Types of NGV fuel, their advantages and disadvantages. Compressed Natural Gas Applications

Instructions

Liquefied natural gas(LNG) is a colorless, odorless liquid, consisting of 75-90% and possessing very important properties: in a liquid state it is not flammable, not aggressive, which is extremely important during transportation. LNG liquefaction process has a character, where each new stage means compression by 5-12 times, followed by cooling and transition to the next stage. The LNG becomes liquid at the end of the last stage of compression.

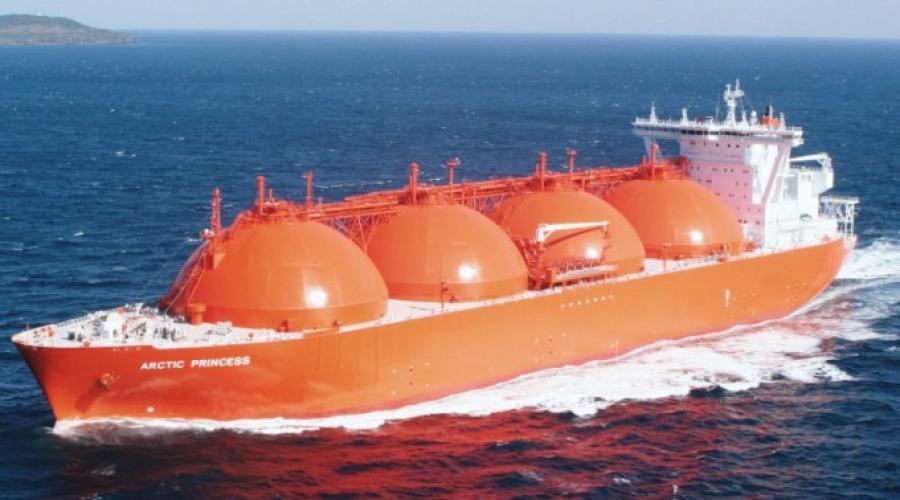

If gas needs to be transported over very long distances, then it is much more profitable to use special vessels - gas tankers. A pipeline is being extended from the gas site to the nearest suitable location on the sea coast, and a terminal is being built on the coast. There the gas is strongly compressed and cooled, turning into a liquid state, and pumped into isothermal tanks of tankers (at temperatures of about -150 ° C).

This method of transportation has a number of advantages over pipeline transportation. Firstly, one such in one flight can carry a huge amount of gas, because the density of a substance in a liquid state is much higher. Secondly, the main costs are not for transportation, but for the loading and unloading of the product. Thirdly, storage and transportation of liquefied gas is much safer than compressed gas. There is no doubt that the share of natural gas transported in liquefied form will steadily increase in comparison with gas pipeline supplies.

Liquefied natural gas in demand in various fields of human activity - in industry, in road transport, in medicine, in agriculture, in science, etc. gas We won due to the convenience of their use and transportation, as well as environmental friendliness and low cost.

Instructions

Before liquefying hydrocarbon gas and it must be pre-cleaned and water vapor removed. Carbonic gas removed using a three-stage molecular filter system. Purified in this way gas in small quantities it is used as a regeneration. Recoverable gas either burned or used to generate power in generators.

Drying takes place using 3 molecular filters. One filter absorbs water vapor. Another dries gas, which then passes through the third filter. To lower the temperature gas passed through a water cooler.

The nitrogen method involves the production of liquefied hydrocarbon gas and from any gas new sources. The advantages of this method include simplicity of technology, level of safety, flexibility, ease and low cost of operation. The limitations of this method are the need for a source of electricity and high capital costs.

With a mixed method for the production of liquefied gas and a mixture of nitrogen and is used as a refrigerant. Receive gas also from any sources. This method is characterized by flexibility in the production cycle and low variable production costs. When compared with the nitrogen liquefaction method, capital costs are more significant here. A source of electricity is also required.

Sources:

- What is gas liquefaction?

- Liquefied gas: receipt, storage and transportation

- what is liquefied gas

Natural gas is extracted from the bowels of the Earth. This mineral consists of a mixture of gaseous hydrocarbons, which is formed by the decomposition of organic matter in the sedimentary rocks of the earth's crust.

What substances are included in natural gas

80-98% of natural gas is (CH4). It is the physicochemical properties of methane that determine the characteristics of natural gas. Along with methane, natural gas contains compounds of the same structural type - ethane (C2H6), propane (C3H8), and butane (C4H10). In some cases, in small amounts, from 0.5 to 1%, natural gas contains: (C5H12), (C6H14), heptane (C7H16), (C8H18) and nonane (C9H20).

Natural gas also includes compounds of hydrogen sulfide (H2S), carbon dioxide (CO2), nitrogen (N2), helium (He), water vapor. The composition of natural gas depends on the characteristics of the fields where it is produced. Natural gas produced in purely gas fields consists mainly of methane.

Characteristics of the constituents of natural gas

All chemical compounds that make up natural gas have a number of properties that are useful in various industries and in everyday life.

Methane is a flammable gas, colorless and odorless; it is lighter than air. It is used in industry and everyday life as a fuel. Ethane is a colorless and odorless flammable gas, slightly heavier than air. Basically, ethylene is obtained from. Propane is a colorless and odorless poisonous gas. Its properties are close to butane. Propane is used, for example, in welding, in the processing of scrap metal. Lighters and gas cylinders are filled with liquefied and butane gas. Butane is used in refrigeration plants.

