carry out a qualitative assessment of the risks of violation of the integrity of various types of equipment for the planned period, including the development and implementation of a calculation model:

- the probability of equipment failure depending on key (internal and external)

factors of influence, which include the service life, the results of technical examination, the state of protection of the equipment, the material of manufacture, the conditions and history of its operation, etc.;

- the consequences of equipment failure, depending on its performance, operating parameters, cost, installation site (in relation to other equipment, personnel locations, settlements, water protection zones, etc.), the time interval for responding to critical deviations of operating parameters, the state of equipment maintainability , the state of external protection and response systems, etc.

2. Generate automated reporting for a certain period

- on the direct costs of the UNCO by type of equipment (1.1, 1.2, 1.3, 1.4);

- about the realized risks of failures and violation of the integrity of equipment (2.1, 2.2, 3.1).

The presented approach is used for short-, medium- and long-term planning of activities related to UCO.

Current state and prospects of the exploration and production unit of the Gazprom Neft PJSC

To solve the first task, the Production Directorate (DP) of the Exploration and Production Unit (MPD) of Gazprom Neft PJSC has developed and is implementing a program for the reliability and integrity of oilfield equipment (NPO), which includes:

- assessment of the risk of violation of the integrity of NGOs through filling out and analyzing scorecards by types of NGOs;

- development, based on this assessment, of a cost planning methodology for the UC NPO;

- formation of subdivisions for USCO in subsidiaries;

- evaluation of the effectiveness of the implementation of the maintenance and repair program for the NPO.

The Directorate for Gas and Energy (DGiE) is currently implementing a pilot project "Creation of a unified system for planning and control of scheduled preventive maintenance of power equipment", the main tasks of which are to reduce the number of repairs and their costs by determining the type and amount of repairs based on an assessment the technical condition of power equipment (RBI) and the balance between the required level of reliability and the cost of maintaining it (RCM). In addition, in the near future DGiE plans to start implementation of the pilot project "Testing of predictive analytics systems on the main equipment of power plants and gas transportation facilities", the task of which is to increase the reliability of operation, reduce the time of unplanned equipment downtime by preventing and eliminating malfunctions at an early stage (RBI) ...

The second task in terms of damage assessment is supposed to be solved by introducing the methodological document MD-16.10-05 “Methodology for the financial assessment of damage from accidents in the field of industrial safety” developed by Gazprom Neft PJSC by separating KT-55 accidents from the existing information systems, which classified as violations of the integrity of equipment (all failures, pipeline bursts, etc.).

Organization of reporting on direct costs for USCO should be carried out on the basis of:

- implementation of the fundamental standard of Gazprom Neft PJSC at the UPCO, the development of which will be completed by the Center for Development of the OMS in 2018;

- analysis of the existing automated management reporting system.

conclusions

1. Aggregate economic result is a key indicator of the effectiveness of activities related to UCO.

2. Implementation and analysis of reporting on costs and damages from failures and violations of the integrity of equipment make it possible to prioritize costs at UCO.

3. The risk-based approach ensures the most efficient allocation of direct costs to UCO.

4. The current state of the USCO in the BRD in terms of both the procedures and the provision of regulatory and methodological documentation allows the implementation of the fundamental standard for the USCO without significant changes to the existing documents.

Improving the reliability and efficiency of the budgeting system in the company LLP "SIKA KAZAKHSTAN"

Enterprises engaged in the production of building mixtures and concrete additives play an important role in the country's economy, since they perform the function of production and provide the state and industrial organizations with resources for all construction necessary for their normal functioning. If in Kazakhstan in the last 5 years there has been a decrease in the construction index by 2-3%, then the Almaty region demonstrates steady growth rates of production of dry and liquid mixtures of concrete additives: the index in 2014 compared to 2013 was 103%. The growth is likely due mainly to an increase in the price of manufactured and imported goods. In fact, the deterioration of fixed assets, insufficient resources and the use of outdated production technologies allow us to speak of the crisis state of the capacities engaged in the production of dry and liquid mixtures in the Almaty region.

Since the end of 2012, namely since the formation of Sika Kazakhstan LLP, the situation began to change for the better, but it is too early to talk about a complete solution of all problems.

There are also specific features in the functioning of these enterprises: the seasonal nature of income from the sale of certain types of products (construction) with a conditionally constant nature of costs; the need to take into account the peak load of the equipment; the presence of certain categories of the company that have benefits for payment for debts, compensation for which occurs with a lag in time.

Naturally, this specificity is also inherent in Sika Kazakhstan LLP.

Currently, it should be recognized that top management recognizes the need to improve the reliability and efficiency of the existing budgeting system in Sika Kazakhstan LLP. Thus, the first step in improving this system has been taken.

The solution to the question of how to reform the system has matured in the course of the activity: it became clear that the further functioning of the budgeting system based on the MS Excel spreadsheet system is unacceptable due to the significant shortcomings of this approach. It was decided to automate this process.

Automation will take a lot of time and resources, but the impact of software implementation is expected to cover all costs.

Automation of the budgeting system will make it possible to clearly and formally determine the main factors characterizing the results of activities, their detailing for each level of management and specific tasks for the heads of structural divisions, ensuring their implementation.

Automation of budgeting will be able to ensure better coordination of economic activities, increase the manageability and adaptability of enterprises engaged in production and resale to changes in the internal and external environment. It is able to reduce the possibility of abuse and errors in the planning system, ensure the interconnection of various aspects of economic activity, form a unified vision of enterprise plans and problems arising in the process of their implementation, provide a more responsible approach of specialists to decision-making and better motivation for their activities.

For setting up a budgeting system, a necessary element is the presence at the enterprise of the main internal regulatory organizational and administrative documents and formalized management processes (rules, description of procedures, etc.). The need for regulation is due to the fact that the formation of information about production, as it were, repeats the course of the production process itself and is predetermined by the movement of material resources through the stages of the technological process and an increase in labor costs as the raw materials are processed. The organizational structure of the enterprise actually ensures the consistency of certain types of economic activities of the enterprise for the implementation of the main tasks and goals. Therefore, the organizational and production structure of an enterprise, its on-farm mechanism are the basis for reforming planning and introducing automated budgeting.

This was taken into account by the management of Sika Kazakhstan LLP, and at present, procedures are already underway to develop and agree on the regulations for the automated budgeting system, which will replace the existing one.

The advantages of automating the budgeting system are as follows:

- 1. The quality of work on the implementation of the strategy is significantly improved, since the strategic goals are formalized and communicated to each department.

- 2. There is an opportunity for a more objective assessment of the contribution of each CFD due to the validity of plans and stimulation of their precise implementation.

- 3. The automated budgeting system provides an assessment of the effectiveness of the developed activities throughout the entire management budgeting cycle.

Thus, the company's management is on the right track, preferring a strategy for responding to the challenges of the time. The measures taken will allow the company to achieve strategic goals and develop its business in the future. But it is very important not to "stray" from the intended path, and this is very likely in the process of solving such a problem as increasing the reliability and efficiency of the company's budgeting system.

