Overview: the global coal generation market. Types and types of modern thermal power plants (TPP)

Read also

Since 2000, the world's coal-fired generating capacity has doubled to 2,000 GW as a result of the explosive growth of investment projects in China and India. Another 200 GW is under construction and 450 GW is planned worldwide. In recent decades, coal-fired power plants have produced 40-41% of the world's electricity - the largest share in comparison with other types of generation. At the same time, the peak in electricity generation from coal was reached in 2014, and now the ninth wave of decreasing the load of operating TPPs and their closure has begun. More about this in our Carbon Brief review.

Since 2000, the world's coal-fired generating capacity has doubled to 2,000 GW as a result of the explosive growth of investment projects in China and India. Another 200 GW is under construction and 450 GW is planned worldwide. There are 77 countries in the coal generators club, 13 more plan to join it by 2030.

In recent decades, coal-fired power plants have produced 40-41% of the world's electricity - the largest share in comparison with other types of generation.

At the same time, the peak in electricity generation from coal was reached in 2014, and now the ninth wave of decreasing the load of operating TPPs and their closure has begun. Over the years, the EU and the US have closed 200 GW, another 170 GW must be shut down by 2030. As of April 9, 2018, 27 countries have joined the Coal Phase-Out Alliance, of which 13 have operating power plants.

Note that from 2010 to 2017, only 34% of the planned coal capacity was built or put into construction (873 GW), while 1,700 GW was canceled or postponed, reports CoalSwarm. For example, a tender for the construction of one new station may attract several bids, each of which will be counted towards the “planned capacity”.

According to the International Energy Agency (IEA), all untreated coal plants should shut down within a few decades if warming is to be limited to less than 2C above pre-industrial temperatures. To shed light on this story, Carbon Brief has mapped the past, present and future of all coal-fired power plants in the world as of February 2018. (https://www.carbonbrief.org/mapped-worlds-coal-power-plants), which shows all coal-fired TPPs over 30 MW each, operating in the period 2000-2017, as well as the location of the planned. The map includes about 10,000 closed, operating and planned coal plants with a total capacity of 4,567 GW, of which 1,996 GW is in operation today, 210 GW is under construction, 443 GW is planned, 2,387 GW are being discontinued and 1,681 GW were proposed to be built, but then canceled since 2010 in 95 countries of the world. There are also about 27 GW of small coal-fired thermal power plants in the world - up to 30 MW each.

Increase in coal capacity

Coal generation is primarily about the promise of cheap electricity to spur economic growth. Global coal-fired generation capacity grew annually between 2000 and 2017, almost doubling from 1.063 GW to 1.995 GW. Coal produces 40-41% of the world's electricity, the largest share in recent decades. Today coal energy is used by 77 countries of the world compared to 65 in 2000. Another 13 plan to join the coal energy club.

CO2 emissions from existing plants are enough to break the carbon budget by 1.5 or 2 degrees Celsius. According to the study, these restrictions would mean no new coal-fired power plants and the early closure of 20% of the coal-fired fleet. All raw coal power plants will have to close by 2040 to keep the world “well below” 2 degrees Celsius growth, according to the IEA. This would mean shutting down 100 GW of coal capacity every year for 20 years, or roughly one coal block every day until 2040.

However, newspaper headlines and energy forecasts suggest coal growth will not stop. These grim prospects for a worsening climate are tempered by signs of rapid changes in the energy sector. The conveyor belt for coal blocks under construction or planned has been halved since 2015. The pace of TPP closings is accelerating, reaching a cumulative level of 197 GW between 2010 and 2017.

Slowdown in coal growth

IEA believes that investment peak to the world coal energy has already passed and the industry has entered a phase of "dramatic slowdown". The IEA report says that China, which provides most of the current growth, no longer needs new thermal power plants.

A failure in investment means that growth in coal capacity is slowing. And if in 2011 82 GW was commissioned in the world, then in 2017 - only 34 GW.

The number of new stations under construction is declining faster every year, down 73% since 2015, according to the latest annual report from CoalSwarm, Greenpeace and Sierra Club. China is shutting down many hundreds of smaller, older and less efficient facilities, replacing them with larger and more efficient ones. All this means that global power coal generation may peak as early as 2022, said in a report on the state of the IEA industry.

Peak CO2 emissions

IEA data show that CO2 emissions from coal energy, perhaps already peaked in 2014 ., despite the fact that the coal capacity continues to grow. Coal CO2 emissions fell 3.9% between 2014-2016, coal production fell 4.3%.

As the capacity of coal continues to increase, existing coal-fired power plants run for fewer hours. On average, global coal-fired power plants were in operation for about half the time in 2016, with a utilization rate of 52.5%. A similar trend is observed in the US (52%), the EU (46%), China (49%) and India (60%).

A number of other factors also influence the relationship between coal-fired power plants and CO2 emissions. These include the type of coal and combustion technologies used by each plant. Thermal power plants burning low-quality lignite can emit up to 1200 tons of CO2 per GWh of electricity generated. High quality coal emits fewer emissions.

Combustion technology is also important, from less efficient "subcritical" installations to ultra-supercritical systems that increase the efficiency of the boiler at higher pressures. The oldest and least efficient subcritical units operate at 35% efficiency. New technologies raise this indicator up to 40%, and ultra-supercritical up to 45% (HELE).

However, according to the World Coal Association, even HELE coal blocks emit around 800tCO2 / GWh. This is about twice the emissions of a gas power plant and about 50-100 times higher than nuclear, wind and solar. The IEA sees no further prospect for coal-fired power in pre-2C scenarios as residual emissions are too high, even with carbon capture and storage.

There was a small spike in coal production and CO2 emissions in 2017, driven by increased production in China, although these remain below the 2014 peak.

Erosion of the coal economy

The low level of utilization of power plants (CCI) is "corrosive" for the economy of coal-fired TPPs. In general, they are designed to operate at least 80% of the time, as they have relatively high fixed costs. This is also the basis for the cost estimate for the construction of the new coal block, while lower utilization increases the cost per unit of electricity. The downward trend in CCI is particularly toxic for coal-fired power plant operators, competing with rapidly falling renewable energy prices, cheap gas in the US and soaring coal prices in the EU. Coal supply restrictions are driving up coal prices, further undermining any remaining benefits over alternatives.