Pentane, hexane, heptane, octane and nonane -. Pentane is found in small quantities in motor fuels. Hexane is also used in the extraction of vegetable oils. Heptane, hexane, octane and nonane are good organic solvents.

Hydrogen sulfide is a poisonous colorless heavy gas of rotten eggs. This gas, even in small concentrations, causes paralysis of the olfactory nerve. But due to the fact that hydrogen sulfide has good antiseptic properties, it is used in small doses in medicine for hydrogen sulfide baths.

Carbon dioxide is a non-flammable, odorless, odorless gas with a sour taste. Carbon dioxide is used in the food industry: in the production of carbonated drinks to saturate them with carbon dioxide, for freezing food, for cooling goods during transportation, etc.

Nitrogen is a harmless colorless gas, tasteless and odorless. It is used in the production of mineral fertilizers, used in medicine, etc.

Helium is one of the lightest gases. It is colorless and odorless, does not burn, and is not toxic. Helium is used in various fields of industry - for cooling nuclear reactors, filling stratospheric balloons.

GAS COMPRESSION

GAS COMPRESSION, a reduction in the volume of gas achieved by applying external pressure to it. Some gases, including carbon dioxide, can be converted to liquid by compression at room temperature. Other gases must be pre-cooled in order to be converted to liquid under pressure. The highest temperature at which a gas can be turned into a liquid by applying pressure to it is called the critical temperature.

.

See what "GAS COMPRESSION" is in other dictionaries:

COMPRESSION, a decrease in the volume of a substance by forcibly enclosing it in a small volume of space (for example, when compressing a gas) or limiting the expansion of a heated substance (as when cooking in a pressure cooker). This process… … Scientific and technical encyclopedic dictionary

Compression, compression (from the Latin compressio): There is an article "compression" in Wiktionary ... Wikipedia

- (a. gas cooling; n. Gasabkuhlung; Gaskuhlung; f. refroidissement du gaz; and. refrigeracion de gas, enfriamiento de gas) lowering the temperature of the pumped gas at gas collection points and compressor stations of main gas pipelines, ... ... Geological encyclopedia

- (shock wave), a thin transition region propagating at a supersonic speed, in the swarm there is a sharp increase in density, pressure and velocity in VA. W. in. occur during explosions, detonation, during supersonic movements of bodies, during ... ... Physical encyclopedia

Thermal processes The article is part of the same name ... Wikipedia

Conversion to wa from a gaseous state to a liquid state. S. of the city is possible only when the rate pax is less than the critical temperature. In the industry of S. g. With critical. temperature higher than the ambient temperature (practically above 50 ° С) is carried out by gas compression in ... ... Big Encyclopedic Polytechnic Dictionary

Natural gas- (Natural gas) Natural gas is one of the most common energy sources Gas definition and application, physical and chemical properties of natural gas Contents >>>>>>>>>>>>>>> ... Investor encyclopedia

AND; f. [from lat. compressio compression] 1. Tech. Compression of air, gas or a combustible mixture under pressure in an engine cylinder. 2. Reducing the amount of writing without prejudice to its content. Perform the necessary compression of the article text. * * * ... ... encyclopedic Dictionary

- (Latin compressio compression) compression of gas in the engine cylinder, air in the compressor. New dictionary of foreign words. by EdwART, 2009. compression [lat. compressio] - compression; compression of gas in the engine cylinder. A large dictionary of foreign words. ... ... Dictionary of foreign words of the Russian language

GOST 28567-90: Compressors. Terms and Definitions- Terminology GOST 28567 90: Compressors. Terms and definitions original document: Hubkolbenverdichter oder Membranverdichter, Lage der Zylinder oder Membran rechtwinklig zueinander (Winkelbauart) 68 Definitions of the term from different documents: ... ... Dictionary-reference book of terms of normative and technical documentation

Books

- , Romanenko Svetlana Valentinovna. The publication presents the material of the basic course of lectures on the discipline Resistance of materials, read during two semesters at the Russian State University of Oil and Gas (NRU) named after V.I. I. M. Gubkina. Considered ...

- Strength of materials. Study guide, S. V. Romanenko. The publication presents the material of the basic course of lectures on the discipline "Resistance of Materials", read for two semesters at the Russian State University of Oil and Gas (NRU) named after V.I. I. M. Gubkina. Considered ...

The base of natural gas, which is of natural (natural) origin, is methane (CH4). Natural gas was formed through organic transformation. The methane content in natural gas can range from 91 to 99%, everything else is propane, ethane, butane, and nitrogen. This variation in percentage is explained by the difference in the chemical composition of gas produced in different parts of our Earth. However, when burnt, natural gas of different origins gives off the same amount of heat, which makes geo-referencing absolutely unimportant for both you and your engine. Thanks to electronic sensors of LPG equipment, the composition of the gas is automatically determined, after which the proportion of the fuel mixture is adjusted, taking into account the characteristics of this gas.

Benefits of natural gas

The chemical composition of natural gas has a beneficial effect on the condition of the engine and does not entail problems associated with operation. Due to the absence of additives in the methane composition, which are present in liquefied hydrocarbon gases ( LPG), the combustion products of natural gas do not contain harmful impurities. Moreover, when natural gas is burned, CO2 emissions are reduced by 25%.