To avoid miscalculations, the company's management should expand its cooperation with a wider range of firms offering services for automating budgeting systems in order to be able to choose the most optimal platform option.

In addition, it would be advisable to attract independent specialists as consultants when choosing a system that takes into account the specifics of the activities of Sika Kazakhstan LLP.

In general, the measures taken in the company will allow the implementation of the set goals. But if you ignore the above aspects, the process vector may shift, which still will not allow you to get the full benefit from the implemented system.

1.4.1. Introduction. Self-acting piston compressor valves

Valve- an independent assembly unit as part of a compressor stage. It serves to periodically connect the working chamber to the suction and discharge cavities.

Rice. 5.9. Schematic diagram of the valve.

1 - saddle, 2 - stop, 3 - spring, 4 - shut-off element.

Despite the variety of valve designs, they can be reduced to a single schematic diagram shown in Fig. 5.9. In the general case, the valve consists of a seat 1, a stop 2, a shut-off element 4, and one or more springs 3, and also contains fastening elements for a seat with a stop. In some designs, an elastic element is used as a shut-off element, which simultaneously performs the functions of a spring. When assembled, the valve shut-off element is pressed against the seat and separates cavities with different pressures relative to each other.

In accordance with fig. 5.9 gas flow through the valve is possible only when the shut-off element is moved by a value of 0< h ≤ h кл в случае R 1 > R 2. The condition for the start of movement of the shut-off element is the excess of the gas force acting on the shut-off element over the elastic force of the springs ![]() .

.

The elastic force of the springs at is determined by the ratio

![]()

From this expression it follows that with a known number of springs acting on the valve plate, their stiffness and preload in the assembled valve, the value ![]() .

.

The force is determined by the gas pressures acting on both sides on the frontal surface of the shut-off element, i.e.

where is the coefficient taking into account the shape of the pressure diagram on the surfaces of the shut-off element, determined, as a rule, experimentally. Let's take: ![]() - gas pressure in the cylinder of the compressor stage, variable in the angle of rotation of the shaft at the discharge pressure

- gas pressure in the cylinder of the compressor stage, variable in the angle of rotation of the shaft at the discharge pressure ![]() ... When the condition is met, the valves of the compressor stages are automatically opened. On this basis, they are called self-acting, i.e. automatically opening at a certain pressure difference in the cavities separated by the valve. When the effective differential pressure drops, the valve is automatically closed by the action of the springs.

... When the condition is met, the valves of the compressor stages are automatically opened. On this basis, they are called self-acting, i.e. automatically opening at a certain pressure difference in the cavities separated by the valve. When the effective differential pressure drops, the valve is automatically closed by the action of the springs.

In terms of design, the flow path of the valve is a set of one or more channels of similar changes in cross-sections in the direction of the gas flow to the nozzle. In this case, the cross-sections of the channels at the inlet (from the saddle side) and outlet (from the limiter side) are constant, while the cross-section in the valve slot is minimal, depends on the movement of the shut-off element and changes during operation in the range where is the maximum value of the geometric cross-section of the slot for a fully open valve. The volume of gas contained in the valve channels constitutes the main part of the dead volume of the compressor stage and from this point of view should be minimized.

In essence, the flowing physical processes, the valve can be considered as a local resistance with a geometric section and an equivalent section ![]() , where is the coefficient of gas flow through the valve, which depends on the shape of the valve channels.

, where is the coefficient of gas flow through the valve, which depends on the shape of the valve channels.

A feature of the valves is the occurrence of shock stresses in the valve elements when the shut-off element contacts the seat and stop, the value of which depends primarily on the height of movement of the shut-off element and the compressor shaft rotation speed n.

Pushing the gas through the valve requires an additional expenditure of work proportional to the effective differential pressure

,

,

where is the density of the gas at the entrance to the valve channels;

m is the mass flow rate of the gas through the valve.

From the above expression it follows that in order to reduce the value, the equivalent cross-section of the valve slot should be selected as possible. However, this leads to an increase in the dead space in the valve channels and, as a rule, is accompanied by an increase in the height of movement of the shut-off elements, which deteriorates the efficiency and reliability of the compressor stage.

Considering the above, a number of requirements are imposed on the valve design. Let's highlight the main ones:

1. A high level of valve efficiency, provided by the maximum possible increase in the cross-section of the slot for the given surfaces of the compressor stage, on which the valves are located. At the same time, additional energy consumption in valves is usually limited to the value for stationary compressors and 12 ÷ 15% for mobile and special high-pressure compressors of the indicated capacity.

2. The guaranteed level of reliability, the indicator of which is usually the calculated operating time of the valve to first failure. In modern designs of reciprocating compressors, this value lies in the range from 2 to 10 thousand hours, where the upper limit corresponds to large stationary compressors, and the lower - high-speed low-flow compressors.

These requirements are in conflict with each other. In particular, the desire to improve efficiency tends to reduce the reliability of the valve. Therefore, when designing valves, as a rule, they follow the path of finding a compromise solution.

In addition to the above, a number of additional requirements are imposed on the valves, among which we note the following:

Dynamic tightness, i.e. timeliness of their closure;

Static tightness of valves when closed;

Minimum dead space in valve channels;

Ease of installation, dismantling and maintainability, especially in cases of operation with contaminated gases and in the absence of cylinder lubrication;

Minimum weight and size parameters, cost and delivery time;

Guaranteed service by the manufacturer.

When characterizing the design of valves, 2 main sections of the gas passage channels are usually considered: the section in the seat and in the slot of the fully open valve. In the general case, the quantity is determined by the equation

F u = P ∙ h cl,

where P is the sealed perimeter of the closed valve;

- the maximum amount of movement of the valve plate.

The values of P and for the main types of valves are given in table. 5.3.

Table 5.3

Sectional parameters of the slot of self-acting valves.

Note: L (l), B (b) - dimensions of the shut-off body;

- the average diameter of the annular plate;

- diameter of the opening at the valve inlet;

Z is the number of moving valve elements.

The main task in the preliminary substantiation of the design of the valve of the selected type for the compressor stage under consideration is to determine the required cross-section of the slot, depending on the number of valves Z, the active area of the piston, its average speed with n, and the gas temperature at the valve inlet T, gas constant R and adiabatic exponent k. The relationship of these parameters for a fully open valve is described by the criterion dependence

,

,

where M is the criterion for the gas flow rate in the valve. Its value for modern valve designs lies in the range ![]() ;

;

- valve flow coefficient.

The value for a particular type of valve is usually determined experimentally, considering it depending on the current height of movement of the valve plates. For fully open valves, the values given in table can be recommended. 5.4.

Table 5.4

Flow coefficient of main valve structures

In the reference literature, the valve is characterized by an equivalent cross-section ![]() ... Its value according to the above criterion dependence will be equal to

... Its value according to the above criterion dependence will be equal to

Based on the found value of Ф, a standard valve is selected or a new one with specific geometric parameters is developed.