New environmental regulations are driving up the cost of coal-fired power plants in many jurisdictions from the EU to India and Indonesia. Coal plant owners must invest in wastewater treatment plants to meet higher environmental standards, or close their dirty power plants altogether. This combination of factors means that most stations in the existing coal fleet in the EU and even India are facing serious economic problems, according to the Financial thinktank Carbon Tracker. It was found that by 2030, for example, almost all coal-fired power plants in the EU will be unprofitable. Bloomberg New Energy Finance founder Michael Libreich says coal is facing two "tipping points." The first is when new renewable energy becomes cheaper than new coal-fired power plants, which has already happened in several regions. Second, when new renewable energy sources are cheaper than existing coal-fired power plants.

note that coal-fired power plants can continue to operate in unfavorable economic conditions, for example, with a surcharge for power. This practice was introduced by a number of EU countries in 2018.

In 2018, China, Vietnam and Thailand completely canceled the solar surcharge. The Philippines and Indonesia have significantly reduced it. And in India, solar generation is already cheaper than coal. That is, in conditions of real competition, coal generation in countries Southeast Asia is already losing out to RES and will develop more slowly than planned.

Key countries and regions

77 countries use coal to generate electricity, up from 65 in 2000. Since then, 13 countries have built coal facilities and just one country - Belgium - has closed them. Another 13 countries, which account for 3% of current capacity, have pledged to phase out coal by 2030 under the Coal Left of the Past Alliance, led by the UK and Canada. Meanwhile, 13 countries still hope to join the coal energy club.

Top 10 the countries of the world shown on the left side of the table below account for 86% of the total number of coal-fired power plants in operation. On the right in the Table - Top 10 countries planning to build 64% of the world's coal-fired capacity.

Country / operating MW / share in the world Country / MW under construction / share

China 935.472 47% China 210.903 32%

USA 278.823 14% India 131.359 20%

India 214.910 11% Vietnam 46.425 7%

Germany 50,400 3% Turkey 42,890 7%

Russia 48.690 2% Indonesia 34.405 5%

Japan 44.578 2% Bangladesh 21.998 3%

South Africa 41.307 2% Japan 18.575 3%

South Korea 37,973 2% Egypt 14,640 2%

Poland 29.401 1% Pakistan 12.385 2%

Indonesia 28,584 1% Philippines 12,141 2%

China has the largest operating coal-fired fleet and is home to the largest pipeline of 97 GW under construction in a 250 km radius along the Yangtze River Delta around Shanghai. This is more than already exists in any country with the exception of India and the United States. Russia has the fifth largest coal-fired fleet in the world, accounting for only 2% of the world's generating capacity.

China

Over the past 20 years, the most significant changes have taken place in China. Its coal-fired fleet grew fivefold between 2000 and 2017. and reached 935 GW, or almost half of the world's capacity.

China is also the world's largest emitter of CO2 and uses half of the world's coal, so its future path is disproportionately important to the global effort to combat climate change.

Industrial activity and the use of coal were stimulated prior to the appointment of Chairman Xi as a "leader for life." This energy policy could push CO2 emissions to the fastest pace in years.

However, some analysts say China's coal use could be cut in half by 2030. The government is introducing a national emissions trading scheme, and is closing and restricting new coal-fired power in response to air pollution and climate concerns. This means that the conveyor belt of coal-fired thermal power plants under construction or planned in 2017 decreased by 70% by 2016, CoalSwarm reports.

It also means the planned projects are unlikely to get the permits they need to build them, says Lauri Millivirta, an energy analyst at Greenpeace in East Asia. “Many of the planned projects in China and India are virtually dead. In India they are commercially illiquid, no one in their right mind is going to build them ... in China it makes no sense, because there is already too much capacity, a surplus. " According to the United States Energy Information Administration (EIA), power and coal production in China are more or less at their peak.

India

The second largest increase in capacity since 2000 occurred in India, where the coal-fired power fleet more than tripled to 215 GW. Recently, the state of the Indian coal generation has deteriorated sharply. IEA cut its forecast for demand for Indian coal due to a slowdown in the growth of demand for electricity and a reduction in the cost of renewable energy sources. Some 10 GW plants are deemed "unsustainable," others 30 GW are under "stress," according to the Indian Energy Minister in an interview with Bloomberg in May 2018. This is because "India's renewable energy revolution is pushing coal off the debt cliff." Matthew Gray, Analyst at Carbon Tracker.

India's latest national electricity plan targets the disposal of 48 GW of coal-fired power plants, in part due to new environmental standards. It also provides for the commissioning of 94 GW of new capacities, but this figure is considered unrealistic by key analysts of the world. The country has planned the commissioning of 44 GW projects, of which 17 GW have been suspended for many years. " In India, renewables can already supply energy at a lower cost than new and even most existing coal-fired power plants. "Says Lauri Millivirta, energy analyst at Greenpeace East Asia.

USA

The wave of disposal of old capacity has cut US coal generation by 61 GW in six years, and another 58 GW is planned to be closed, Coal Swarm notes. This will reduce the US coal fleet by two-fifths, from 327 GW in 2000 to 220 GW in the future or below.

One way to save the industry is through the Trump administration's announced plans to rescue unprofitable coal-fired power plants for national security reasons in order to maintain system reliability with power surcharges Bloomberg describes them as "unprecedented intervention in the US energy markets."

On the other hand, market conditions currently favor gas-fired power plants and renewable energy sources. There are no new coal facilities in the United States. It is expected that the decommissioning of coal capacities in 2018 will amount to 18 GW. Last year, coal consumption in the U.S. power sector was the lowest since 1982.

European Union

Given the EU's plans to phase out coal, the union's coal-fired fleet should be reduced to 100 GW by 2030, or half of its total capacity in 2000. Along with Canada, EU countries lead the Alliance to phase out coal. Great Britain, France, Italy, the Netherlands, Portugal, Austria, Ireland, Denmark, Sweden and Finland have announced the phase-out of coal-fired power plants by 2030. Their capacity is 42 GW, including recently built power plants.

At the same time, the fourth and ninth largest national coal generating fleet in the world is located in member states EU, namely 50 GW in Germany and 29 GW in Poland. An EU commission to set a cut-off date for coal-based electricity supplies for Germany has begun to work, although the country's grid operator says only half of its coal fleet could be closed by 2030 without compromising energy security. Poland simply promised that it would not build new coal-fired thermal power plants beyond what is already being built.