The amount of methane in natural gas is like the octane number for gasoline, according to this parameter it is customary to characterize natural gas... What does this mean for the engine? The operation of the engine, as well as the likelihood of such a phenomenon as detonation, depends on this parameter.

Compressed natural gas(LNG) has a number of undeniable advantages over liquefied petroleum gas (LPG), including environmental friendliness and safety. Methane, which, as you already know, is the most abundant in natural gas, it dissolves quickly in the air, which practically negates the possibility of the gas igniting in the event of damage. The way natural gas is stored minimizes the likelihood of an uncontrolled leak. Serviceable cylinders are required to withstand burst pressure of more than 600 bar, and thanks to the valve system, a controlled gas supply occurs.

When running on CNG, the engine can demonstrate high performance due to its high octane number (~ 130), especially when the engine is equipped with a turbine or exhaust gas recirculation system, or better both together. Although this has a downside, for example, high gas consumption, as well as problems with heat transfer. The engine noise level during operation on natural gas is reduced by 3 dB, therefore this type of fuel is very relevant for public transport. Compressed natural gas, like CIS can be used both on gasoline and, although in the case of diesels, you will have to face a low return on investment. The problem is that a diesel engine will need to be fitted with a spark ignition system or a mixed cycle in which the diesel will act as an igniter.

There are also disadvantages to this type of fuel.

1. Low energy density. Because of this feature, natural gas is very often used in a compressed form. The pressure or compression ratio is 20 MPa or 200 bar. In terms of energy density, we get 7 kJ / dm3, in comparison with gasoline in which this figure is 30 kJ / dm3 can be obtained without any additional compression operations. This feature of natural gas leads to the fact that the engine, in order to run on this fuel, must be optimized for this, and at the same time it will be significantly higher. With equal sizes of gas (LPG and LNG), more can be traveled on LPG, therefore, in order to compensate for the low performance, those who want use methane as an alternative fuel, you have to put more gas tanks on your cars. As you understand, this leads to an increase in the total weight of the car, and a decrease in free space in the trunk. The high pressure required to store LNG-filled tanks (usually cylindrical or round) makes the tanks very bulky and, in the case of light vehicles, take up a lot of space.

There are two types of systems capable of operating on natural gas - monovalent and bivalent.

- Monovalent the type provides for the combustion of exclusively LNG, which comes from a special tank.

- Bivalent type provides for the simultaneous use of gas together with the main fuel, due to which there is a saving of money and a decrease in gasoline consumption.

Natural gas consists mainly of methane (at least 90%) with minor impurities of ethane (up to 6%), propane (up to 1.7%), and butane (up to 1%).

Methane is a colorless and odorless gas, slightly soluble in water, lighter than air. It belongs to saturated hydrocarbons, the molecules of which consist only of carbon and hydrogen. The high hydrogen content provides a more complete combustion of fuel in the engine cylinders compared to gasoline and LPG, therefore methane is a full-fledged fuel for cars with good anti-knock characteristics.

Characterization of methane.

Molecular Formula - CH 4

Molar mass, kg / mol - 16.03

Density at a temperature of 15 ° C and a pressure of 0.1 MPa:

- in a gaseous state, kg / m 3 - 0.717

- in liquid state, kg / l - 0.42

Carbon number - 2.96

Boiling point, ° С - -161.7

Autoignition temperature (flash), ° С - 590

Net calorific value:

- in a gaseous state, kJ / m 3 - 33800

- in liquid state, kJ / l - 20900

Relative density (air) - 0.554

Corrosive activity - absent

Toxicity - non-toxic

Combustion temperature, ° С - 2030

For reference . Heat of combustion.

Heat of combustion- the amount of heat released during the complete combustion of 1m 3 of gas, at atmospheric pressure and a temperature of 20 ° C.

There is a higher and lower heat of combustion of gas. When determining the gross calorific value, all the heat released during combustion and removed from the combustion products by cooling them to the initial temperature is taken into account. In practice, the formed water vapors do not condense and carry away part of the heat spent on heating 1 kg of water from 0 to 100 ° C, which is 418.6 kJ.

During combustion, heat is expended on the evaporation of moisture contained in the fuel and obtained from the combustion of hydrogen. Therefore, for the characterization of gaseous fuels, in practice, the net calorific value of the gas is used, which is a standard value.

Before being used as a motor fuel, natural gas undergoes preliminary preparation to ensure that its parameters correspond to engine performance (removal of impurities) and storage conditions on a vehicle.

Since natural gas liquefies at a temperature of -161.7 ° C, and under normal conditions this cannot be done, it is stored on cars in cylinders compressed to 20 MPa (200 kg / cm2).

Compressed gases are characterized by the fact that at a temperature of 20 ° C and high pressure (20 MPa) they remain in a gaseous state.

Compressed natural fuel gas (compressed natural gas).

In terms of physical and chemical parameters and the content of impurities, natural fuel gas must comply with GOST 27577-2000 "Compressed natural fuel gas for internal combustion engines".

In terms of physical and chemical parameters, gas according to this GOST must comply with the requirements and standards given in Table 1.