This method of valve selection does not guarantee the required level of performance and reliability. Therefore, at the final stage, it is advisable to perform a computational analysis of the operation of the selected valves as part of a real compressor stage. For this, proven calculation programs are used that provide for mathematical modeling of a complex of working processes and dynamics of movement of shut-off elements, which allow at the design stage to substantiate the optimal combination of geometric parameters of valve elements in relation to a compressor with a given geometry of stages, known operating parameters and properties of the working substance.

An indicator of the reliability of the developed valves, formed as a result of many years of experience of a number of generations of researchers, manufacturers and consumers of compressor equipment, is the fulfillment of the condition: calculated (at the design stage) or experimentally determined landing speed of valve plates on the seat W s ≤ 1.5 m / s .

The final assessment of the efficiency and reliability of the valves is taken on the basis of extended thermotechnical tests of the compressors, which provide for the determination of the capacity, power consumption, discharge temperatures in stages and the operating time to the 1st failure.

In the materials below, the author sets and solves the problem of development, research and creation of self-acting valves, the efficiency and reliability of which are justified at the design stage when using the modernized KOMDET-M program.

1.4.2. Reciprocating Compressor Valve Optimization Fundamentals

Selection of characteristic parameters of valves according to the value of the equivalent cross-section in the slot fully open valves Ф ш does not guarantee the optimal combination of the design parameters of the valves (thickness δ PL and mass m pl movable valve plates, their maximum movement h cl, hardness WITH pr, numbers Z pr and preload of springs h 0 acting on individual valve plates), and, therefore, does not allow predicting the actual level of static ν pr and dynamic ν per leakage of valves with the overall dimensions or landing diameters selected during the preliminary thermodynamic calculation d 1 . The consequence of this approach is the discrepancy to one degree or another between the calculated and actual productivity, power on the machine shaft and indicators of reliability and efficiency of the stages and the unit as a whole.

Taking into account these factors, it is advisable to perform complex verification calculation as numerical experiment , in the course of which a comparative analysis of the compressor stage options is carried out, equipped with valves of various designs. Based on the results of the numerical experiment, it is recommended that “ optimal variant »Valves, which ensure the required stage performance, the modern level of efficiency and reliability of valves when operating at nominal and other modes.

This aspect of the work is presented in detail in Section 7.

1.4.3. On the advisability of using fungal valves

as part of the stages of opposed compressors

In the literature, “fungal” valves are understood as individual valves with a shut-off element in the form of a round plate, the surface of which from the side of the seat is made along a profile that provides a minimum gas-dynamic resistance during gas flow through the valve channels. The movable body of the valves outwardly resembles a fungus with a spherical "head" facing towards the valve seat. Structurally, fungal valves practically do not differ from valves with spherical plates (see Fig. 5.10-A and 5.10-B). Due to a number of features, valves of this type are used, as a rule, in low-flow positive displacement machines and in high-pressure stages with small cylinder diameters. The existing methods for calculating spherical valves are quite applicable in the analysis of the operation of compressor stages equipped with mushroom valves.

In this section of the work, the author analyzes the feasibility of using fungal valves in the stages of modern high-speed (n ≥ 750 rpm) opposed compressors with double-acting pistons, which predetermines the lateral arrangement of individual valves with a landing diameter d 1 on the side walls of the cylinder.

Since the fungal valves are structurally identical to the spherical ones, their calculated analysis can be performed on the basis of the KOMDET-M application program. The program has proved itself well in the practice of the design and engineering departments of OJSC “KOMPRESSOR”, St. Petersburg at the stage of development and substantiation of optimal options for low-flow compressors of low, medium and high pressure on Y-shaped bases.

Rice. 5.11. Stackable fungal valve

with non-metallic shut-off bodies

with a landing diameter of 125 mm (Z cl = 20)

The main advantage of poppet valves (fungal and spherical) with non-metallic shut-off bodies their increased tightness is considered when closed.

The main disadvantage- low utilization factor of the frontal surface of the valve plate with a landing diameter d 1, within which the n-th number of spherical or fungal valves is installed (see Fig. 5.11).

The object of the study was the 1st stage of the 4GM2.5-6.67 / 4-50S gas compressor with double-acting pistons. The working cavities of the stage (A and B) can be completed with various types of individual valves with a landing diameter of ø125 mm and placed on the lateral surface of the cylinder. In the course of a numerical experiment, the efficiency of the stage was evaluated when it was equipped with direct-flow (PIK), tape (LU), strip (PC) and fungal valves while maintaining the operating parameters.

At the preliminary stage of the study, the optimal amount of lift of the locking organ of the fungal valve was determined. The results of the study are shown in table. 5.6. Their analysis made it possible to substantiate the optimal variant of the GrK125-20 valve -14 -2.0 with a hole diameter in the saddle d c = 14 mm and a rise height of the shut-off body h cl.opt = 2 mm.

The results of the 2nd stage of the study are given in table. 5.7 and fig. 5.12 in the form of current and integral parameters of a compressor stage equipped with valves of various types, allow us to draw the following conclusions:

1. Composite mushroom valves mounted in a plate with a bore diameter of ø125, when located on the side surface of the cylinder lose valves of other types according to the main indicators, including:

Decrease in productivity - by 4.3%;

Increase in the total relative losses in the valves χ VS + ng by a factor of 2;

Decrease in isothermal indicator efficiency η iz.ind - by 8.0%;

Increase in discharge gas temperature - by 14 K.

Table 5.6

Integral parameters I stage compressor 4GM2.5-6.67 / 4-50S when equipped with mushroom-type valves with variable lifting height h cl

| Options | Dimension | Number and type of valves installed: | ||||

| Z cl = 1 sun + 1 ng, type - Fungal | ||||||

| Valve designation I st. | - | GrK125- 20-14-1.5 | GrK125- 20-14-1.8 | GrK125- 20-14-2.0 | GrK125- 20-14-2.2 | GrK125- 20-14-2.5 |