IEA studies have shown that all EU coal-fired power plants must close by 2030 in order to meet the goals of the Paris Agreement. Rising CO2 prices are expected to lead to a shift from coal to gas this year, subject to suitable prices and gas availability.

Other key countries

Other Asian countries, including South Korea, Japan, Vietnam, Indonesia, Bangladesh, Pakistan and the Philippines, have collectively doubled their coal-generating fleet since 2000, reaching 185 GW in 2017. In total, these countries will build 50 GW of new thermal power plants on their own and 128 more. GW is planned through financing and participation in the construction of China, Japan and South Korea.

In many of these countries, there are mixed signs of coal use. For example, the latest draft of Japan's National Energy Plan takes into account the significant role of coal in 2030, while the Paris Agreement means that Tokyo should phase out coal by then, Climate Analytics notes.

Vietnam is the third country in terms of the planned volume of coal generation - 46 GW, of which 11 GW is already under construction. “Nonetheless, the government is increasingly investing in changing this trajectory,” writes Alex Perera, deputy director of energy at The World Resources Institute. “Vietnam provides an interesting and important combination of conditions that will enable the transition to clean energy: renewable energy and the private sector striving to meet increasingly stringent clean energy targets. "

The Indonesian government has banned the construction of new coal plants on the most populous island of Java. The state utility company has been criticized for “massively overestimating the growth in electricity demand” in order to justify plans to commission new coal-fired power plants.

Turkey has significant plans to expand its coal fleet. However, currently only 1 GW is being built from the planned 43 GW pipeline.

Another country with big plans is Egypt, which has neither coal stations nor coal deposits of its own. Please note that none of the 15 GW planned new capacity has gone beyond the earliest stage of approvals, received any permits and is not under construction.

South Africa has large coal deposits and the seventh largest coal power fleet in the world. South Africa is building 6 GW of new thermal power plants and plans to introduce another 6 GW. However, after the election of Kirill Ramaphosa earlier this year, political sentiment in the country is changing, and long-term deals for the construction of renewable energy sources worth $ 4.7 billion were signed in April. ... The reason is that new coal stations will be more expensive than RES, experts say. Legislative discussions over the role of coal in South Africa's new energy investment plan will take place later this summer.

In 1879, when Thomas Alva Edisoninvented the incandescent lamp, the era of electrification began. The production of large quantities of electricity required cheap and readily available fuel. Coal met these requirements, and the first power plants (built at the end of the 19th century by Edison himself) operated on coal.

As more and more stations were built in the country, the dependence on coal increased. Since World War I, roughly half of the US's annual electricity production has come from coal-fired power plants. In 1986, the total installed capacity of such power plants was 289,000 MW, and they consumed 75% of the total amount (900 million tons) of coal mined in the country. Given the existing uncertainties regarding the prospects for the development of nuclear energy and the growth of oil and natural gas production, it can be assumed that by the end of the century, coal-fired thermal power plants will produce up to 70% of all electricity generated in the country.

However, despite the fact that coal has long been and will be the main source of electricity for many years (in the United States, it accounts for about 80% of the reserves of all types of natural fuels), it has never been the optimal fuel for power plants. The specific energy content per unit weight (i.e., the calorific value) of coal is lower than that of oil or natural gas. It is more difficult to transport and, in addition, burning coal causes a number of undesirable environmental consequences, in particular, acid rain. Since the end of the 60s, the attractiveness of coal-fired power plants has sharply declined due to the tightening of requirements for environmental pollution with gaseous and solid emissions in the form of ash and slag. The costs of solving these environmental problems, along with the increasing cost of building complex facilities such as thermal power plants, have made their development prospects less favorable from a purely economic point of view.

However, if the technological base of coal-fired thermal power plants is changed, their former attractiveness may be revived. Some of these changes are evolutionary in nature and are aimed primarily at increasing the capacity of existing installations. At the same time, completely new processes of waste-free combustion of coal are being developed, i.e. with minimal damage to the environment. The introduction of new technological processes is aimed at ensuring that future coal-fired thermal power plants can be effectively controlled for the degree of environmental pollution, have flexibility in terms of the possibility of using various types of coal and do not require long construction times.

In order to appreciate the significance of advances in coal combustion technology, consider briefly the operation of a conventional coal-fired thermal power plant. Coal is burned in the furnace of a steam boiler, which is a huge chamber with pipes inside, in which water turns into steam. Before being fed into the furnace, the coal is crushed into dust, due to which almost the same completeness of combustion is achieved as when burning flammable gases. A large steam boiler consumes an average of 500 tons of pulverized coal per hour and generates 2.9 million kg of steam, which is enough to generate 1 million kWh of electricity. During the same time, the boiler emits about 100,000 m3 of gases into the atmosphere.

The generated steam passes through a superheater, where its temperature and pressure are increased, and then enters a high-pressure turbine. The mechanical energy of the turbine rotation is converted by an electric generator into electrical energy. In order to obtain a higher energy conversion efficiency, steam from the turbine is usually returned to the boiler for reheating and then drives one or two low pressure turbines before being condensed by cooling; condensate is returned to the boiler cycle.

Thermal power plant equipment includes fuel feeding mechanisms, boilers, turbines, generators, as well as complex cooling systems, flue gas cleaning and ash removal. All of these primary and secondary systems are designed to operate reliably for 40 years or more at loads that can range from 20% of the plant's installed capacity to maximum capacity. The capital cost of equipment for a typical 1,000 MW thermal power plant is typically in excess of $ 1 billion.

The efficiency with which the heat released by burning coal can be converted into electricity was only 5% before 1900, but by 1967 it had reached 40%. In other words, over a period of about 70 years, the specific consumption of coal per unit of generated electricity has decreased eightfold. Accordingly, the cost of 1 kW of installed capacity of thermal power plants also decreased: if in 1920 it was $ 350 (in 1967 prices), then in 1967 it dropped to $ 130. The price of electricity supplied also fell over the same period from 25 cents to 2 cents per kWh.

However, starting in the 1960s, the pace of progress began to decline. This trend, apparently, is explained by the fact that traditional thermal power plants have reached the limit of their perfection, determined by the laws of thermodynamics and the properties of materials from which boilers and turbines are made. Since the early 1970s, these technical factors have been exacerbated by new economic and organizational reasons. In particular, capital expenditures have sharply increased, the rate of growth in demand for electricity has slowed down, requirements for environmental protection from harmful emissions have become more stringent, and the timeframes for the implementation of power plant construction projects have been lengthened. As a result, the cost of generating electricity from coal, which had a long-term downward trend, has risen sharply. Indeed, 1 kW of electricity generated by new thermal power plants now costs more than in 1920 (in comparable prices).