Table 1.

| №№ п / п | Indicators | Meaning |

| 1 | 2 | 3 |

| 1. | Low volumetric heat of combustion, kJ / m 3, not less | 31800 |

| 2. | Relative density to air | 0,55-0,70 |

| 3. | Calculated octane number (by the motor method), not less | 105 |

| 4. | Hydrogen sulfide concentration, g / m 3, no more | 0,02 |

| 5. | Mercaptan sulfur concentration, g / m 3, no more | 0,036 |

| 6. | The mass of mechanical impurities in 1m 3, mg, no more | 1,0 |

| 7. | Total volume fraction of non-combustible components,%, no more | 7,0 |

| 8. | Oxygen volume fraction,%, no more | 1,0 |

| 9. | Water vapor concentration, mg / m 3, no more | 9,0 |

Disadvantages and advantages of using compressed natural gas versus gasoline.

1. Disadvantages.

1.1. The high-pressure gas content requires the use of high-strength cylinders with a significant mass and made of high quality steels. The weight of one cylinder with a capacity of 50 liters with 10m 3 of gas is about 70 kg. Installation of gas cylinders on a car entails a decrease in the carrying capacity of the car by 10-12%, and the vehicle's power reserve also decreases.

CNG cylinders are high-pressure vessels, for alloy steel cylinders the test period is set once every 5 years, and for carbon steel cylinders - once every 3 years.

1.2. Since the heat of combustion of a gas-air mixture of methane is less than the heat of combustion of a gas-air mixture (3.22 MJ / m 3 for methane with air and 3.55 MJ / m 3 for gasoline with air), and due to a lower cylinder filling factor, the engine power when converted to compressed gas is reduced by 18-20%.

1.3. When using gas fuel, it is difficult to start the engine in winter at temperatures below 15 ° C. The reason is a higher ignition temperature of the gas-air mixture and a lower flame propagation speed.

1.4. For maintenance and repair of gas-cylinder vehicles, a higher qualification of service personnel is required. Compared to the maintenance of gasoline and diesel engines, the labor intensity of maintenance and repair of gas equipment increases by 13-15%, and costs - by 4-6%.

1.5. The operation of engines on compressed gas is accompanied by a deterioration in the traction, dynamic and operational characteristics of vehicles: the acceleration time increases by 25-30%; the maximum speed is reduced by 5-7%.

2. Benefits.

2.1. Gas fuel burns more completely in the cylinders of engines due to the wider ignition limits of gas in comparison with gasoline. If the ignition limits of gasoline mixed with air are 6.0 and 1.5%, respectively, then the ignition limits of compressed gas mixed with air are 15% at the upper limit and 5% at the lower limit. This makes it possible to deplete the combustible mixture to α = 1.2-1.3 in the operating modes of the engines.

As a result, the toxicity of exhaust gases is significantly reduced (in terms of carbon oxides - by 2-3 times, in terms of nitrogen oxides - by 1.2-2.0 times, in terms of hydrocarbons - by 1.1-1.4 times).

2.2. Compressed gas does not dilute the oil in the engine crankcase, does not wash oil from the cylinder walls, and does not thereby worsen the lubrication conditions. Therefore, the wear of parts of engines running on gas is lower than that of gasoline engines. As a result, the service life of the engines increases by 1.3-1.5 times. The service life of the oil is also increased by 1.5-2 times, and the costs for it are reduced by 25-35 percent.

2.3. Compressed gas prices are lower than petrol: The savings in fuel costs exist despite the loss of engine power and reduced vehicle payload.

Avtotrans-consultant.ru.

The use of gas as a vehicle fuel began more than 150 years ago, when the Belgian Etienne Lenoir created an internal combustion engine powered by lamp gas. This type of fuel has not received much popularity. The subsequent growth in oil production and the reduction in the price of its refined products, as well as the creation of more advanced engines, made gasoline the leader in the fuel market. Interest in NGV fuel arose again in the first half of the 20th century.

In Russia, this direction began to develop since the 30s, when, due to a shortage of oil with a rapidly developing industry, the government decided to transfer part of the transport to gas. The corresponding decree was issued in 1936.

The production of equipment was set up, gas stations were opened, the development of gas engines began, and both types of gas were used - compressed and hydrocarbon. The full-scale implementation of the program was prevented by the Great Patriotic War. Nevertheless, they did not abandon the plan: already in peacetime, new gas-cylinder vehicles were designed and put into production, the number of which reached 40 thousand. Dozens of gas filling stations were built for them.

When were the largest hydrocarbon reserves in Western Siberia and the country

entered the era of oil abundance, attention to the program for the creation of gas-cylinder transport waned, although work continued. In the 1980s, they started talking seriously about saving money, and gas again took revenge. By 1985, three resolutions of the Council of Ministers were issued on the massive transfer of large fuel consumers to gas. Over the next five years, about 500 automobile gas filling compressor stations were built, up to 0.5 million vehicles were converted to CNG. The work was coordinated by the interdepartmental council under the Ministry of the Gas Industry, chaired by Viktor Chernomyrdin.

The privatization that began in the 90s led to the disappearance of large auto enterprises; a significant part of municipal transport passed into private hands. And although at the same time a drop in oil production was noted (from 624 million tons in 1988 to 281 million tons in 1997), there was no shortage of oil products due to the reduction in the number of consumers.

As a result, gasoline and diesel fuel retained their market positions. A new upsurge in the NGV market in Russia began in 1998, when the demand for propane-butane mixture sharply increased.