| h cl | mm | 1.5 | 1.8 | 2.0 | 2.2 | 2.5 |

| R ng / R sun | MPa | 1.2 / 0.4 | ||||

| P = R ng / R sun | - | 3.0 | ||||

| a | 0.34 | |||||

| T sun | TO | |||||

| T st | 345.2 | 334.9 | 343.1 | 342.9 | 342.7 | |

| T ng.ts | 433.5 | 430.3 | 428.3 | 427.8 | 427.4 | |

| m 1.A | kg / h | 513.44 | 517.26 | 519.94 | 518.58 | 523.88 |

| V n.o. 1A | nm 3 / min | 7.1011 | 7.154 | 7.1911 | 7.1723 | 7.2455 |

| N ind. 1A | kw | 20.470 | 20.150 | 19.961 | 19.826 | 19.974 |

| N number 1A | 16.736 | 16.781 | 16.841 | 16.796 | 16.938 | |

| ∆N ∑ | 3.634 | 3.369 | 3.120 | 3.030 | 3.036 | |

| χ sun | - | 0.118 | 0.108 | 0.103 | 0.103 | 0.100 |

| χ ng | 0.105 | 0.093 | 0.082 | 0.077 | 0.079 | |

| L beats | kJ / kg | 143.5 | 140.2 | 138.2 | 137.6 | 137.3 |

| h sun | 528.87 | |||||

| h ng. S | 637.43 | |||||

| h ng | 670.56 | 667.33 | 665.24 | 664.66 | 664.33 | |

| η from.ind | - | 0.643 | 0.658 | 0.667 | 0.670 | 0.672 |

| λ | 0.5304 | 0.5344 | 0.5372 | 0.5358 | 0.5412 | |

| λ d | 0.9521 | 0.9632 | 0.9664 | 0.9609 | 0.9709 | |

| λ t | 0.9619 | 0.9631 | 0.9642 | 0.9658 | 0.9639 | |

| λ about | 0.5669 | 0.5733 | 0.5746 | 0.5719 | 0.5769 | |

| ∆λ sun | - 0.0225 | - 0.0123 | - 0.0104 | - 0.0139 | - 0.0131 | |

| ∆λ ng | 0.0026 | 0.0021 | 0.0007 | 0.0005 | 0.0041 | |

| ρ 3 | kg / m 3 | 9.919 | 9.962 | 9.988 | 9.984 | 10.005 |

| ρ 1 | 4.362 | 4.418 | 4.437 | 4.419 | 4.458 | |

| ρ 3 / ρ 1 | - | 2.274 | 2.255 | 2.251 | 2.259 | 2.244 |

| W s.ws | m / s | 1.14 | 0.91 | 0.96 | 1.21 | 2.26 |

| W s.ng | 1.94 | 1.93 | 1.39 | 1.42 | 2.42 |

Option code - GM25-6.7-4-12-G. Working cavity - A.

AIR, D c. I = 200 mm, S p = 110 mm, L w = 220 mm, n = 980 rpm, s p = 3.593 m / s

Table 5.7

Options I stage booster compressor 4GM2.5-6.67 / 4-50S

when equipped with valves of various types

Z cl = 1 + 1, δ conventional cl = 1 μm, real ρ = 4.7635 kg / m 3

| Options | Dimension | Execution option I stage | |||

| A | B | V | G | ||

| Valve type | - | PIK125- 1.0BM-1.5 | LU125-9- 96-8-0.6-1.8 | PK125-9- 96-8-0.6-1.8 | GrK125- 20-14-2 |

| T ng | TO | 412.9 | 414.6 | 413.7 | 428.3 + 14K |

| m 1.A | kg / h | 532.3 | 545.4 | 542.2 | 519.9 |

| V n.o. 1A | nm 3 / min | 7.362 | 7.544 | 7.499 | 7.191 - 4.3% |

| V sun 1A | m 3 / min | 1.862 | 1.908 | 1.897 | 1.819 |

| N ind. 1A | kw | 18.221 | 18.809 | 18.568 | 19.961 |

| ∑∆N cl | 1.036 | 1.502 | 1.392 | 2.957 2 times | |

| χ sun | - | 0.034 | 0.048 | 0.044 | 0.103 |

| χ ng | 0.026 | 0.039 | 0.037 | 0.082 | |

| η from.ind | 0.749 | 0.743 | 0.748 | 0.667 -8% |

Rice. 5.12. Current parameters of the 1st stage of the compressor

4GM2.5-6.67 / 4-50С at n = 980 rpm

GrK125-20-12-2 ------ PK125-9-96-8-0.6-1.8

2. High frequency and amplitude of oscillation of valve springs during the periods of suction and discharge (see Fig. 5.12) contribute to their premature failure.

Summarizing the data obtained, it should be noted that the use of a set of mushroom valves in a round valve plate as part of the stages of large opposed compressors with double-acting pistons at high shaft speeds is not advisable. An exception may be individual cases of using mushroom valves when completing steps low-speed compressors compressing "heavy" - "light" gases (for example, AIR - Hydrogen and Hydrogen-containing mixtures) during the period of commissioning tests.

Bibliography

1. Prilutsky I. K., Prilutsky A. I. Calculation and design

reciprocating compressors and expanders on normalized bases:

Textbook for university students. - SPbGAHPT, 1995. - 194 p.

2. Reciprocating compressors: a textbook for university students.

B.S. Fotin, I.B. Pirumov, I.K. Prilutsky, P.I. Plastinin.

- L .: Mashinostroenie, 1987 .-- 372 p.

3. Frenkel M. I. Piston compressors.

- L .: Mashinostroenie, 1969 .-- 744 p.

- M .: Mashinostroenie, 1979 .-- 616 p.

4. Catalog of electric motors. Branch of Elkom LLC. - Moscow, Russia

Voroshilov - Ryzhkov:

1. Booster compressors without cylinder cooling -

heat problem(experiment and Kolesnev) +

lid ribbing(experiment with the participation of a representative of the KKZ and Galyaev ??)

2. Unification of valves of I and II stages of compressor 4GM2.5-6.67 / 11-64

3. Rational technical solutions Masha, Damping, Unification - Z cl 3: 1 (PAI)

4. Rectangular valves of transport compressors - an alternative to individual round valves, forced by the average piston speed and shaft rotation frequency (UKZ-Demakov and KKZ)

5. Development of the base 4U4, forced by average speed ………….

6. The achieved technical level of the compressors.

Prospects for its further increase

7. Comprehensive computational and theoretical analysis (2ВМ2.5-14 / 9) ……… ..

"METHODS OF INCREASING THE RELIABILITY AND EFFICIENCY OF PROCESS AND POWER EQUIPMENT IN THE PROCESSES OF PRODUCTION AND TRANSPORTATION OF OIL AND GAS ..."

As a manuscript

SMORODOV EVGENY ANATOLIEVICH

METHODS TO INCREASE RELIABILITY

AND EFFICIENCY OF TECHNOLOGICAL

AND POWER EQUIPMENT IN PROCESS

PRODUCTION AND TRANSPORTATION OF OIL AND GAS

Specialties: 05.02.13 - "Machines, Units and Processes"

(oil and gas industry)

05.26.03 - "Fire and Industrial Safety" (oil and gas industry)

Dissertation for the degree of Doctor of Technical Sciences

The work was carried out at the Ufa State Oil Technical University.

Scientific consultant Doctor of Technical Sciences, Professor Baikov Igor Ravilievich.

Official opponents: Doctor of Technical Sciences, Associate Professor Novoselov Vladimir Viktorovich;

Doctor of Technical Sciences, Associate Professor Yamaliev Vil Uzbekovich;

Doctor of Technical Sciences, Professor Gumerov Rif Sayfullovich.

Leading organization"Center for Energy Saving Technologies of the Republic of Tatarstan" under the Cabinet of Ministers of the Republic of Tatarstan.

The defense will take place on February 20, 2004 at 14-00 at a meeting of the Dissertation Council D 212.289.05 at the Ufa State Oil Technical University at the address: 450062, Republic of Bashkortostan, Ufa, st. Cosmonauts, 1.