Over the past 20 years, the cost of coal-fired power plants has been most influenced by stricter requirements for the removal of gaseous,

liquid and solid waste. Gas cleaning and ash handling systems in modern thermal power plants now account for 40% of capital costs and 35% of operating costs. From a technical and economic point of view, the most significant element of an emission control system is a flue gas de-sulphurization plant, often referred to as a wet (scrubber) dust collection system. A wet dust collector (scrubber) traps sulfur oxides, which are the main pollutants formed during coal combustion.

The idea of wet dust collection is simple, but in practice it turns out to be difficult and expensive. An alkaline substance, usually lime or limestone, is mixed with water and the solution is sprayed into the flue gas stream. Sulfur oxides contained in flue gases are absorbed by alkali particles and precipitate out of solution in the form of inert sulphite or calcium sulphate (gypsum). Gypsum can be easily removed or, if clean enough, marketed as a building material. In more complex and expensive scrubber systems, gypsum sludge can be converted to sulfuric acid or elemental sulfur, which are more valuable chemical products. Since 1978, the installation of scrubbers has been mandatory at all pulverized coal-fired thermal power plants under construction. As a result, the US energy industry now has more scrubber units than the rest of the world.

The cost of a scrubber system at new plants is usually $ 150-200 per 1 kW of installed capacity. The installation of scrubbers at existing plants, originally designed without wet gas cleaning, is 10-40% more expensive than at new plants. The running costs of scrubbers are quite high whether they are installed in old or new plants. Scrubbers generate a huge amount of gypsum sludge, which must be kept in sedimentation ponds or dumped, which creates a new environmental problem. For example, a 1000 MW thermal power plant operating on coal containing 3% sulfur produces so much sludge per year that they can cover an area of 1 km2 with a layer about 1 m thick.

In addition, wet gas cleaning systems consume a lot of water (at a 1000 MW plant, water consumption is about 3800 l / min), and their equipment and pipelines are often prone to clogging and corrosion. These factors increase operating costs and reduce overall system reliability. Finally, in scrubber systems, from 3 to 8% of the energy generated by the station is consumed for driving pumps and smoke exhausters and for heating flue gases after gas cleaning, which is necessary to prevent condensation and corrosion in chimneys.

The widespread adoption of scrubbers in the American power industry has not been simple or cheap. The first scrubber installations were significantly less reliable than the rest of the station equipment, therefore the components of the scrubber systems were designed with a large margin of safety and reliability. Some of the difficulties associated with the installation and operation of scrubbers can be attributed to the fact that industrial application of scrubber technology was prematurely started. Only now, after 25 years of experience, has the reliability of scrubber systems reached an acceptable level.

The cost of coal-fired power plants has risen, not only because of the mandatory presence of emission control systems, but also because the cost of construction itself has skyrocketed. Even taking inflation into account, the unit cost of the installed capacity of coal-fired thermal power plants is now three times higher than in 1970. Over the past 15 years, the "economies of scale", that is, the benefits from the construction of large power plants, have been offset by a significant increase in the cost of construction ... This rise in price partly reflects the high cost of financing long-term capital construction projects.

The impact of the delay in project implementation can be seen in the example of Japanese energy companies. Japanese firms are usually more agile than their American counterparts in dealing with the organizational, technical and financial problems that often delay the commissioning of large construction projects. In Japan, a power plant can be built and commissioned in 30-40 months, while in the United States, a plant of the same capacity usually takes 50-60 months. With such long project implementation times, the cost of a new plant under construction (and, therefore, the cost of frozen capital) is comparable to the fixed capital of many US energy companies.

Therefore, energy companies are looking for ways to reduce the cost of building new power generation plants, in particular by using modular units of lower capacity, which can be quickly transported and installed in an existing plant to meet growing demand. These plants can be brought online in a shorter time frame and therefore pay for themselves faster, even if the ROI remains constant. Installing new modules only when an increase in system capacity is required can result in net savings of up to $ 200 per kW, although economies of scale are lost with smaller units.

As an alternative to building new power generating facilities, utilities have also practiced retrofitting existing old power plants to improve their performance and extend their service life. This strategy naturally requires less capital expenditures than building new stations. This trend is justified also because the power plants built about 30 years ago are not yet morally obsolete. In some cases, they work even with higher efficiency, since they are not equipped with scrubbers. Old power plants are gaining an increasing share in the country's energy sector. In 1970, only 20 electricity generating facilities in the United States were over 30 years old. By the end of the century, 30 years will be the average age of coal-fired thermal power plants.

Utilities are also looking for ways to reduce plant operating costs. To prevent energy losses, it is necessary to provide timely warning of the deterioration in the performance of the most important areas of the facility. Therefore, continuous monitoring of the state of components and systems is becoming an important part of the operational service. Such continuous monitoring of natural processes of wear, corrosion and erosion allows plant operators to take timely measures and prevent emergency failure of power plants. The significance of such measures can be correctly assessed if we consider, for example, that the forced downtime of a 1000 MW coal-fired plant could bring the energy company losses of $ 1 million per day, mainly because the unreported energy must be compensated for by supplying electricity from more expensive sources.

The rise in the unit costs of transporting and processing coal and of ash removal has made the quality of coal (determined by moisture, sulfur and other minerals) an important factor in determining the performance and economics of thermal power plants. Although low-grade coal can cost less than high-grade coal, its consumption for the production of the same amount of electricity is much higher. The cost of transporting more low-grade coal may offset the benefit of its lower price. In addition, low-grade coal usually generates more waste than high-grade coal, and therefore requires high ash removal costs. Finally, the composition of low-grade coals is subject to large fluctuations, which makes it difficult to "tune" the station's fuel system to work with the maximum possible efficiency; in this case, the system must be adjusted so that it can operate at the worst grade expected.

In existing power plants, the quality of the coal can be improved or at least stabilized by removing some impurities, such as sulfur-containing minerals, before combustion. In treatment plants, crushed "dirty" coal is separated from impurities in many ways, taking advantage of differences in specific gravity or other physical characteristics of the coal and impurities.