Gas as a motor fuel is represented by two main types - compressed natural gas (CNG), which is supplied to special filling stations - CNG filling stations - through gas pipelines, and liquefied petroleum gas (LPG). The first is methane, and the second is a mixture of propane and butane, a product of associated petroleum gas (APG) processing. Historically, propane-butane was the first to spread. Its advantage is that it easily liquefies at ordinary temperatures at a pressure of only 10-15 atmospheres. At the same time, a steel cylinder with a wall thickness of only 4-5 mm is sufficient for its transportation. Methane is more difficult. It can be liquefied only at low temperatures, of the order of minus 160 degrees Celsius. Appropriate liquefaction and liquefaction technologies are not cheap. Methane can also be compressed. However, in order for the amount of compressed gas by volume to be at least approximately comparable to the liquefied propane-butane mixture, it must be compressed to 200-250 atmospheres. Therefore, much stronger and heavier cylinders are needed to transport compressed methane. Methane plants also have higher safety requirements. Therefore, propane equipment is most often installed on cars.

Compressed natural gas consumption (as opposed to LPG) is measured not in liters, but in filling meters. Since CNG is mainly composed of methane, its mass calorific value is 49.4 MJ / kg, which is 9% higher than that of gasoline and 11% higher than that of jet fuel1. For the consumer, if he switches from traditional fuel to LPG, the cost of fuel and lubricants is reduced by 20-25%. In turn, compressed natural gas also has an advantage over hydrocarbon gas. Energy efficiency of LPG is about 25% less than that of CNG - 6175 kcal / m3. cub. and 8280 kcal / m. cub. respectively. For the consumer, this means that 25-30% more liquefied petroleum gas will be required for the same distance, besides, it is slightly inferior to CNG in terms of environmental parameters2.

At the same time, the cost of NGV fuel does not exceed 50% of the cost of A-80 gasoline. According to the National Gas Engine Association, 3 the highest price for motor fuel is at hydrogen. It is 9.01 euros / liter. This is almost nine times more expensive than biodiesel (€ 1.11 / l) and gasoline (€ 0.66 / l). In turn, the cost of 1 m³ of gas, which is equivalent to 1 liter of gasoline, is more than twice cheaper than gasoline: the cost of 1 m³ of liquefied petroleum gas is 0.39 euros / l, compressed natural gas - 0.21 euros / l.

Environmental problems are a significant factor stimulating the states of the world community to develop the GMT market. The contribution of vehicles to air pollution in large cities and agglomerations ranges from 50 to 90% for all types of pollution. Therefore, the requirements for reducing the toxicity of exhaust gases from internal combustion engines of vehicles are constantly increasing - Euro-4 and Euro-5 standards are being introduced. Meanwhile, the conversion of cars to natural gas fuel reduces emissions of carbon dioxide (the main greenhouse gas) by 13%, nitrogen oxides - by 15-20%, 8-10 times reduces the smoke of exhaust gases and completely eliminates emissions of lead compounds. According to the Ministry of Energy of Russia, if we take Euro-4 quality gasoline as a standard, it turns out that CNG wins almost three times in terms of nitrogen oxide emissions, 14 times for CH, more than 16 times for benzopyrene, and more than 16 times for soot. 3 times (in comparison with diesel fuel - 100 times). Consequently, compressed natural gas is second only to electricity in terms of emissions of harmful substances into the atmosphere. Although LPG lags a little behind in terms of environmental parameters, it allows solving the problem of utilization of associated petroleum gas, which is still being flared, although in January 2009 a decree was signed “On measures to stimulate the reduction of atmospheric air pollution by products of associated petroleum gas combustion in flares. installations ".

According to experts, the future belongs to methane: propane-butane, like oil, is too valuable a raw material to be used as a vehicle fuel. Although it is, of course, much more convenient, and so far the fleet using it is larger: by the beginning of 2011, the number of LPG-powered vehicles in the world exceeded 15 million, and on CNG - 12 million. The annual turnover of propane-butane is 34 million tons of standard fuel, and of compressed gas - about 23 million tons.

Another advantage that a company that operates machines on methane gets is an increase in the level of safety, since by its physical and chemical properties natural gas is less hazardous than propane.

Also, thanks to the use of natural gas as a fuel, the service life of the oil and the internal combustion engine itself is increased. When the engine is running on gas fuel, the oil film is not washed off from the walls of the cylinder block, in addition, carbon deposits do not form on the cylinder head, piston rings do not coke, due to which wear of the internal combustion engine elements occurs, and its overhaul mileage increases by one and a half to two times. In addition, the performance of the ignition system is improved - the service life of the spark plugs is increased by 40% 5. All this reduces repair costs.

In addition, the CNG segment is the most resistant to the crisis in the Russian economy and the most dynamic in the medium term. In 2009, due to the decline in business activity during the crisis, the Russian CNG market decreased by 1.1%, while the consumption of gasoline and propane-butane decreased by 18% and 4%, respectively6.

The flip side of the coin of using gas as fuel is the possible unevenness of the engine. This is due to resonance in the intake system and stratification of the gas-air mixture. Starting a cold internal combustion engine in winter also becomes more difficult. This is due to the higher ignition temperature of the gaseous fuel and the lower combustion rate.

Also, a certain difficulty is the re-equipment of the car. The price of propane-butane equipment ranges from 15-28 thousand rubles, and methane equipment starts from 40 thousand rubles. At the same time, the mass of the kit exceeds 50 kg for LPG and more than 100 kg for CNG. Proceeding from this, the "specialization" of gases is being built: LPG - for light vehicles, and CNG - for heavy equipment. The most expensive and "weighty" part is the balloon. To reduce its weight and increase the strength of the walls, alloyed metals or aluminum reinforced with fiberglass are used; metal-composite cylinders are also installed in a basalt cocoon. In some branches of technology, reinforced plastic vessels are used, which are very expensive, but at the same time they are 4-4.5 times lighter than steel ones.