The dissertation can be found in the library of the Ufa State Petroleum Technical University.

Scientific Secretary of the Dissertation Council Ibragimov I.G.

GENERAL DESCRIPTION OF WORK

Relevance Problems. Ensuring the reliability of operation and industrial safety of oil and gas facilities in modern society is the most important task. Technological processes for the extraction and transport of hydrocarbon raw materials are potentially hazardous in nature, which is associated with large volumes of combustible organic raw materials extracted in the fields and transported over long distances.Major accidents at the enterprises of the industry lead to environmental disasters, the elimination of the consequences of which requires significant financial costs, and it takes many years to restore the natural environment.

The level of reliability of technical systems in the oil and gas industry has a direct impact on production efficiency. The problems of increasing the efficiency of the oil and gas industry are closely related to the task of reducing production costs, in particular, for energy resources and carrying out repair and restoration measures. In turn, these tasks are determined by the technical condition of the equipment in the industry, and, therefore, their solution is possible by developing measures to improve the reliability of equipment and improve methods of technical diagnostics.

At present, objective conditions have appeared to solve the listed problems. First of all, they are due to the widespread introduction of microprocessor technology into oil and gas technologies, which allows obtaining production information in qualitative and quantitative terms, which is not comparable with that available 5-10 years ago. Information measuring systems (IMS) allow you to receive, accumulate and save for an almost unlimited time arrays of production data, which include not only the current operating parameters of the equipment, but also the electronic databases of dispatch services.

Particular attention should be paid to the development of new mathematical methods for data processing and building on their basis models of technical systems, the use of which has become possible at the present time. These include methods of synergetics and dynamic chaos, fuzzy logic, game-theoretic methods, neural networks and cellular automata, and many others, developed and successfully applied in areas such as economics and finance, meteorology, geophysics, emergency forecasting, but not found wide application in industrial sectors.

The general structure of the task of increasing the reliability and efficiency of oil and gas enterprises can be represented in the form of a simplified diagram (Fig. 1). The basis for the formulation and solution of the problem is the initial data of the IMS, on the basis of which mathematical models are built that describe the characteristics of objects and the process of their development in time. These can be indicators of equipment reliability, parameters characterizing the current technical condition of an object, or a separate parameter that determines the efficiency of a particular technological process.

The construction of an adequate model of a technical system, a separate object, a piece of equipment or its unit is aimed at obtaining a forecast of changes in technical parameters or reliability parameters over time. The forecast, in turn, allows you to make informed decisions on carrying out maintenance activities, planning repair activities, equipping repair and technical services with the necessary equipment and completing a reserve fund of equipment.

An integral part of the problem of increasing the reliability of operation and energy efficiency of enterprises is the development of methods for rational energy supply. The energy component in the cost of hydrocarbons reaches 15%, and the continuity of technological processes in the oil and gas industry is directly related to the uninterrupted supply of energy.

Increasing the efficiency of enterprises is achieved by solving the entire complex of the listed tasks.

- & nbsp– & nbsp–

Production efficiency is an important aspect of the problems of the oil and gas complex. Efficiency is understood, first of all, the level of costs of all possible resources, including energy, to maintain the functioning of the enterprise. Production costs, as one of the main components of production costs, are currently a serious obstacle to the competitiveness of Russian hydrocarbons in the international market. Therefore, in recent years, the development and implementation of energy and resource saving technologies is urgently required.

The development of methods for solving the listed problems should be based on the increased level of quality and volume of initial information provided by automated control and diagnostic systems widely used in industry enterprises.

The purpose dissertation work is to increase the efficiency and industrial safety of oil and gas enterprises by developing methods for managing the parameters of the reliability of equipment operation and reducing production costs for maintenance and energy resources.

Main goals

research:

1. Development of methods for diagnosing and predicting the parameters of the reliability of equipment operation based on the construction of models of technological systems for the production and transport of hydrocarbon raw materials.

2. Creation of systems of diagnostic parameters for assessing the current technical condition and residual life of equipment based on the integrated use of information from automated data collection devices.

3. Development of theoretical foundations and practical methods of operational control of the technical state of oil and gas transport systems using statistical, phenomenological and dynamic models.

4. Increasing the efficiency of oil and gas equipment operation based on optimal planning of repair and restoration measures.

5. Development of a methodology for calculating the cost of maintaining repair and recovery services, allowing to minimize damage from accidents of technological equipment.

6. Development of methods to improve the reliability and efficiency of power equipment operation, taking into account variable loads resulting from changes in operating conditions and the technical condition of power consumers.

7. Development of theoretical foundations for planning the territorial distribution of facilities and communications of oil and gas enterprises in order to improve the reliability of power supply and reduce energy losses, equipment recovery time and capital costs during the construction of communications facilities.

8. Improving the reliability of power supply systems for fields based on the creation of principles for the placement of autonomous energy sources.

Methods for solving problems. When solving the problems posed, we used probabilistic and statistical methods, elements of the theory of deterministic chaos, methods of game theory, queuing theory, methods for solving transport optimization problems. To confirm the conclusions and implement the methods and algorithms proposed in the dissertation work, industrial information was used, obtained by the information-measuring system "Skat-95" at a number of oil fields in Western Siberia, a database of computer measuring and control systems of compressor stations of LLC "Bashtransgaz", data from vibro- and gas-dynamic diagnostics of TsPTL LLC "Bashtransgaz", data from dispatch logs of OJSC "Uraltransnefteprodukt" and other production information.

Scientific novelty is as follows:

1. The necessity of collecting and permanent storage of the entire volume of production and diagnostic information is substantiated, and it is shown that such information is of great value in terms of developing advanced diagnostic methods based on mathematical processing of large volumes of initial data, such as methods of mathematical statistics, dynamic chaos, development of simulation models, etc.

2. It is shown that it is necessary to take into account the time dependence of the flow of equipment failures caused by changes in the characteristics of the field during its development. The proposed three-parameter model for predicting the uptime of oil and gas production equipment makes it possible to more than double the reliability of forecasts.

3. It is shown that various types of equipment failures are deterministic at the location of accidents, and statistically significant relationships have been established between the types of failures and technological parameters of well operation.

4. A technique for analyzing vibration diagnostics data has been proposed, which makes it possible to take into account the destructive effect of stochastic processes in complex technical systems and provides recognition of developing defects in oil and gas transportation equipment, which is not available to traditional methods.

5. A set of methods for optimal planning of the timing of repairs of oil production and gas transmission equipment has been developed, allowing to minimize losses of the enterprise and based on a retrospective analysis of databases of automated measuring systems on the dynamics of the decline in well rates and numerical solutions obtained on the basis of a simulation model. The proposed methods make it possible to take into account not only the characteristics of equipment reliability, but also the influence of factors such as current prices for raw materials and the negative impact of the maintenance activities themselves.

6. The article presents theoretical provisions for determining the strategy for choosing the types and locations of autonomous energy sources on the territory of the fields, which make it possible to increase the reliability of power supply to oil and gas fields and reduce the cost of consumed heat and electricity.