Despite these efforts to improve the performance of existing coal-fired power plants, an additional 150,000 MW of power capacity will need to be operational in the United States by the end of the century if electricity demand grows at the expected rate of 2.3% per year. To keep coal competitive in the ever-expanding energy market, utilities will have to adopt innovative new methods of burning coal that are more efficient than traditional ones in three key respects: less pollution, less time to build power plants, and better performance and performance. ...

|

|

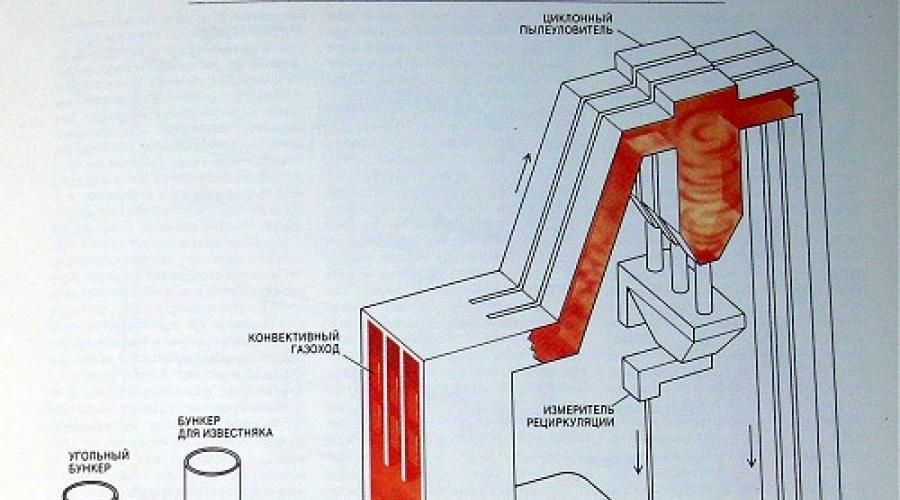

| BURNING COAL IN A LIQUID LAYER reduces the need for ancillary emission treatment plants from the power plant. A fluidized bed of a mixture of coal and limestone is created in the boiler furnace by an air flow, in which solid particles are mixed and are in suspension, that is, they behave in the same way as in a boiling liquid. Turbulent mixing ensures complete combustion of coal; in this case, limestone particles react with sulfur oxides and trap about 90% of these oxides. Since the heating coarse of the boiler is directly in contact with the fluidized bed of fuel, steam generation is more efficient than in conventional coal-fired steam boilers. In addition, the temperature of the burning coal in the fluidized bed is lower, which prevents melting boiler slag and reducing the formation of nitrogen oxides. |

COAL GASIFICATION can be carried out by heating a mixture of coal and water in an oxygen atmosphere. The product of the process is a gas consisting mainly of carbon monoxide and hydrogen. Once the gas has been cooled, de-soldered and freed from sulfur, it can be used as fuel for gas turbines and then to produce steam for a steam turbine (combined cycle). The combined cycle plant emits less pollutants into the atmosphere than a conventional coal-fired thermal plant. |

Currently, more than a dozen methods of coal combustion with increased efficiency and less damage to the environment are being developed. The most promising among them are fluidized bed combustion and coal gasification. Combustion according to the first method is carried out in the furnace of a steam boiler, which is arranged in such a way that crushed coal mixed with limestone particles is maintained above the grate of the furnace in a suspended ("pseudo-liquefied") state by a powerful ascending air flow. Suspended particles behave essentially the same way as in a boiling liquid, that is, they are in turbulent motion, which ensures a high efficiency of the combustion process. The water pipes of such a boiler are in direct contact with the "fluidized bed" of burning fuel, as a result of which a large proportion of heat is transferred by thermal conductivity, which is much more efficient than radiative and convective heat transfer in a conventional steam boiler.

A boiler with a firebox, where coal is fired in a fluidized bed, has a larger heat transfer pipe surface area than a conventional boiler that runs on pulverized coal, which allows to reduce the temperature in the furnace and thereby reduce the formation of nitrogen oxides. (If the temperature in an ordinary boiler can be higher than 1650 ° C, then in a boiler with combustion in a fluidized bed it is in the range of 780-870 ° C.) Moreover, limestone mixed with coal binds 90 or more percent of the sulfur released from coal during combustion, since the lower operating temperature promotes the reaction between sulfur and limestone to form sulfite or calcium sulfate. Thus, substances harmful to the environment, formed during the combustion of coal, are neutralized at the place of formation, i.e. in the furnace.

In addition, a fluidized bed boiler is less sensitive to fluctuations in coal quality in terms of its design and operating principle. In the furnace of a conventional pulverized coal boiler, a huge amount of molten slag is formed, which often clogs the heat transfer surfaces and thereby reduces the efficiency and reliability of the boiler. In a fluidized bed boiler, coal is burned at a temperature below the melting point of the slag, and therefore the problem of clogging the heating surfaces with slag does not even arise. Such boilers can operate on lower quality coal, which in some cases can significantly reduce operating costs.

The fluidized bed combustion method is easily implemented in modular boilers with low steam output. According to some estimates, the investment in a thermal power plant with compact boilers operating on the principle of a fluidized bed may be 10-20% lower than the investment in a traditional thermal power plant of the same capacity. Savings are achieved by reducing construction time. In addition, the capacity of such a station can be easily increased with an increase in the electrical load, which is important for those cases when its growth in the future is not known in advance. The planning problem is also simplified, since such compact units can be quickly assembled as soon as the need arises to increase power generation.

Fluidized bed boilers can also be incorporated into existing power plants when generating capacity needs to be rapidly increased. For example, the energy company Northern States Power converted one of the pulverized coal boilers at the station in pcs. Minnesota in a fluidized bed boiler. The alteration was carried out in order to increase the power of the power plant by 40%, reduce the requirements for the quality of fuel (the boiler can even operate on local waste), more thorough cleaning of emissions and lengthen the service life of the station up to 40 years.

Over the past 15 years, the technology used in thermal power plants equipped exclusively with fluidized bed boilers has expanded from small pilot and pilot plants to large "demonstration" plants. Such a plant with a total capacity of 160 MW is being built jointly by Tennessee Valley Authority, Duke Power and Commonwealth of Kentucky; Colorado-Ute Electric Association, Inc. commissioned a 110 MW power generating unit with fluidized bed boilers. If these two projects are successful, and that of Northern States Power, a private sector joint venture with a combined capital of about $ 400 million, the economic risk associated with the use of fluidized bed boilers in the power industry will be significantly reduced.