Thus, depending on the number of compressed gas cylinders, the mass of the truck increases by 400 -900 kg. At the same time, its carrying capacity decreases and fuel consumption increases, however, when using cylinders made of composite materials, this disadvantage does not significantly affect the useful characteristics of the car.

In summary, the main positive and negative aspects of using gas as a motor fuel include:

Main pluses:

Low cost;

Increased level of security;

Reduced level of emissions of harmful substances into the atmosphere;

Increased oil life;

Extending the engine wear-out period;

Reducing the calorific value of the gas-air mixture.

The main cons:

Possible unevenness of the engine;

Complication of starting a cold engine in frost;

Deterioration of the dynamic characteristics of the car;

Increase in the weight of the machine and decrease in its carrying capacity;

Increased labor intensity of engine maintenance and repair.

But the main disadvantage, which officials and car manufacturers say, especially in Russia, is the underdevelopment of the filling station network. In fact, this market has not yet been formed in Russia. There are about 22,000 ordinary gas stations in the country. That is, the CNG stations are 160 times smaller, and they are distributed very unevenly throughout the country. The global compressed natural gas market is characterized by a significant increase in consumption and advanced infrastructure development. The consumption of compressed natural gas in the world in 2005-2009 increased by 42%, and the number of CNG filling stations increased by more than 85% 7. To this end, the states are taking a number of measures to develop CNG filling station networks.

Measures to stimulate the development of CNG filling station networks

Iran and EU countries | Exemption of imported gas filling and gas-using equipment for natural gas from import customs duties. |

A ban on the construction of gas stations without a block for filling cars with compressed natural gas. |

|

Allocation of grants and subsidies for the construction of CNG filling stations. |

|

Exemption for a certain period from paying land tax during the construction of a CNG filling station. Decrease in property tax during the construction of CNG filling stations. |

|

Reducing the base for calculating property tax by a certain percentage of the cost of CNG filling stations and compressed natural gas vehicles. |

While the retail trade of LPG in Russia is developed by large players such as Gazenergoseti, LUKOIL and TNK-BP and many small companies, the CNG business is almost 90% occupied by Gazprom, which owns more than 200 CNG filling stations.

The shortage of gas filling stations and service points for gas-cylinder vehicles in Russia (238 stations and 74 points throughout the country) restrains the desire of vehicle owners to switch to alternative fuels. The fleet of vehicles operating at GMT in the accessibility zone of existing automobile gas filling compressor stations is significantly lower than the optimal one (in world practice, there are 500 units of transport equipment per CNG station). In addition, a limiting factor is the lack of government programs stimulating the development of the NGV business by providing subsidies for the purchase of LPG equipment, various tax incentives both in the CNG filling station sector and for consumers of motor fuel.

Along with this, there are certain difficulties arising during the construction of gas filling stations in urban development, associated with the length of time for the allocation and registration of land plots for construction, as well as with a number of provisions of the Fire Safety Standards (NPB III-98) directly related to CNG filling stations and their individual systems. Despite the criticism of NPB III-98 from interested organizations, they are the basic document for the fire brigade, coordinating the design documentation for the facilities for the production of GMT.

The above is essentially a brake on the development of a gas filling network in Russia. As a result, Russia, which occupied in 1986-1990. in terms of production and sales of CNG, the first place in the world (more than 1.2 billion m3 (3) per year), fell behind developed and even some developing countries.

In Russia, the requirements for gas filling stations are not separated into a separate regulatory document. In the design and construction of gas engine business facilities, a fairly significant number of state standards, building codes and regulations, environmental standards, fire safety standards and other documents are taken into account. This emphasizes the need to develop design standards for gas filling stations, including those in multi-fuel stations. Gazprom's enterprises have the CNG Station Maintenance Regulations, introduced in 2003. The quality of CNG supplied to the consumer is regulated by the State Standard, in effect since 2000, which establishes such important indicators as the volumetric calorific value, moisture content, sulfur content and mechanical impurities, filling pressure. Work is underway to bring the State standard in line with the European ISO standard for natural gas motor fuel, which in the long term should ensure the possibility of unhindered movement of gas vehicles (NGV) throughout Eurasia. At this time, the development of the State standard for the quality of liquefied natural gas is underway to replace the Technical conditions of 1987.

The requirements for gas-fuel equipment on vehicles are quite clearly stated in the relevant UNECE (United Nations Economic Commission for Europe) Regulations. The Technical Regulations "On the Safety of Wheeled Vehicles" provide for compliance with the requirements of the UNECE Regulations in Russia.

However, despite numerous talks about the profitability of the acquisition of so-called green cars, which include cars that run, including gas, according to the consulting company Frost & Sullivan, on this moment only 13% of consumers buy such cars. However, by 2015, experts predict an increase in this share to 30%. Thus, the total vehicle fleet in four years should amount to 80 million, of which 53 - 55% will fall on gas vehicles8.

According to Frost & Sullivan.

The popularity of compressed natural gas and propane-butane by the geography of its distribution. Thus, the traditionally strong markets of India, Iran and Pakistan have significant volumes of equipment sales and are expected to become 3L1074 leading countries in terms of the number of vehicles running on compressed natural gas methane and propane-butane. Compressed natural gas, methane, is still the most popular in Latin American countries. Propane-butane maintains a dominant position in Russia and the European Union.