Are brought to the defense the results of scientific developments in the field of modeling technological processes and improving diagnostic methods in order to increase the reliability of the operation of technological equipment and ensure energy efficiency and industrial safety of oil and gas facilities.

Practical value and the implementation of the work. Methods and algorithms for predicting the timing of failures of underground oil production equipment, developed in the dissertation work, are included in the automated system for monitoring oil production parameters "Skat-95". This system is operated at a number of oil producing enterprises in Western Siberia.

The use of the proposed methods allowed increasing the reliability of forecasts of failure of ESP pumps by 2-5 times.

Methods for calculating the frequency of cleaning activities proposed in the dissertation were tested at OJSC "Uraltransnefteprodukt". The studies carried out have shown the high efficiency of the method and the accuracy of the estimates sufficient for practical use.

The calculation results were used in planning the treatment of oil product pipelines "Salavat-Ufa", "Ufa-Kambarka", "Sineglazovo-Sverdlovsk".

The methods for determining the technical condition and energy efficiency of gas turbine units developed in the dissertation work have been tested by the Bashtransgaz DPTL service and are used to monitor the technical condition of the gas turbine unit.

Proposals and recommendations on the principles of selection and territorial placement of autonomous power plants are considered by OOO Urengoygazprom, OAO Gazprom, TPP Kogalymneftegaz, TPP Uraineftegaz, TPP Langepasneftegaz, TPP Pokachineftegaz.

Approbation of work.

Basic Provisions works were reported at the following seminars, scientific and technical councils and conferences:

1. All-Russian scientific and technical conference "Novoselovskie readings" (Ufa, 1998).

2. 5th International Scientific Conference "Methods of Cybernetics of Chemical Technological Processes" (Ufa, 1999).

3. III All-Russian conference "Regional problems of energy conservation and ways to solve them" (N.-Novgorod, 1999).

4. Interregional scientific and methodological conference "Problems of the oil and gas industry" (Ufa, 2000).

5. Scientific-practical conference "Energy saving in chemical technology - 2000" (Kazan, 2000).

6. All-Russian scientific conference "Energy saving in RB", (Ufa, 2001).

7. International conference dedicated to the 50th anniversary of FTT USPTU (Ufa, 2002).

- & nbsp– & nbsp–

The dissertation work consists of an introduction, five chapters, main conclusions; contains 315 typewritten pages, 32 tables, 84 figures, a bibliographic list of 240 titles.

In the introduction substantiated the relevance of the topic of dissertation work.First chapter is devoted to the analysis of modern methods of modeling technical systems of the oil and gas industry, the analysis of methods of control and regulation of the parameters of reliability of equipment for the production and transport of oil and gas is carried out, and ways to reduce the cost of consumed energy resources are considered.

The analysis showed that the existing models for predicting the reliability of oil and gas equipment are static and do not take into account the dynamics of changes in the characteristics of the object over time. At the same time, there are a large number of well-developed mathematical methods that make it possible to simulate real physical processes in complex technological systems. Until recently, the implementation of these methods was restrained by the lack of a sufficient amount of initial information, which, as a rule, was used as data from dispatch logs. Thanks to the introduction of automation and computer technologies in the oil and gas industry and the accumulated large volumes of operational data, it became possible to create and use algorithms and computer programs that implement modern modeling methods that can significantly increase the level of operational reliability of oil and gas facilities.

The main methods of diagnostics of the technical condition of oil and gas transmission power equipment are considered and it is shown that they do not have the required reliability. Thus, the analysis of the results of vibration diagnostics of gas-pumping units showed that in many cases the development of defects is not recognized using the existing methods of processing vibration signals. It is concluded that it is necessary to expand the set of diagnostic features and improve the methods of processing diagnostic data, which allow to adequately assess the current technical condition of power machines.

- & nbsp– & nbsp–

Fig. 4. Comparison of predictive capabilities of models of varying complexity.

The cause of the accident is the clogging of the working parts of the pump with sand. Interval "a" is the basis for the forecast, interval "b" is the forecast. 1 - polynomial of the 1st degree; 2 - polynomial of the 2nd degree; 3 - polynomial of the 3rd degree; Triangle markers - actual data just before total failure Field equipment failures are relatively rare events, and therefore sample sizes for emergency repairs and / or equipment replacements over a period of time when operating conditions can be considered unchanged. In addition, reliable information about technological equipment failures stored in the databases of modern automated systems covers a time interval of 5 years. Taking into account the mean time between failures and the total number of units of the same type of equipment, such a volume of information does not exceed 10-20 life cycles of the technological equipment of oil fields. Therefore, the problem arises of modeling the reliability parameters taking into account the small volume 0.9 0.85

- & nbsp– & nbsp–

0,75 0,7 0,65 0,6 0,55

- & nbsp– & nbsp–

Fig. 5. The average value of the Hurst exponent for various types of sampling failures for emergency events and the requirement for the highest forecast accuracy.

To solve this problem, a comparison of the forecast accuracy (based on retrospective data) for three methods of constructing an optimal model is carried out - the least squares method, methods for minimizing the average risk and methods of the theory of fuzzy sets. At the same time, it was found that in conditions of small sample sizes, the most reliable forecasts are provided by the model recommended by the methods of the theory of fuzzy sets.

It is impossible to predict an accident in case of instantaneous failures by such methods. In this case, it is necessary to find some "precursors" of an accident that would react to the approach of failure with practically constant operating parameters of the well.

Fractal characteristics of the flow rate time series can be such a precursor. Studies have shown that chaotic changes in the flow rates of oil producing wells are of a deterministic nature, and the fractal characteristics of the time series of flow rate measurements make it possible to detect developing defects that are not available to traditional methods (Fig. 5).

In custody of the second chapter, the influence of the high-frequency component of the load in the rod string caused by resonance phenomena on the reliability of operation of sucker rod pumping units is considered. To assess the degree of danger of this type of variable loads, a mathematical model of a sucker rod pumping unit (SRPU) has been developed, which describes the dynamic loads in a rod string, and the main dependences of their destructive effect on the technical characteristics of the equipment and the physical properties of the produced fluid have been determined. The relationship between the probability of bar breakage and the amplitude of dynamic loads was revealed, recommendations for their reduction were given.

- & nbsp– & nbsp–

Fig. 10. Spectrograms of the acoustic signal, the notion of turbulent flows excited by the ball valve a) - hermetically sealed valve; b) - a leaky tap;

gas. A turbulent gas jet, when outflowing from a hole or when flowing around a body placed in the flow, generates acoustic vibrations, the frequency of which depends on the characteristic dimensions of the damage and the parameters of the moving medium (Fig. 10).

The generated oscillations have a wide spectrum, which is associated with physical processes leading to the generation of acoustic waves, namely, the formation and disruption of gas vortices. Each elementary vortex has certain physical and energy characteristics, but since the parameters of elementary vortices are largely random, the spectrum of acoustic vibrations in different time intervals is different.