Another method, which, however, already existed in a simpler form back in the middle of the 19th century, is the gasification of coal to produce "purely burning" gas. Such gas is suitable for lighting and heating and was widely used in the United States until World War II, when it was replaced by natural gas.

Initially, coal gasification attracted the attention of energy companies, who hoped to use this method to obtain fuel that burns without waste and thereby eliminate scrubbing. It has now become apparent that coal gasification has an even more important advantage: the hot combustion products of the generator gas can be directly used to drive gas turbines. In turn, the waste heat of the combustion products after the gas turbine can be utilized in order to obtain steam for driving a steam turbine. This combined use of gas and steam turbines, called a combined cycle, is now one of the most efficient ways to generate electrical energy.

The gas obtained by gasification of coal and freed from sulfur and particulate matter is an excellent fuel for gas turbines and, like natural gas, burns with almost no waste. The high efficiency of the combined cycle compensates for the inevitable losses associated with the conversion of coal to gas. Moreover, the combined cycle plant consumes significantly less water, since two-thirds of the capacity is developed by a gas turbine, which does not need water, unlike a steam turbine.

The viability of coal gasification combined cycle power plants has been proven by the Southern California Edison Cool Water plant. This station with a capacity of about 100 MW was put into operation in May 1984. It can operate on different types of coal. The emissions from the station are no different from those of the neighboring natural gas station in terms of purity. The sulfur oxides in the flue gas are kept well below the target by an auxiliary sulfur recovery system that removes almost all the sulfur in the feed fuel and produces pure sulfur for industrial purposes. The formation of nitrogen oxides is prevented by the addition of water to the gas before combustion, which lowers the combustion temperature of the gas. Moreover, the remaining unburned coal in the gasifier is remelted and converted into an inert vitreous material that, after cooling, meets the California solid waste requirements.

In addition to the higher efficiency and lower environmental pollution, combined cycle plants have another advantage: they can be built in several stages, so that the installed capacity is increased in blocks. This flexibility in construction reduces the risk of over- or under-investment associated with the uncertainty of growth in electricity demand. For example, the first stage of the installed capacity can operate on gas turbines, and use oil or natural gas instead of coal as fuel, if the current prices for these products are low. Then, as the demand for electricity grows, a waste-heat boiler and a steam turbine are additionally commissioned, which will increase not only the capacity, but also the efficiency of the station. Subsequently, when the demand for electricity increases again, it will be possible to build a coal gasification unit at the station.

The role of coal-fired thermal power plants is a key topic when it comes to preserving natural resources, protecting the environment and ways of developing the economy. These aspects of the problem at hand are not necessarily conflicting. The experience of using new technological processes of coal combustion shows that they can successfully and simultaneously solve problems of both environmental protection and reduce the cost of electricity. This principle was taken into account in a joint US-Canadian report on acid rain released last year. Guided by the proposals contained in the report, the US Congress is currently considering establishing a general national initiative to demonstrate and use "clean" coal combustion processes. The initiative, which will combine private capital with federal investment, aims to commercialize new coal combustion processes in the 1990s, including fluidized bed boilers and gas generators. However, even with the widespread use of new coal combustion processes in the near future, the growing demand for electricity cannot be satisfied without a whole set of coordinated measures to conserve electricity, regulate its consumption and increase the productivity of existing thermal power plants operating on traditional principles. Economic and environmental issues that are constantly on the agenda are likely to lead to completely new technological developments that are fundamentally different from those described here. In the future, coal-fired thermal power plants can turn into complex enterprises for the processing of natural resources. Such enterprises will process local fuels and other natural resources and produce electricity, heat and various products, taking into account the needs of the local economy. In addition to fluidized bed boilers and coal gasification plants, such plants will be equipped with electronic technical diagnostics and automated control systems and, in addition, it will be useful to use most of the by-products of coal combustion.

Thus, the opportunities for improving the economic and environmental factors of coal-based electricity production are very wide. The timely use of these opportunities depends, however, on the government's ability to implement balanced energy and environmental policies that create the necessary incentives for the electricity industry. It is necessary to take measures to ensure that new coal combustion processes are developed and implemented rationally, in cooperation with energy companies, and not as it was with the introduction of scrubber gas cleaning. All this can be achieved if costs and risks are minimized through well thought-out design, testing and improvement of small pilot plants, followed by widespread industrialization of the developed systems.

March 23rd, 2013

Once, when we drove into the glorious city of Cheboksary, from the east, my wife noticed two huge towers along the highway. "And what is it?" she asked. Since I absolutely didn’t want to show my wife my ignorance, I rummaged a little in my memory and gave out a victorious one: “This is a cooling tower, don’t you know?”. She was a little embarrassed: "What are they for?" "Well, something to cool there, it seems." "And what?". Then I was embarrassed, because I absolutely did not know how to get out further.

Maybe this question has remained forever unanswered in memory, but miracles do happen. A few months after this incident, I see a post in my friend feed z_alexey about the recruitment of bloggers wishing to visit the Cheboksary CHPP-2, the same one that we saw from the road. You have to drastically change all your plans, it will be unforgivable to miss such a chance!

So what is a CHP?

This is the heart of the CHP plant, and this is where the main action takes place. The gas that enters the boiler burns out, releasing a crazy amount of energy. "Pure Water" is also served here. After heating, it turns into steam, more precisely into superheated steam, which has an outlet temperature of 560 degrees and a pressure of 140 atmospheres. We will also call it "Pure Steam" because it is formed from prepared water.

In addition to steam, we also have an exhaust outlet. At maximum capacity, all five boilers consume almost 60 cubic meters of natural gas per second! To remove the combustion products, a non-childish "chimney" is needed. And this is also available.

The pipe can be seen from almost any area of the city, given the height of 250 meters. I suspect that this is the tallest building in Cheboksary.

There is a slightly smaller pipe nearby. Reserve again.

If a CHP plant is fired with coal, additional exhaust treatment is required. But in our case, this is not required, since natural gas is used as a fuel.

In the second section of the boiler and turbine shop, there are power generating units.

There are four of them installed in the engine room of Cheboksary CHPP-2, with a total capacity of 460 MW (megawatt). This is where the superheated steam from the boiler room is fed. He, under enormous pressure, is sent to the turbine blades, forcing a thirty-ton rotor to rotate at a speed of 3000 rpm.