Gas vehicles in 2010

Gas-cylinder vehicles (GBA). |

|

Pakistan | |

Argentina | |

Brazil | |

Colombia | |

Bangladesh | |

According to the forecast of Frost & Sullivan experts, in the near future these types of fuels will become even more popular: sales of such vehicles are expected to quadruple by 2015.

Total sales of propane-butane and compressed natural gas vehicles in

2009 - 2015, thousand units

According to Frost & Sullivan

The readiness of the Russian industry to implement a project to increase the level of consumption of natural gas as a motor fuel is still controversially assessed. The presence of gas transmission systems and gas distribution stations in Russia is adjacent to an extremely limited arsenal of new gas equipment, cylinders themselves and new automobile gas storage compressor stations.

All over the world, the development of the NGV business is ensured by the state with the support of large oil and gas companies - over 85 car models are produced that can run on natural gas. For example, Pakistan has organized the production of methane cars, buses and rickshaws. But in Russia, the choice is limited:

only Kamaz trucks and Nefaz buses (a subsidiary of Kamaz), as well as LiAZ, PAZ and KavZ (Russian Machines group) are serially produced.

According to the NP National Gas Engine Association, out of 40 million vehicles operated in Russia in 2010 (of which 80.8% were passenger cars, 16.5% were trucks, including special equipment, and 2.7% were for buses), the volume of the park of gas-cylinder vehicles running on compressed natural gas is about 100 thousand vehicles (of which 26.1% are cars, 50.5% are trucks, 23.3% are buses). Thus, almost three quarters of gas vehicles are trucks, buses and special vehicles.

The structure of the CNG fleet is as follows: for buses and trucks of categories M1 and N1 (vehicles used to transport passengers and having, in addition to the driver's seat, no more than eight seats, as well as vehicles intended for the carriage of goods with a maximum mass of not more than 3.5 t) accounts for 49.5%, passenger cars of category M1 - 23.3%, special equipment - 13.4%, trucks of categories N2 and N3 (vehicles intended for the carriage of goods having a maximum mass over 3.5 tons, but not more than 12 tons, and vehicles intended for the carriage of goods having a maximum mass of more than 12 tons) - 12.4%, buses of categories M2 and M3 (vehicles used for the carriage of passengers, having in addition to the driver's seat, more than eight seats, the maximum mass of which does not exceed 5 tons, and vehicles used for the carriage of passengers, having, in addition to the driver's seat, more than eight seats for sitting, the maximum weight of which exceeds 5 tons) - 1.4%, tractors - 0.05%.

According to the optimistic forecast of the NP National Gas Engine Association, the overall development dynamics of the fleet of cars by 2020 will amount to 58.5 million units, by 2030 - 85.4, according to the pessimistic - in 2020 - 38.6 million, by 2030 - 51.3. At the same time, the forecast for the consumption of motor fuel in Russia is as follows: the share of gaseous types of motor fuel in the total balance by 2030 will amount to 3% each for compressed natural gas and for liquefied petroleum gas. According to the results of 2010, the level of consumption of compressed natural gas amounted to 4 million tons, by 2020 it should reach 20 million tons, in 2030 - 51 million tons. The level of use of liquefied petroleum gas in 2010 was 15 million tons. tons, by 2020 will reach 30 million, in 2030 - 67 million tons.

Production program for main components (for compressed

natural gas)

Project periods Indicators | 2011 -2015 | 2016 - 2020 | 2021 - 2025 | 2026 - 2030 | Total |

Compressed natural gas consumption, million m³ | |||||

New GBA, thous. | |||||

New cylinders (equivalent 50 l), thous. | |||||

New CNG filling stations |

According to NP "National Gas Engine Association"

Rail transport is one of the largest consumers of motor fuel. The share of diesel fuel consumption by Russian Railways is 9.1% of the total consumption in the country (3.2 million tons). Now, Russian Railways has been tasked with replacing 30% of diesel fuel consumed by autonomous locomotives with natural gas by 20309. To solve it, more than 1 million tons of natural gas will be required per year. But the benefits will be tangible. For example, the indicators of harmful emissions recorded during testing and operation of gas turbine locomotives developed jointly with Gazprom VNIIGAZ turned out to be five times lower than the safety requirements of the European Union put forward by 2012, and the external noise did not exceed the sanitary standards of the Russian Federation.

Today, two shunting gas locomotives TEM18G are in trial operation on the Moscow and Sverdlovsk railways. In addition, at the Experimental Ring of the All-Russian Scientific Research Institute of Railway Transport (VNIIZhT) in Shcherbinka near Moscow, tests of the ChMEZG gas locomotive were carried out, which showed that the optimal share of replacing diesel fuel with natural gas ranges from 35 to 50%, depending on the type of shunting operations. At the same time, there is a decrease in emissions of toxic combustion products by about 1.5 - 2 times10. A program for the modernization of gas-fired locomotives has already been prepared, which should increase their reliability and efficiency, as well as increase the share of diesel fuel replacement up to 60%.