If we introduce the concept of an "instantaneous" spectrum, meaning by this the spectrum of oscillations for a sufficiently short time interval t = 1 / f0, (4) where f0 is the lowest frequency spectrum component of interest to us, then we can say that the narrow-band "instantaneous" spectrum performs stochastic displacement in a certain frequency range, the average frequency fav of which is related to the Strouhal number

- & nbsp– & nbsp–

Consequently, the study of the spectral and statistical laws of acoustic characteristics makes it possible to obtain information on the geometric dimensions of the emitting object and the velocity (flow rate) of the gaseous medium. Knowing the average frequency of the noise band in the acoustic spectrum, from relation (5) it is possible to obtain estimates of the characteristic size of damage D at the valve seal and the amount of gas leakage Q. For the spectrum shown in Fig. 10 (fav = 1750 Hz), we have

- & nbsp– & nbsp–

which is about one percent of the gas pumped by the GTK-10 unit and is commensurate with the flow meter error. The advantage of the proposed diagnostic method is the ability to carry out measurements without stopping the crane.

In the third section of the chapter, the possibility of constructing a diagnostic phenomenological model is considered, which makes it possible to calculate the efficiency of a gas turbine without using additional measurements.

The actual task of monitoring the technical condition of equipment is research aimed at developing methods for calculating the parameters of equipment operation, which require additional measurements that are not provided by standard instruments. These include, in particular, methods for calculating the efficiency of pumping and compressor units. Each of the nodes of the mechanical system can be characterized by some resulting parameter, which is a criterion for the technical condition of this node. For example, for the GPU as a whole, the value of the overall efficiency of the unit or the residual service life can be taken as an assessment of the technical condition.

Let us denote the i-th unit operation parameter recorded by the standard devices by xi, then the technical condition Yj of the j-th unit can be determined as a function of the parameters, i.e. Yj = fj (X), where X = (xi).

Each of the registered parameters xi changes over time, and the recording is made at regular intervals with an interval t, i.e. tk = nt, where n is the number of the measurement in the series. Therefore, the recorded time series of parameter values can be represented as xi = xi (tk). The calculated indicator of the technical condition Yj will also be a time series Yj (tk), which makes it possible to study the trend of the technical condition and predict the defects of oil and gas equipment.

The effective efficiency of a gas turbine unit depends on the operating mode of the GPU and is a known function of many operating parameters: = F (X), where X = (xi) is a set of parameters measured (including by non-standard means) for calculations. With the passage of time, with changes in the operating mode of the GPU, the parameters also change, i.e. xi = xi (tj), and efficiency j = F (tj).

On the other hand, it is possible to represent a complex function F with a simpler (for example, linear) function of the parameters xk (measured by standard instruments) with unknown constant coefficients:

N * j = F * (t j) = A0 + Ak xk (t j), (6) k = 1

- & nbsp– & nbsp–

time series of parameters xk (tj) and efficiency (tj) and setting the level of reliability of the correlation.

The coefficients Аk are calculated from the condition of minimization of the functional F (X) -F * (X) min. (7) In a similar way, the task is to determine other diagnostic indicators - the coefficients of technical condition for power, efficiency or fuel gas.

Figure 11 shows a comparison of the efficiency calculated according to the standard method (requiring additional measurements) with the calculations according to the proposed model. The error of the calculated K values is 2% and is systematic, while the curves are equidistant. Therefore, we can assume that the regression equations obtained using the proposed procedures are sufficiently accurate, and with their help it is possible to assess the coefficients of the technical state of the GPU.

The advantages of the proposed method are the use of only standard measurements, the efficiency of the calculation and the possibility of including the developed algorithm in the IMS functions of the compressor station to display the current technical state of each of the units.

The fourth chapter is devoted to the issues of rational maintenance of hydrocarbon production and transportation facilities.

In the first section of the chapter, possible schemes for organizing maintenance of oil and gas production and transportation facilities are considered, which make it possible to minimize production costs and reduce damage from equipment downtime.

Analysis shows that more than half of equipment defects are evolving over time. Typical times for the full development of a defect, for example, in oil production, is a time interval of up to 90 days.

Carrying out repair work immediately after the detection of a developing defect is impractical, since the equipment has not yet fully exhausted its resource, and replacing it with a new one requires significant costs. On the other hand, the operation of equipment with a developing defect leads to a decrease in profit due to a decrease in oil production. In addition, the downtime of the well was also unprofitable during the restoration work. Thus, it is necessary to solve a multi-criteria optimization problem - to determine the moment of the start of repair work, at which the damage to the enterprise from a decrease in oil production will be minimal. Let us consider the solution to the posed problem of optimizing the timing of repair work under the assumption that the function describing the decrease in the flow rate Q (t) of the well has already been defined and parameterized.

Let us take as the beginning of the time t = 0 the moment of the beginning of the flow rate decrease.

The profit of the enterprise obtained from the operation of the well during this period is determined by the income from the sale of the product slave

- & nbsp– & nbsp–

B C. (11) slave + slave + slave + C rem + c el P slave = 0 cQ0 Equation (11) represents an algebraic equation of the third degree for the desired solution slave, which can be calculated using Cardano's formulas.

Calculations given taking into account the operating time of pumping equipment between failures have shown that, subject to the implementation of these recommendations, the specific profit of an oil producing enterprise increases by 5-7%.

A similar problem arises when planning repair work on gas transmission equipment. The paper proposes a simulation model that allows, on the basis of statistical data on failures of gas transmission equipment elements, to calculate the optimal overhaul period for the operation of gas pumping units. The developed model can be used for planning the calendar dates of scheduled preventive and overhaul repairs of gas compressor units of any type.

The model adopted for calculations has the following structure.

Suppose that the GPU consists of N elements, for each of which it is possible to determine the integral function of the MTBF distribution Fi (t), 1iN. The emergency failure of the unit is considered to have occurred when at least one element fails. After an emergency failure, repairs are carried out, which fully or partially restore the resource of the failed GPU element. There is also the possibility of carrying out scheduled preventive repairs of one or several elements, as well as those of major repairs in which the GPU resource is fully restored.

To carry out calculations, it is necessary to know the form and parameters of the distribution laws Fi (t), which can be obtained from the analysis of statistical data on emergency failures of the GPU. It is known that the initial section of operation, counted from the moment of starting up the GPU after overhaul, is the most dangerous in the sense of unexpected failures, which is typical for most technical devices. Failures at the initial stage of operation are associated with the development of hidden defects after poor-quality repairs, their intensity decreases rather quickly over time (running-in period). After the end of the running-in period, failures mainly occur as a result of physical wear of the GPU elements, and the failure distribution function in this case corresponds to the normal law.

To determine 0.08

- & nbsp– & nbsp–

where N is the drive power, kW;

Q - nominal capacity, m3 / day.