The installation consists of two parts: the turbine itself, and a generator that generates electricity.

And here is what the turbine rotor looks like.

Gauges and gauges are everywhere.

Both turbines and boilers can be stopped instantly in the event of an emergency. For this, there are special valves that can shut off the supply of steam or fuel in a fraction of a second.

I wonder if there is such a thing as an industrial landscape, or an industrial portrait? There is beauty here.

There is a terrible noise in the room, and in order to hear a neighbor, you have to strain your hearing. Plus it's very hot. I would like to take off my helmet and undress to a T-shirt, but this cannot be done. For safety reasons, clothes with short sleeves are prohibited at the CHP, there are too many hot pipes.

Most of the time, the workshop is empty, people show up here once every two hours, during a round. And the equipment operation is controlled from the main control board (group control panels for boilers and turbines).

This is what the duty officer's workplace looks like.

There are hundreds of buttons around.

And dozens of sensors.

There are mechanical, there are electronic.

This is our excursion, and people are working.

In total, after the boiler and turbine shop, at the output we have electricity and steam that has partially cooled down and has lost some of its pressure. Electricity seems to be easier. The output voltage from different generators can be from 10 to 18 kV (kilovolts). With the help of block transformers, it rises to 110 kV, and then electricity can be transmitted over long distances using power lines (power lines).

It is unprofitable to let the remaining "pure steam" go to the side. Since it is formed from "Pure water", the production of which is a rather complicated and costly process, it is more expedient to cool it and return it back to the boiler. So in a vicious circle. But with its help, and with the help of heat exchangers, you can heat water or produce secondary steam, which can be easily sold to third-party consumers.

In general, it is in this way that we receive heat and electricity into our homes, having the usual comfort and coziness.

Oh yes. And what are cooling towers for?

It turns out everything is very simple. To cool the remaining "Pure steam", before the new supply to the boiler, all the same heat exchangers are used. It is cooled with the help of industrial water, at CHPP-2 it is taken directly from the Volga. It does not require any special training and can also be reused. After passing through the heat exchanger, the process water is heated and goes to the cooling towers. There it flows down in a thin film or falls down in the form of drops and is cooled due to the counterflow of air created by the fans. And in ejection cooling towers, water is sprayed using special nozzles. In any case, the main cooling occurs due to the evaporation of a small part of the water. The cooled water leaves the cooling towers through a special channel, after which, with the help of a pumping station, it is sent for reuse.

In a word, cooling towers are needed to cool the water that cools the steam operating in the boiler-turbine system.

All the work of the CHPP is controlled from the Main Control Board.

There is a duty officer at all times.

All events are logged.

Don't feed me bread, let me take a picture of the buttons and sensors ...

On this, almost everything. In conclusion, there are few photos of the station.

This is an old, no longer working pipe. Most likely it will be demolished soon.

There is a lot of agitation at the enterprise.

Here they are proud of their employees.

And their achievements.

It seems that it is not in vain ...

It remains to add that, as in a joke - "I do not know who these bloggers are, but their guide is the director of the branch in Mari El and Chuvashia of TGK-5 OJSC, IES holding - Dobrov S.V."

Together with the station director S.D. Stolyarov.

Without exaggeration, they are real professionals in their field.

And of course, many thanks to Irina Romanova, who represents the press service of the company, for a well-organized tour.

The principle of operation of a combined heat and power plant (CHP) is based on the unique property of water vapor - to be a heat carrier. In a heated state, under pressure, it turns into a powerful source of energy that drives the turbines of thermal power plants (TPPs) - a legacy of such a distant era of steam.

The first thermal power plant was built in New York City on Pearl Street (Manhattan) in 1882. The birthplace of the first Russian thermal station, a year later, became St. Petersburg. Strange as it may seem, but even in our age of high technologies, thermal power plants have not found a full-fledged replacement: their share in the global energy sector is more than 60%.

And there is a simple explanation for this, which contains the advantages and disadvantages of thermal energy. Its "blood" - fossil fuel - coal, fuel oil, oil shale, peat and natural gas are still relatively available, and their reserves are quite large.

The big disadvantage is that the products of fuel combustion cause serious harm to the environment. And the natural pantry will one day be completely depleted, and thousands of thermal power plants will turn into rusting "monuments" of our civilization.

Principle of operation

To begin with, it is worth deciding on the terms "CHP" and "TPP". In simple terms, they are sisters. "Clean" thermal power plant - TPP is designed exclusively for the production of electricity. Its other name is "condensing power plant" - IES.

Combined heat and power plant - CHP is a type of thermal power plant. In addition to generating electricity, it supplies hot water to the central heating system and for domestic needs.

The CHP plant's operation scheme is quite simple. Fuel and heated air - an oxidizing agent - enter the furnace at the same time. The most common fuel in Russian thermal power plants is crushed coal. The heat from the combustion of coal dust converts the water entering the boiler into steam, which is then fed under pressure to a steam turbine. A powerful stream of steam causes it to rotate, driving the generator rotor, which converts mechanical energy into electrical energy.

Further, the steam, which has already significantly lost its original parameters - temperature and pressure - enters the condenser, where after a cold "water shower" it again becomes water. Then the condensate pump transfers it to the regenerative heaters and then to the deaerator. There, the water is freed from gases - oxygen and CO 2, which can cause corrosion. After that, the water is reheated by steam and fed back to the boiler.

Heat supply

The second, no less important function of the CHP is to provide hot water (steam) intended for central heating systems in nearby settlements and for domestic use. In special heaters, cold water is heated to 70 degrees in summer and 120 degrees in winter, after which it is pumped into the common mixing chamber by network pumps and then flows through the heating main system to consumers. Water supplies at the CHPP are constantly replenished.

How TPPs work on gas

Compared to coal-fired CHPPs, TPPs where gas turbine units are installed are much more compact and environmentally friendly. Suffice it to say that such a station does not need a steam boiler. A gas turbine plant is essentially the same turbojet aircraft engine, where, unlike it, the jet stream is not emitted into the atmosphere, but rotates the generator rotor. At the same time, the emissions of combustion products are minimal.

New technologies for coal combustion

The efficiency of modern CHP plants is limited to 34%. The vast majority of thermal power plants still run on coal, which can be explained quite simply - the reserves of coal on Earth are still enormous, so the share of thermal power plants in the total volume of generated electricity is about 25%.