Back in December 2006, Russian Railways and the Samara Scientific and Technical Complex named after N.D. Kuznetsov signed an agreement on the joint creation of a new type of gas locomotive - a gas turbine locomotive. By that time, the Institute's specialists had already developed the NK-361 gas turbine engine and the power unit of the traction section. The project of the gas turbine locomotive itself was proposed by scientists from the All-Russian Research and Development Institute of Rolling Stock (VNIKTI), and the prototype was assembled at the Voronezh Locomotive Repair Plant. In one of the sections of the locomotive there is a fuel tank for 17 tons. One filling is enough for 750 km of travel. In June 2009, Russian Railways received a diploma from the Russian Book of Records for the development of this most powerful (8300 kW) gas turbine locomotive. In January 2010, for the first time in the world, he carried a freight train weighing 15 thousand tons (159 wagons). No modern locomotive is capable of such records.

A similar transition to natural gas as a motor fuel for diesel locomotives is also being carried out in the USA, Canada, Germany and Austria. In particular, a main gas-fired locomotive GE 3000 with a capacity of 2,200 kW was built in Austria.

NGV fuel also penetrates into aviation. Thus, the Airbus A-340-600, owned by Qatar Airways (Qatar), powered by Rolls-Royce engines, made a passenger flight on the London-Doha route. The aircraft was fueled with Shell-made fuel, which consists of aviation kerosene and liquid gas in a one-to-one ratio. In addition, Deputy Prime Minister of Qatar Abdullah bin Hamad al-Attiyah was present at the launch of the experimental production of gas kerosene using Gas to Liquids (GTL) technology. According to preliminary data, with the transition to gas kerosene, the world's airlines will be able to save $ 4 billion a year.

It is noteworthy that the first domestic helicopter capable of operating on gas (gas-powered aircraft) was created and tested back in 1987. It was a modified production machine of the Mi-8 family with an engine from the plant named after V.I. V.Ya. Klimov. This helicopter is being produced to this day. In addition, studies have shown that almost all aircraft with gas turbine engines can operate on gas fuel (all helicopters of the Mi-8 family, including the Mi-38, and regional aviation aircraft - Il-114, Yak-40, Tu-136, etc.) .P.). But so far there is only one copy of the airplane - Mi8GT - shown at the International Aviation and Space Salon back in 1995.

Therefore, in order for the Russian market to develop, state support is needed for machine builders and buyers of equipment. At present, various state programs are already operating around the world. On December 12, 2001, the UN Energy Commission adopted a resolution providing for the transfer of 23% of the car park of European countries to alternative types of motor fuels by 2020, including 10% (23.5 million units) - to natural gas, 8% ( 18.8 million) - for biogas and 5% (11.7 million) - for hydrogen. In the United States, 15 billion dollars a year are allocated to stimulate the NGV business.

Including 2.5 billion - for development programs and demonstration of achievements; 300 million - to the federal government for the purchase of NGVs for office needs; 300 million - to replace diesel school buses with environmentally friendly vehicles using gas engine and other alternative fuels; 300 million - for grants for Pilot projects within the framework of the "Clean City" program; 8.4 billion - for the purchase of new municipal buses and 3.2 billion - for grants in the field of energy conservation11.

Measures to stimulate the transfer of vehicles to NGV fuel

Australia, UK, Canada, Malaysia, Japan | Allocation of grants and subsidies for the purchase of vehicles running on natural gas, gas equipment. |

UK, Italy, Chile, China | Non-proliferation of the ban on entry into protected areas for vehicles running on gas. |

Restrictions on the use of hydrocarbon motor fuels, excluding municipal buses and refuse collection vehicles. |

|

France, Italy, Iran | Providing enterprises using compressed natural gas with a preemptive right to receive a municipal order. |

Obligatory purchase of gas-cylinder vehicles by budgetary organizations when renewing their vehicle fleet. |

|

There is a zero tax on methane-fueled vehicles. Until 2013, the state provides subsidies for the purchase of "gas" buses. |

If the above-mentioned measures of state stimulation contribute to the development of the methane fuel market abroad, in Russia this is not the case. The only such measure was the Government Decree No. 31 "On urgent measures to expand the substitution of natural gas for motor fuels" of 1993. In particular, it established a maximum selling price for CNG for the period of validity of regulated prices for natural gas in an amount not exceeding 50% of the price of A-76 gasoline, including VAT.

In addition, in Europe and the United States, regulations on the use of natural gas are included in the package of national standards. And in Russia all this is also not present. Moreover, the Russian Federation has not yet created even a regulatory framework regulating the use of methane as a motor fuel. Hence the incidents when companies transporting compressed methane are forced to paint the inscription "propane-butane" on gas carriers in order to avoid litigation with the traffic police, whose employees know about the regulations for the transportation of LPG, but the transportation of unregulated CNG is perceived almost as the transportation of dynamite.

At the end of 2010, Russian Prime Minister Vladimir Putin held a meeting on the development of the gas industry until 2030, which resulted in the following incentives for the transition to gas vehicles:

The emergence of the Federal Law "On the use of gas types of motor fuel";

Comprehensive assessment of the demand for NGV equipment until 2030;

Formation of a national coordinating body;

Monitoring the implementation of Federal Law No. 261 "On Energy Saving and on Increasing Energy Efficiency and on Amendments to Certain Legislative Acts of the Russian Federation" and orders of the Government of the Russian Federation of November 17, 2008, No. 1662-r and 1663-r;

Preparation of the federal target program "Alternative fuel for transport and agricultural machinery for 2012 - 2020." and FTP "White Olympics - blue fuel";

Long-term state order for the purchase of gas-cylinder vehicles for the public sector.

1 Gas industry, 2011, No. 3