The graph of the dependence Z = Z (Q), calculated according to the given formula based on the characteristics of the pumps and built for the height of the liquid rise in the range of 600-1000 m, is shown in Fig. 16. It follows from the graph that the efficiency of a pumping and power unit depends on its performance and varies from ~ 0.35 at Q = 30-50 m3 / day to ~ 0.70 at Q 100 m3 / day.

Based on the data on the structure of the pumping fleet and well flow rates, we will calculate the unit costs for the field as a whole (for the actual structure of the park

ESP):

- & nbsp– & nbsp–

the operating ESP park.

Estimated real costs Fig. 16. The calculation of unit costs according to the passport data was carried out according to the data of the modified ESP.

rhenium of the total flow rate of wells equipped with ESP, and the total power consumed by pumping equipment. The IIS “Skat-95”, which was put into operation at the studied field, makes it possible to carry out such assessments. So, at the time of measurements, the total daily flow rate of oil wells in terms of liquid was 35031 m3 / day, while the actual total power of the drive motors was 9622 kW. Calculation by relation (26) in this case gives Z = 6.6 kWh / m3. Thus, the actual specific energy consumption is almost twice the lower limit for this field.

The analysis carried out in order to clarify the reasons for the discrepancy between the actual and theoretically possible for the conditions of the given field of specific energy consumption, revealed the following main reasons:

Significant heat losses in the power cable due to the small cross-section of conductive conductors;

Inconsistency of the supply voltage at the transformer substation with the nominal or phase imbalance;

Losses in transformers;

Poor technical condition of the pump, engine or tubing.

One of the methods to reduce irrational losses of electrical energy is to ensure a rational load of transformer substations. This problem is solved in the dissertation work by developing an algorithm for calculating the loads, which allows to optimize the distribution of the load of transformer substations of oil and gas fields, taking into account possible changes in the actual power of energy consumers.

Irrational loading of technological equipment leads to a reduction in the resource of its operation and at the same time increases the specific energy consumption for the extraction of hydrocarbon raw materials. This fully applies to cluster transformer substations (KTP), the installation of which was carried out in most cases at the initial stages of development of oil and gas fields.

As a result of the drop in oil production, the previously operated KTPs in the nominal mode turned out to be either underloaded or overloaded in most cases. Statistical analysis of the IMS "Skat-95" databases showed that the general rule at present is the underloading of the transformer substation by 40-60%. Moreover, the distribution of the load between the KTP (if there is more than one KTP on the well cluster) in the real case can be completely random.

It should also be noted that the load of the transformer substation does not remain constant over time. For example, the failure of one of the pumps leads to a decrease in the load. Taking into account the waiting time for repair (10-30 days) and the repair itself (3-5 days), the resulting irrational distribution of loads leads to a significant overspending of electricity.

To increase the reliability of operation of cluster transformer substations and reduce irrational losses of electricity, it is necessary to solve the problem of distribution of loads between the KTP taking into account the actual performance of the pumping equipment and the temporary nature of the change in connected loads caused by emergency shutdown of pumps.

Let us formalize the problem statement as follows. There are n KTP serving m wells. All KTPs operate with underload (on the left branch of the efficiency curve). It is necessary to redistribute the load of consumers between the KTP so that the total losses of electricity are the least.

The comparative analysis of the characteristics of the efficiency of transformers showed that the most reliable in the class of elementary functions the left branch of the efficiency curve is described by a function of the form = a (1 exp (N)), (28) where is the efficiency of the transformer;

a, - empirical coefficients;

N - power consumption.

Consider the function Y characterizing the work of the KTP group:

n n = i = ai (1 exp (i N i)). (29) i = 1 i = 1 In the physical sense, maximization of the functional corresponds to the minimum heat losses in the magnetic circuit and the windings of the transformer group.

Obviously, the left-hand side of equation (29) will reach its maximum value when the quantity n

- & nbsp– & nbsp–

Dependence (31) allows you to calculate the optimal load of each transformer in the group, if the total power consumption of the cluster equipment is known.

Comparison of the numerical value of the total efficiency of a group of transformers, obtained as a result of optimization of the distribution of loads, with the case of the existing distribution of loads, showed that the power losses at the KTP serving the well cluster are reduced by at least 2%. Taking into account the fact that the number of transformers in NGDU can reach several thousand, the energy savings will be very significant. The proposed algorithm makes it possible to increase the durability of the transformer substation and power equipment by bringing the degree of their load closer to the nominal.

In the conclusion of the chapter, the issues of rational energy supply of oil and gas enterprises are considered.

To improve the energy security of the operation of oil and gas producing enterprises, increase the reliability of power supply and reduce losses during transmission and transformation, as well as to reduce the cost of electric and thermal energy, at present, the oil and gas industry is increasingly using autonomous energy sources. In this case, the problem arises of choosing the type, capacity and location of autonomous power units, taking into account their reliability, working life, cost and minimum energy losses during its transmission to consumers.

The paper analyzes the operational characteristics of industrial mini-power plants of domestic and foreign production. It is shown that according to the criteria "durability - cost of electricity - reliability", the priority for oil and gas production enterprises are sectioned gas piston mini-power plants with a capacity of 1 ... 5 MW, operating on associated gas.

At present, a fairly extensive market of autonomous energy sources has developed, and the task of reconstruction is reduced to the choice of the optimal type and capacity of power plants and their territorial location, both from the point of view of reliable power supply to the fields, and from the point of view of reducing the specific energy consumption for oil and gas production.

The task of choosing the optimal power supply system for oil and gas fields should be solved taking into account the territorial location and capacity of both consumers and sources of electrical energy. Therefore, the formulation of the optimization problem should be carried out individually for each field.

The initial information for the calculations is a large-scale map of the field, on which all energy-consuming objects (well clusters, water injection pumps, etc.) are plotted with an indication of their installed capacity.

The analysis shows that the consumption of electricity within the field has a pronounced uneven character. The energy consumption surface has a number of local extrema, the location of which corresponds to the areas of maximum and minimum energy consumption.

The object placement problem for this case is formalized as follows.

On the territory of the field, it is necessary to place n autonomous power sources with a known total power N0 kW so that the load of the power consumers corresponds to their nominal indicators, and the total heat losses in the power lines are minimal.

Let m existing objects (well clusters, pumping stations and other consumers) be located at different points P1,…, Pm of the plane, and new objects (autonomous power sources) - at points X1… Xn. The distance between the points of location of the j-th new and i-th existing objects will be denoted as d (Xj, Pi). Let's designate the annual specific energy losses in the cable between the j-th new and i-th existing object through wij = F1 (Ni). Then the total annual energy losses are defined as m f (X) = wij d (X j, Pi), (32) i = 1

- & nbsp– & nbsp–

where E i = (x a i) + (y b i) +.

(h) (h) 2 (h) 2 The calculation of the optimal location of autonomous power units, carried out according to these iterative formulas, allows you to determine the location of an arbitrary number of sources (Fig. 17).

The proposed algorithm allows not only to increase the reliability of power supply to oil and gas field facilities, but also to reduce by 2 ... 5 times the loss of electricity in power lines.

GENERAL CONCLUSIONS