The process of burning coal has remained practically unchanged for many decades. However, new technologies also came here.

The peculiarity of this method is that, instead of air, pure oxygen released from the air is used as an oxidizing agent in the combustion of coal dust. As a result, a harmful impurity - NOx - is removed from the flue gases. The rest of the harmful impurities are filtered out in the process of several stages of purification. The remaining CO 2 at the outlet is pumped into containers under high pressure and must be buried at a depth of 1 km.

Oxyfuel capture method

Here, too, when burning coal, pure oxygen is used as an oxidizing agent. Only unlike the previous method, steam is generated at the moment of combustion, which drives the turbine into rotation. Then ash and sulfur oxides are removed from the flue gases, cooling and condensation are performed. The remaining carbon dioxide under a pressure of 70 atmospheres is converted into a liquid state and placed underground.

Pre-combustion method

Coal is burned in the "usual" mode - in a boiler mixed with air. After that ash and SO 2 - sulfur oxide are removed. Further, CO 2 is removed using a special liquid absorbent, after which it is disposed of by burial.

Five of the most powerful thermal power plants in the world

The championship belongs to the Chinese TPP Tuoketuo with a capacity of 6,600 MW (5 en / bl. X 1200 MW), occupying an area of 2.5 square meters. km. It is followed by her "compatriot" - Taichzhun TPP with a capacity of 5824 MW. The three leaders are closed by the largest in Russia Surgutskaya GRES-2 - 5597.1 MW. The fourth place is taken by the Polish Belchatuvskaya TPP - 5354 MW, and the fifth - Futtsu CCGT Power Plant (Japan) - a gas-fired TPP with a capacity of 5040 MW.

Until yesterday, in my mind, all coal-fired power plants were about the same and represented the ideal set of horror films. With structures blackened from time, boiler units, turbines, millions of different pipes and their cunning interweaving with a generous layer of black coal dust. Rare workers, more like miners, in the poor lighting of green gas lamps, are repairing some complex units, here and there, hissing, clouds of steam and smoke burst out, thick puddles of dark-colored slurries spilled on the floor, and something is dripping everywhere. This is how I saw coal stations and thought that their century was already leaving. Gas is the future, I thought.

It turns out not at all.

Yesterday I visited the newest coal-fired power unit at the Cherepetskaya GRES in the Tula Region. It turns out that modern coal stations are not grimy at all, and the smoke from their chimneys is neither thick nor black.

1. A few words about the principle of operation of the GRES... With the help of pumps, water, fuel and atmospheric air are supplied to the boiler under high pressure. The combustion process takes place in the boiler furnace - the chemical energy of the fuel is converted into heat. The water flows through a pipe system located inside the boiler.

2. Combustible fuel is a powerful source of heat, transferred to water, which is heated to boiling point and evaporated. The resulting steam in the same boiler is overheated above the boiling point, up to about 540 ° C, and under high pressure of 13–24 MPa is fed to the steam turbine through one or several pipelines.

3. The steam turbine, the generator and the exciter make up the whole turbine unit. In a steam turbine, steam expands to a very low pressure (about 20 times less than atmospheric pressure), and the potential energy of the compressed and heated to a high temperature steam is converted into kinetic energy of rotation of the turbine rotor. The turbine sets in motion an electric generator, which converts the kinetic energy of rotation of the generator rotor into electric current.

4. Water intake is carried out directly from the Cherepetsk reservoir.

5. Water undergoes chemical treatment and deep desalination so that deposits on the internal surfaces of equipment do not appear in steam boilers and turbines.

6. Coal and fuel oil are delivered to the station by rail.

7. In an open coal warehouse, loading cranes are unloading wagons. Then the big one comes into play, which is fed to the conveyor.

8. This is how the coal gets to the sections of the crushing plant for preliminary crushing of coal and subsequent pulverization. Coal is fed into the boiler itself in the form of a mixture of coal dust and air.

10. The boiler plant is located in the boiler room of the main building. The boiler itself is something brilliant. A huge complex mechanism as high as a 10-storey building.

14. You can walk through the labyrinths of the boiler plant forever. The time allotted for filming had run out twice, but it was impossible to tear yourself away from this industrial beauty!

16. Galleries, elevator shafts, walkways, stairs and bridges. In a word - space)

17. The sun's rays illuminated a tiny person against the background of everything that was happening, and I involuntarily thought that all these complex gigantic structures were invented and built by a person. Such a small man invented ten-story ovens to produce electricity on an industrial scale from a mineral.

18. Beauty!

19. Behind the wall from the boiler plant there is a turbine room with turbine generators. Another giant room, more spacious.

20. Yesterday, power unit No. 9 was inaugurated, which was the final stage of the Cherepetskaya GRES expansion project. The project included the construction of two modern coal-fired power units with a capacity of 225 MW each.

21. Guaranteed electric capacity of the new power unit - 225 MW;

Electrical efficiency - 37.2%;

Specific consumption of equivalent fuel for power generation is 330 gt / kW * h.

23. The main equipment includes two steam condensing turbines manufactured by OJSC Power Machines and two boiler units manufactured by OJSC EMAlliance. The main fuel of the new power unit is Kuznetsk coal of the DG grade.

24. Control room.

25. The power units are equipped with the first in the Russian market integrated dry dust-desulfurization system of flue gases with electrostatic filters.

26. Outdoor switchgear transformers.

28. The commissioning of the new power unit will make it possible to decommission outdated coal equipment of the first stage without reducing the volume of electricity generation and the total installed capacity of the station.

29. Together with the new power unit, two 87-meter cooling towers were built - part of the service water supply system, which supplies a large amount of cold water to cool the turbine condensers.

30. Seven spans of 12 meters. From below, such a height does not seem so serious.

31. At the top of the chimney, it was hot and cool at the same time. The camera was constantly fogging up.

32. View of the power unit from the cooling tower. The new power generating facilities of the station are designed in such a way as to significantly reduce emissions of pollutants, reduce dust emission when working in a coal warehouse, reduce the amount of water consumed, and also eliminate the possibility of environmental pollution by wastewater.

34. Inside the cooling tower, everything turned out to be quite simple and boring)

36. The photo clearly shows the new power unit and two old ones. How the chimney of the old power unit and the new one smokes. Gradually, the old power units will be decommissioned and dismantled. So it goes.